Coating, coating liquid and application thereof to preparation of heat-doesn't-burn dry-method reconstituted tobacco

A technology of heat-not-burn and reconstituted tobacco leaves, which is applied in the application field of coating materials and dry reconstituted tobacco leaves, to achieve the effects of good thickness and fullness, high satisfaction and comfort, and high smoke concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

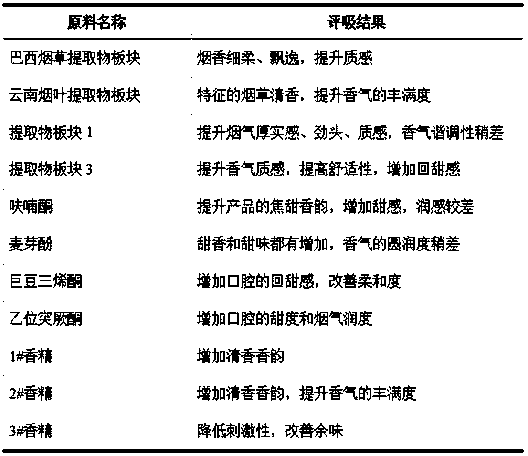

[0041] Example 1 Optimization experiment of flavors and fragrances

[0042] Different combinations of spices will bring different sensory evaluations. The present invention is to obtain coating materials with the following effects: (1) Strengthen the product's fragrance style characteristics; (2) Increase the thickness and fullness of the smoke; (3) ) Increase energy and increase satisfaction; (4) Improve the comfort of suction, and evaluate the flavors and fragrances. Based on the formula of the following tobacco powder and leaf group: Kunming fragments SM1 5%, Dali fragments SP3 20%, Qujing fragments SP1 5%, Yuxi fragments SM1 25%, Changde fragments 15% and Dali fragments SP1 30%. Small test sample (no coating material, as a control sample), and each flavor and fragrance were added to the sample at a use ratio of 1.5% to 2.0% for evaluation. The results are shown in Table 1 below.

[0043] The production process of dry test samples is as follows:

[0044] (1) Preparation of tobac...

Embodiment 2

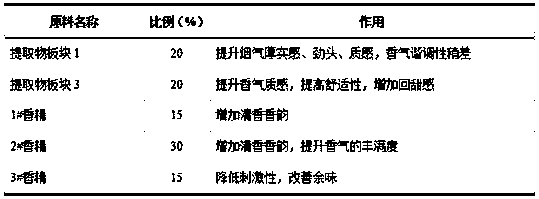

[0058] Example 2 Optimization experiment of coating material usage ratio

[0059] The coating material formula 1-1 shown in the following table 2 was applied to dry-process reconstituted tobacco with product mass fractions of 8.0%, 10.0%, 12.0%, 15.0% and 18.0% (relative to the coating liquid) respectively , Prepare small test samples and conduct sensory quality evaluation. The results are shown in Table 3.

[0060] Table 2 Coating material formula 1-1

[0061]

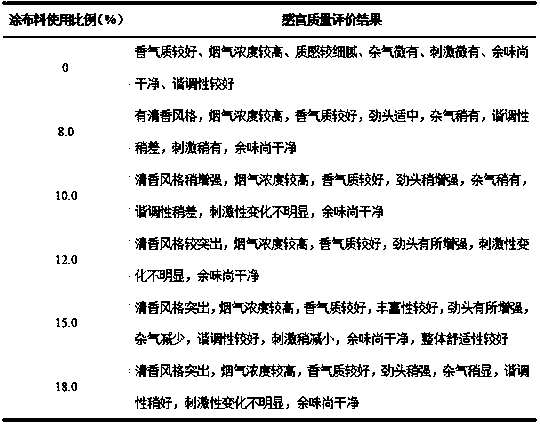

[0062] Table 3 Sensory quality evaluation of coating material 1-1 application sample

[0063]

[0064] It can be seen from Table 3 that with the gradual increase in the amount of coating material, the fragrance style of the small test sample becomes more and more prominent, but the addition of the coating material makes the sample's level of odor, irritation, and harmony slightly decreased. Relatively speaking, the use amount of 15.0% coating material is more suitable. The sample has outstanding fragrance style, high smoke c...

Embodiment 3

[0065] Example 3 Optimization experiment of coating material formulation components

[0066] According to the test results of the coating material formula 1-1, the coating material formula is adjusted to the component ratio, and the design is as shown in Table 4:

[0067] Table 4 The proportion adjustment design of coating material

[0068]

[0069] Prepare coating materials 1-2, 1-3, 1-4, 1-5, 1'-1, 1'-2, 1'-3, 1'-4, 1'-5 and A small sample was prepared with a use ratio of 15.0%, and the sensory quality evaluation was performed. The results are shown in Table 5 below.

[0070] Table 5 The sensory quality evaluation results of the coating material component ratio adjustment sample

[0071]

[0072] It can be seen from Table 5 above that, compared with coating material 1-1, the sensory quality of the other samples with adjusted coating material component ratios varies. Coating materials 1-2 and 1-3 are mainly inferior in terms of impurity, aroma, strength, etc. The overall sensory qual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com