Overturning material-dumping device

A technology of feeding device and turning mechanism, which is applied in packaging, loading/unloading, transportation and packaging, etc., can solve the problems of inconvenient efficiency, inability to meet automated production, and low efficiency of manual lifting, and achieve convenient operation and high work efficiency. 、Easy and labor-saving effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

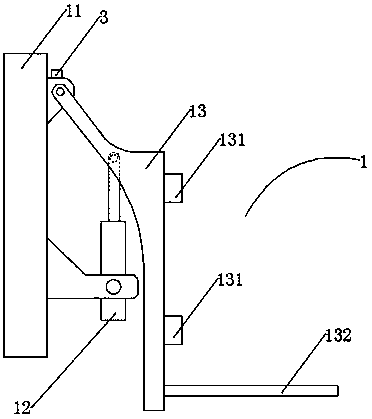

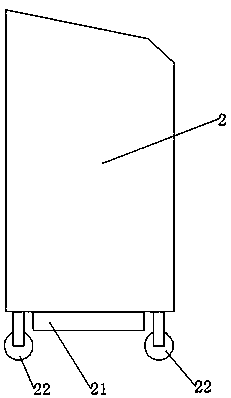

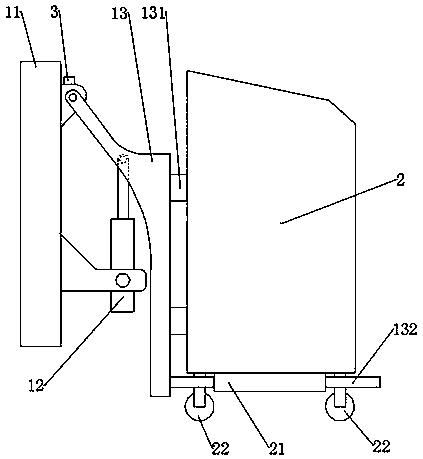

[0020] refer to Figure 1~4 , a turning and unloading device, including a turning mechanism 1 and a hopper 2, the turning mechanism 1 is used to drive the hopper 2 to a high place, the hopper 2 is used to hold materials, and the hopper 2 can be set as an upper opening, which is suitable for holding more For long-distance transshipment, the hopper 2 can also be set to be open on both the upper part and one side, which is suitable for short-distance transshipment and needs to be loaded by shoveling and then flipped and unloaded. The hopper 2 is movably installed on the overturning mechanism 1, so that the full hopper can be directly installed with the overturning mechanism 1, and then the overturning and unloading is completed. After the unloading is completed, the hopper is unloaded and the next full hopper is installed The flipping and dumping realizes that the dumping does not need to transfer the material to the buffer hopper, and directly uses different hoppers to continuou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com