Method for simply demounting copper tile from cylinder body of hydropower unit

A technology for hydroelectric units and cylinders, applied in hand-held tools, manufacturing tools, etc., can solve the problems of not being able to meet the actual needs of repairs, difficulty in reassembling new copper tiles, and easy damage to the cylinder body, so as to ensure quality and Appearance, easy promotion, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

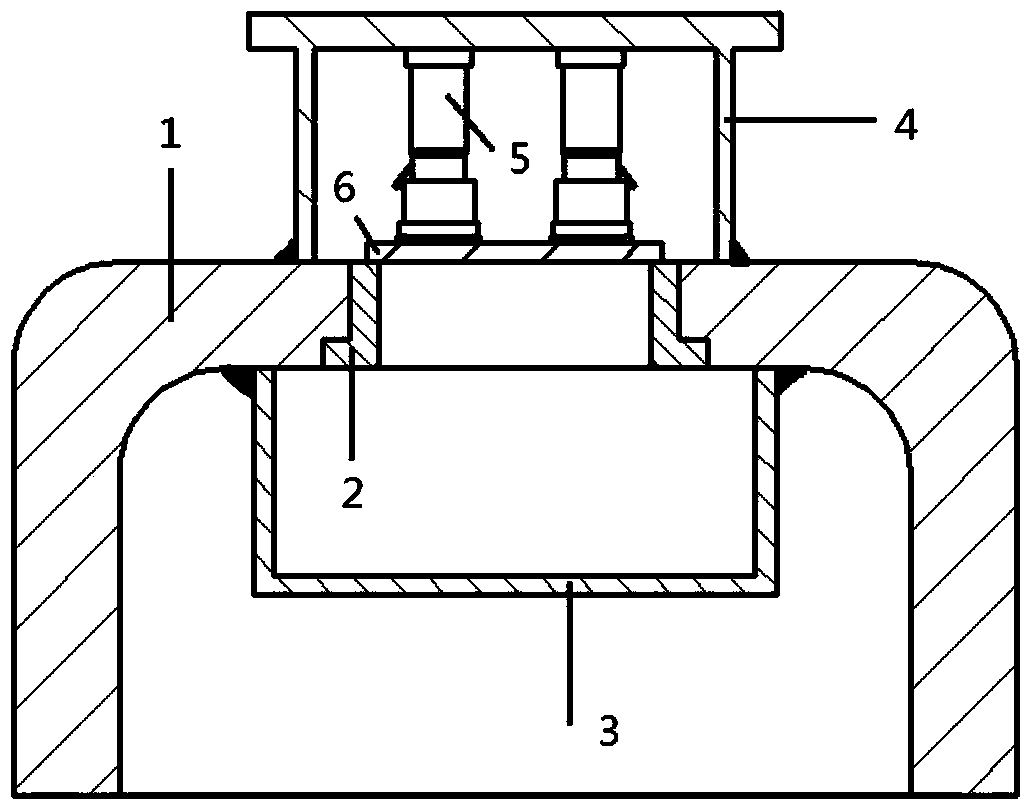

[0030] Taking the repair work of a cylinder block of a large hydropower unit as an example to illustrate the process of removing copper tiles by applying the present invention: the weight of the cylinder body is 25t, the height is about 832mm, the maximum outer diameter is Ф1275mm, the maximum outer diameter of copper tiles is Ф375, and the copper tiles Height 120mm. Adopt the present invention to remove, and process is as follows:

[0031] 1) Place the cylinder body 1 on the ground, with the flange end of the copper tile 2 facing down, and weld the container tube 3 with a height of 150mm under the cylinder body 1;

[0032] 2) Pour 700ml of liquid nitrogen from the upper opening of the cylinder into the space formed by the cylinder 1, the copper tile 2 and the container cylinder 3;

[0033] 3) Put the pressure bearing plate 6 on the upper end of the copper tile 2;

[0034] 4) Put the jack 5 on the upper part of the pressure plate 6, adjust the height of the jack 5, put the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com