Die for processing automobile diamante strip

A technology of bright trim strips and molds, applied in the field of auto parts processing, can solve the problems of reducing product quality, extruding light distortion, affecting the normal use of products, etc., to ensure product quality, avoid position offset, and avoid flash defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

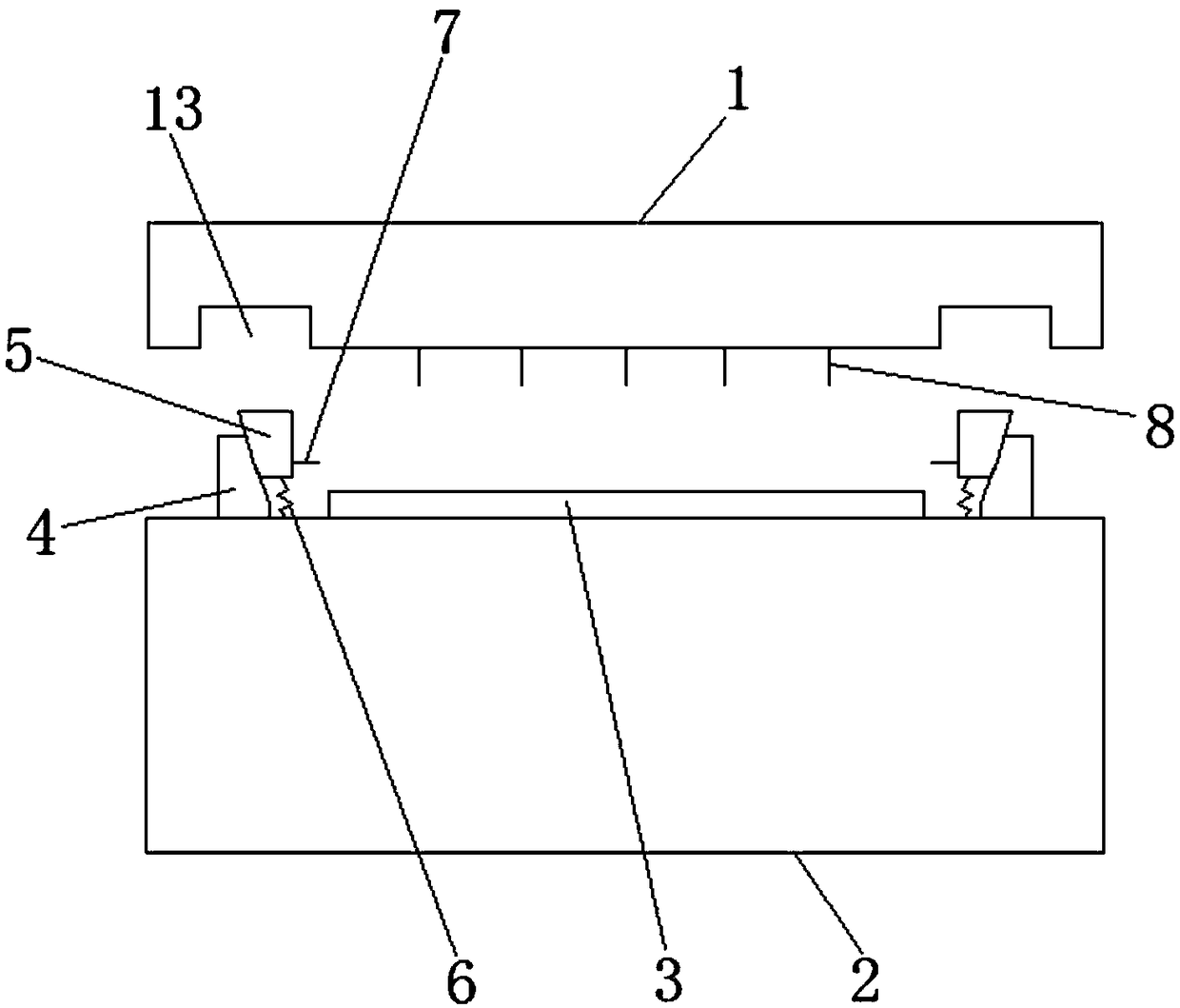

[0025] Such as figure 1 A kind of mold that is used for the processing of bright decorative strips shown in the car comprises upper mold base 1 and lower mold base 2, and lower mold base 2 is provided with the mold cavity 3 that matches with bright decorative strips and a plurality of respectively arranged in the mold A horizontal elastic thimble mechanism adapted to the cavity 3 and around the cavity 3, and a vertical elastic thimble mechanism adapted to the cavity 3 is provided at the bottom of the upper mold base 1. A magnet is arranged in the mold cavity 3 .

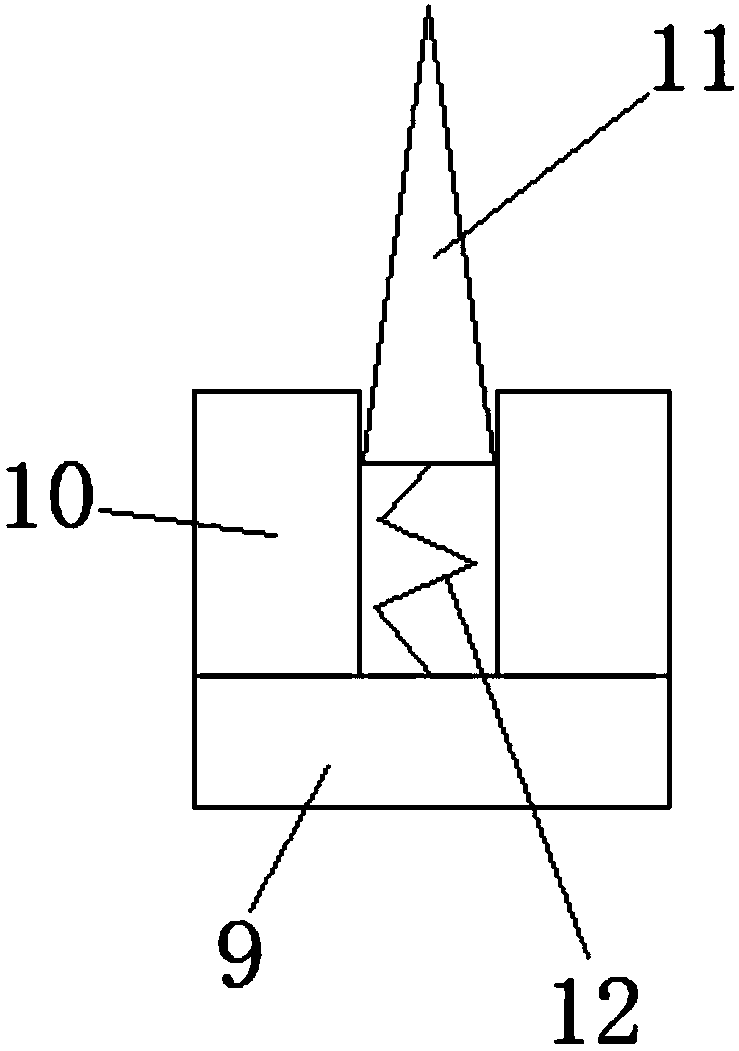

[0026] Wherein, the horizontal elastic thimble mechanism includes a guide block 4 arranged on the lower die base 2, a slide block 5 slidably arranged on the guide block 4, a slide block return spring 6 arranged between the slide block 5 and the lower die base 2, and a set A horizontal ejector pin 7 on the side of the slider 5 and adapted to the mold cavity 3 . The guide block 4 is provided with a guide block slope,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com