Device for conveniently shaping titanium light alloy material

A light alloy and sprinkler technology, applied in the medical field, can solve the problems of single function and can not meet the needs of use, and achieve the effects of easy demoulding, easy shaping, and increased deformability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are listed below, and detailed descriptions are as follows in conjunction with the accompanying drawings.

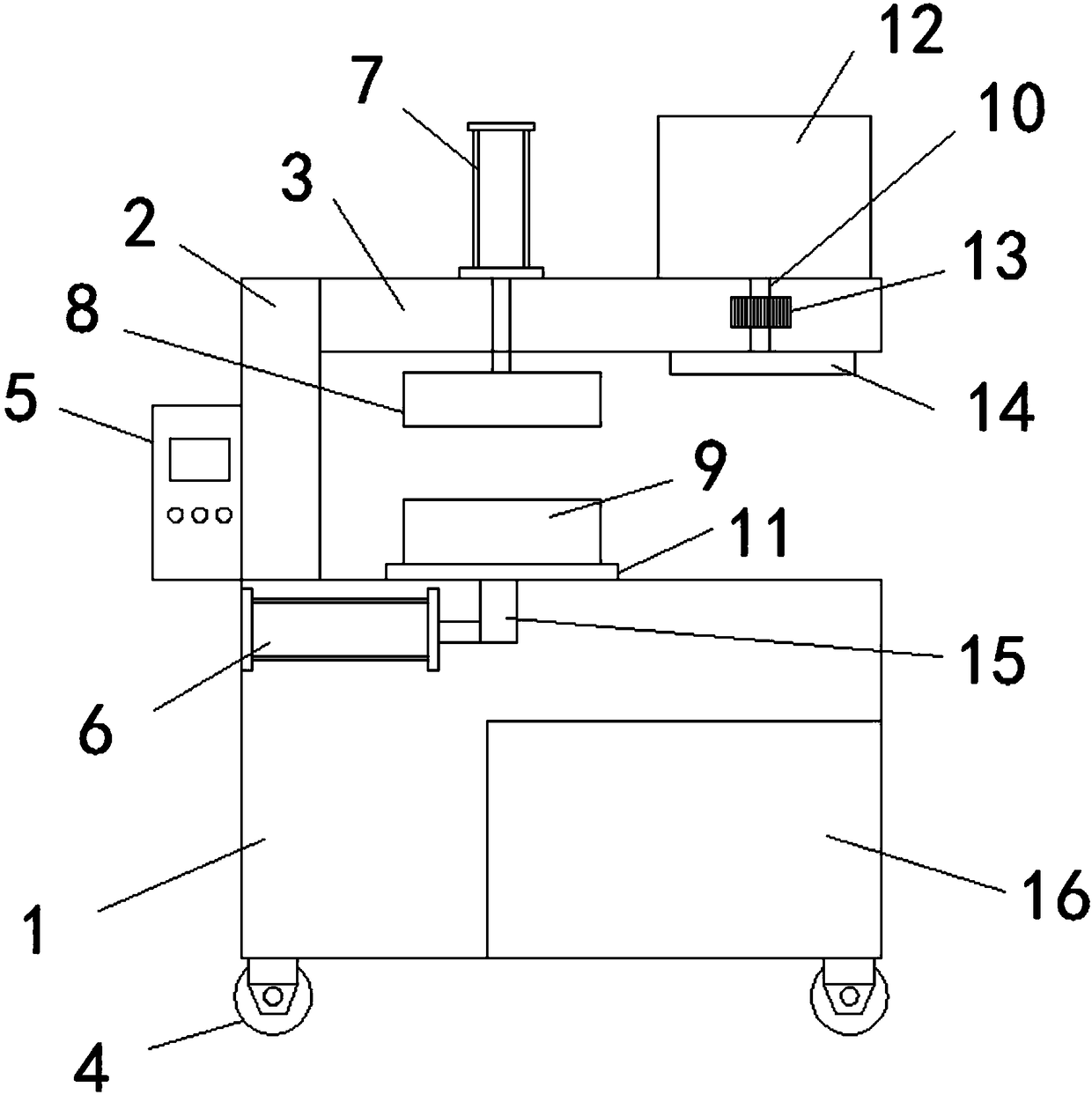

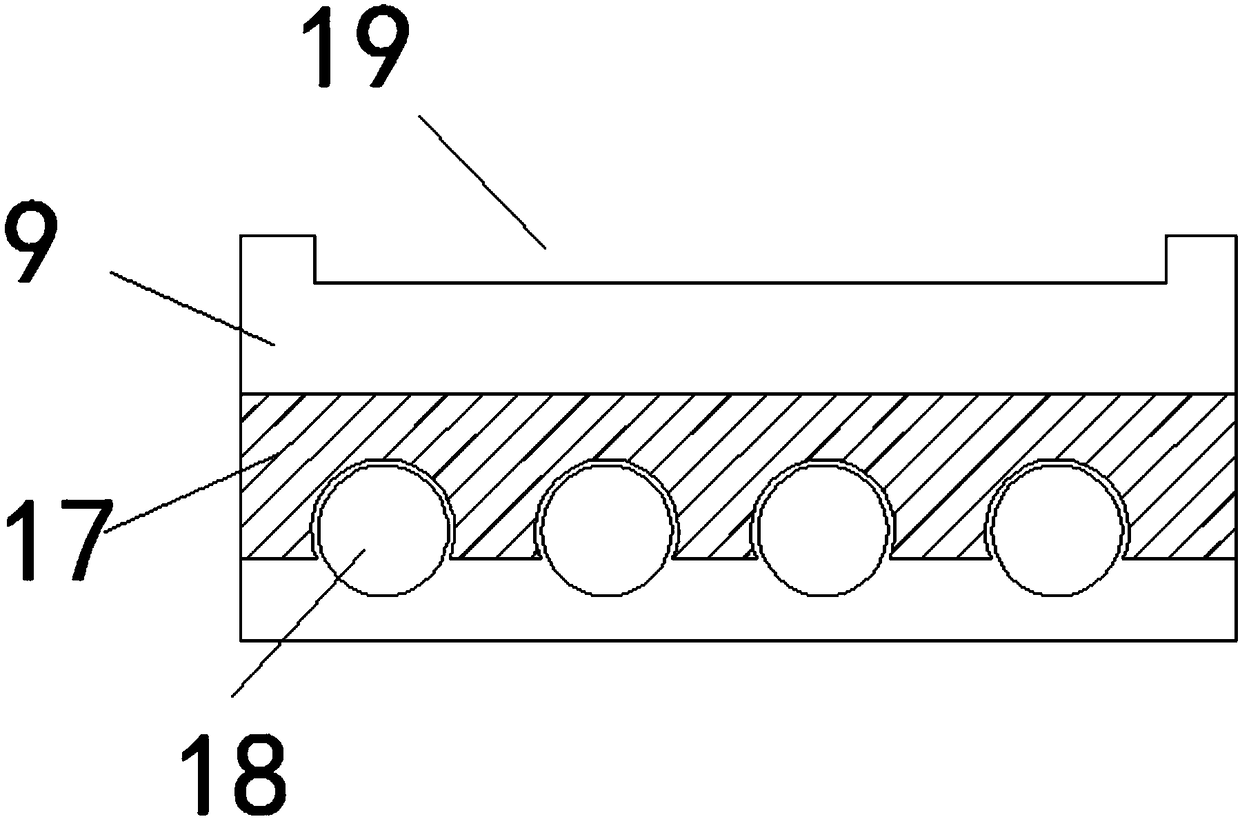

[0016] Combine below Figure 1-2 A detailed description is given to the structure of a titanium light alloy material shaping device of the present invention: a titanium light alloy material shaping device includes a device main body 1, a bracket 2, a fixed plate 3 and a walking wheel 4, the device The four corners of the bottom surface of the main body 1 are provided with walking wheels 4, and one side of the upper surface of the device main body 1 is provided with a support 2, and the support 2 is fixedly connected with a fixed plate 3 arranged parallel to the device main body 1, and the device main body 1 The upper surface of the upper surface is provided with a lower mold 9, the lower end of the lower mold 9 is provided with a sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com