Method for changing ordinary horizontal boring machine into precise numerical control horizontal machining center

A horizontal boring machine, precision numerical control technology, applied in the direction of metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low workpiece position accuracy, failure to achieve the expected effect, low processing efficiency, etc., to improve processing The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

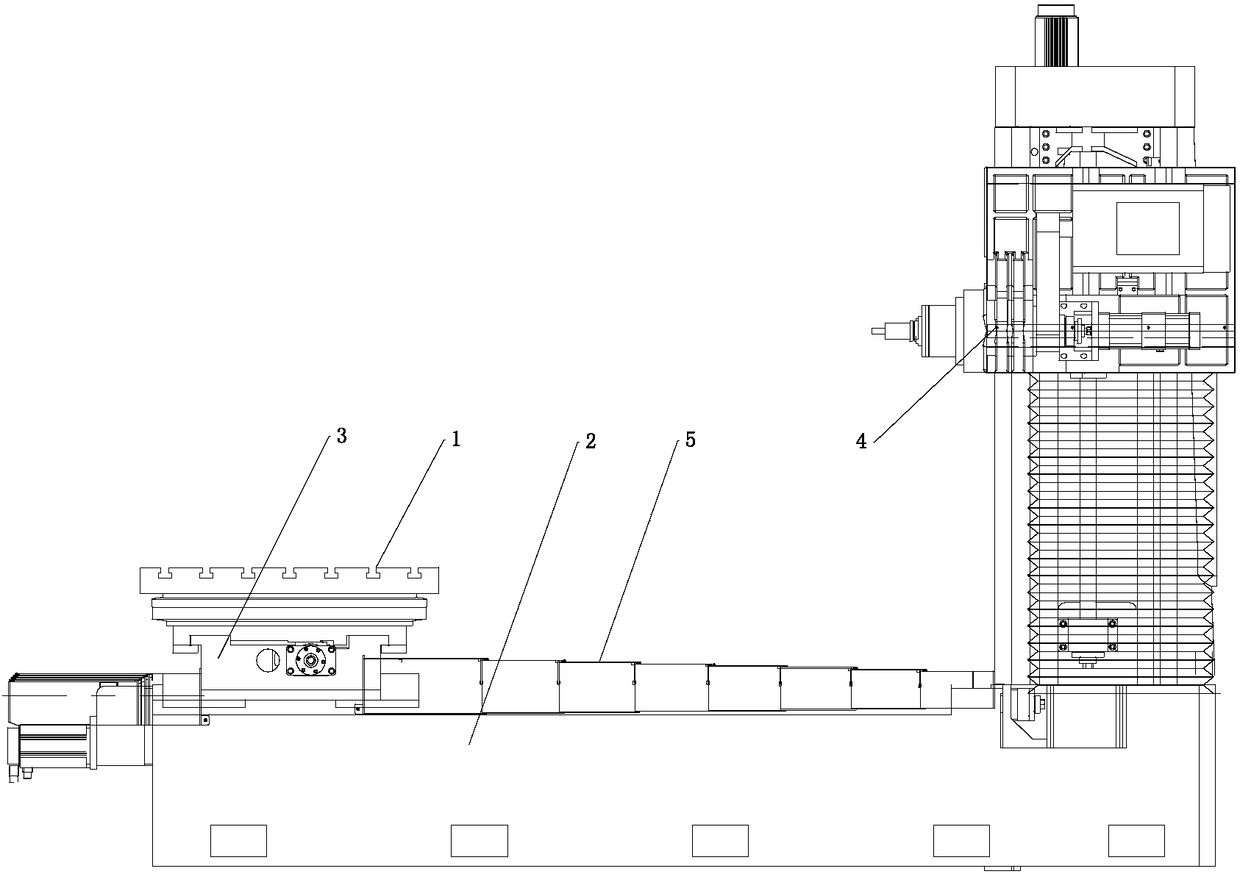

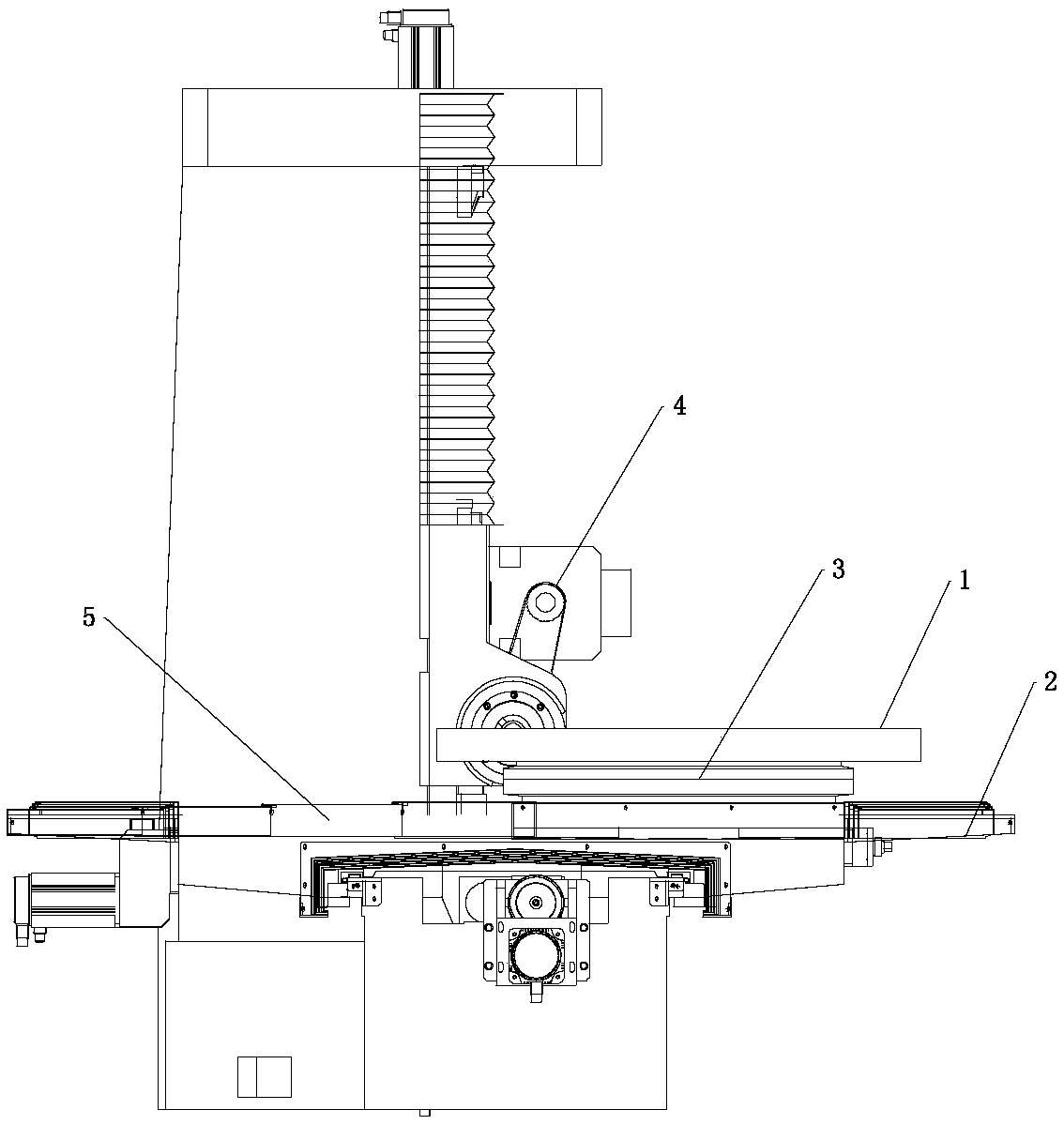

[0019] Such as figure 1 The shown method of changing an ordinary horizontal boring machine into a precision CNC horizontal machining center includes the following steps:

[0020] a. Removal: remove the T-shaped screw rods on each rolling guide rail 2, and then grind the worktable 1, each rolling guide rail 2 and the corresponding slider 3 on the boring machine;

[0021] b. Installation: Install ball screws on each rolling guide rail 2, and install a lubrication system on each rolling guide rail 2, and install it into the hydraulic tool magazine 4;

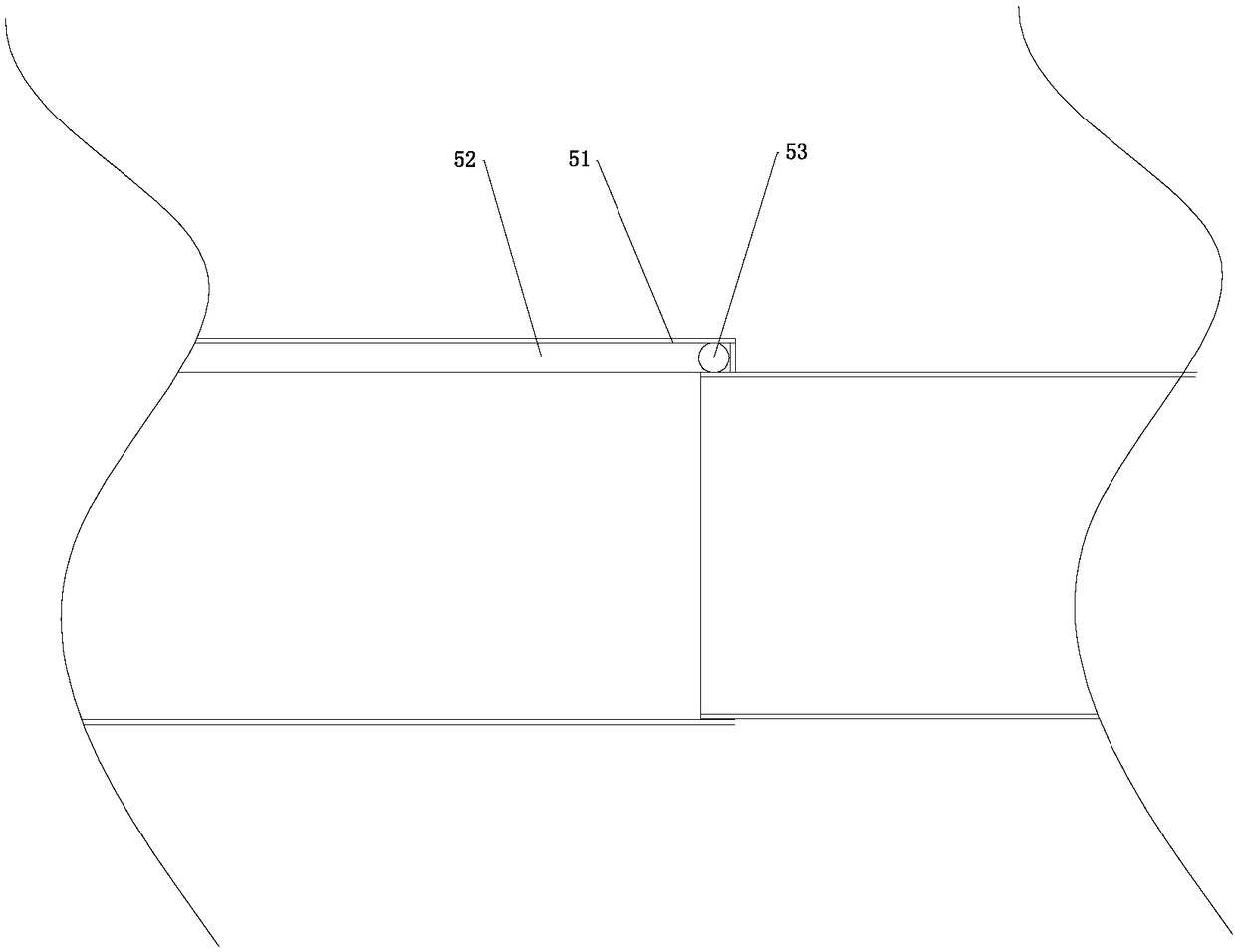

[0022] c. Protection: Install a protective cover 5 on each rolling guide rail 2, so that the protective cover 5 covers the ball screw on the corresponding rolling guide rail;

[0023] d. Drive: Install the circuit, gas circuit and supporting control system for the application. The control system is a PLC control box, and the staff will input the pre-designed PLC program into the PLC control box, and then the PLC controls the oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com