Gas drainage method for pressure relief by group of high-level directional drilling holes on the roof of coal mining face

A coal mining face and directional drilling technology, which is applied in directional drilling, gas discharge, mining equipment, etc., can solve problems such as difficult resource utilization of gas, construction conditions affected by topography, and inability to guarantee the extension of drilling trajectory, etc. , to achieve the effects of resource utilization, real-time controllable drilling trajectory, and good gas drainage effect

Active Publication Date: 2019-10-01

XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The excavation of high-level pumping roadway requires a large amount of excavation, long construction period, and high cost; the pipeline of the return air buried pipe is easily crushed by the overlying rock that falls across, and the drainage effect is not good; The drilling trajectory is uncontrollable, and the drilling trajectory cannot be guaranteed to extend in the fracture zone; the construction of L-shaped wells in the ground mining area is difficult and costly, and the construction conditions are affected by the topography

In addition, the existing methods of gas drainage in the goaf of the working face can only extract the gas in the air-conducting fracture zone of the goaf, and this part of the gas is mixed with a large amount of air introduced by the ventilation of the working face, so it is difficult to realize resource utilization of the extracted gas

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

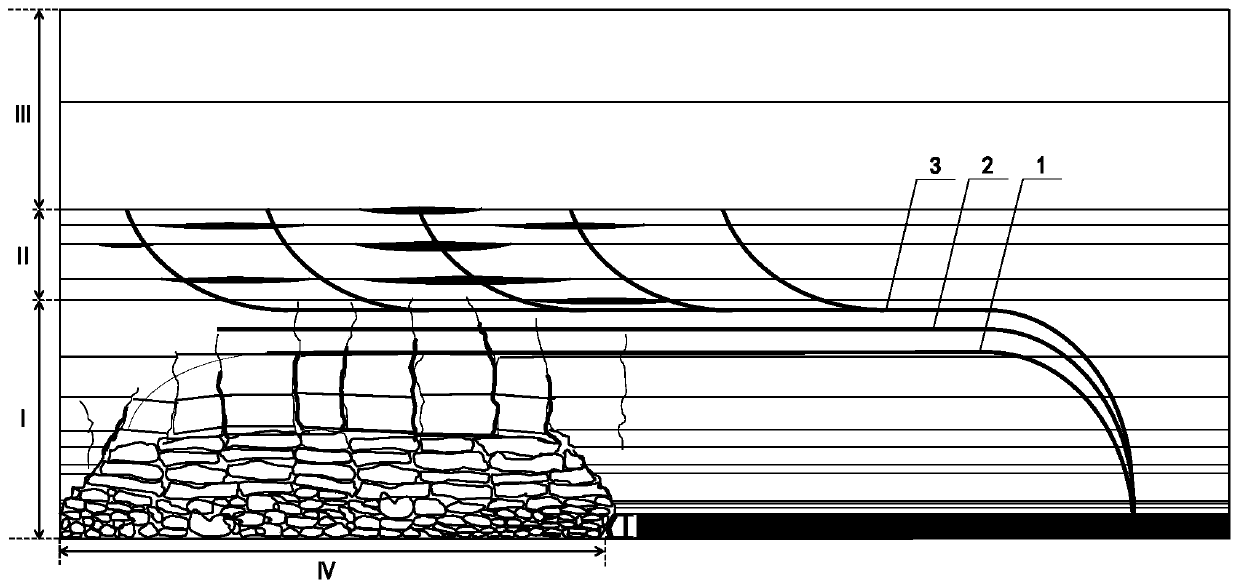

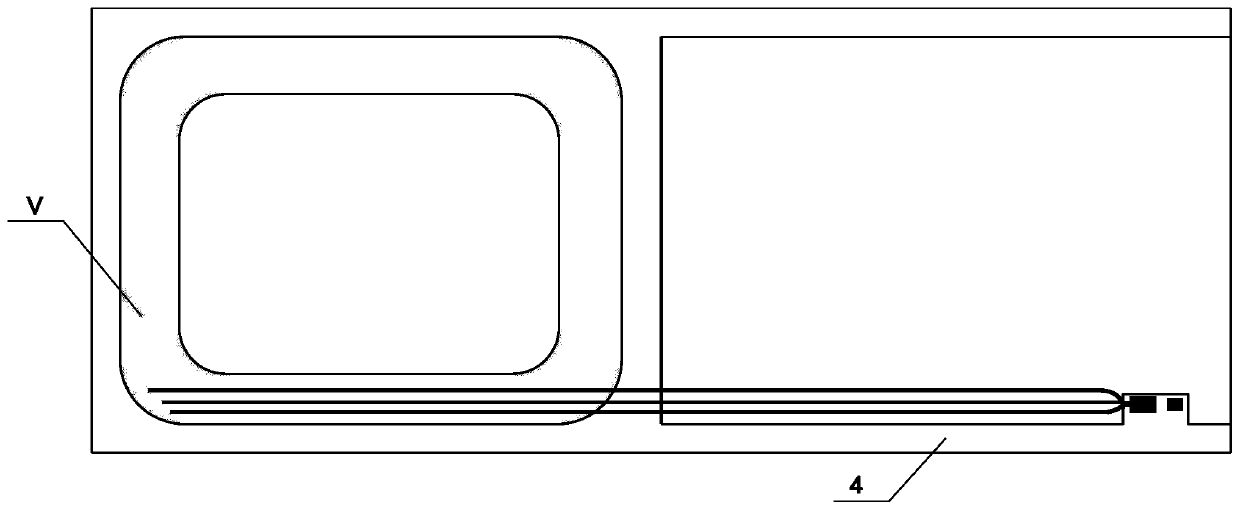

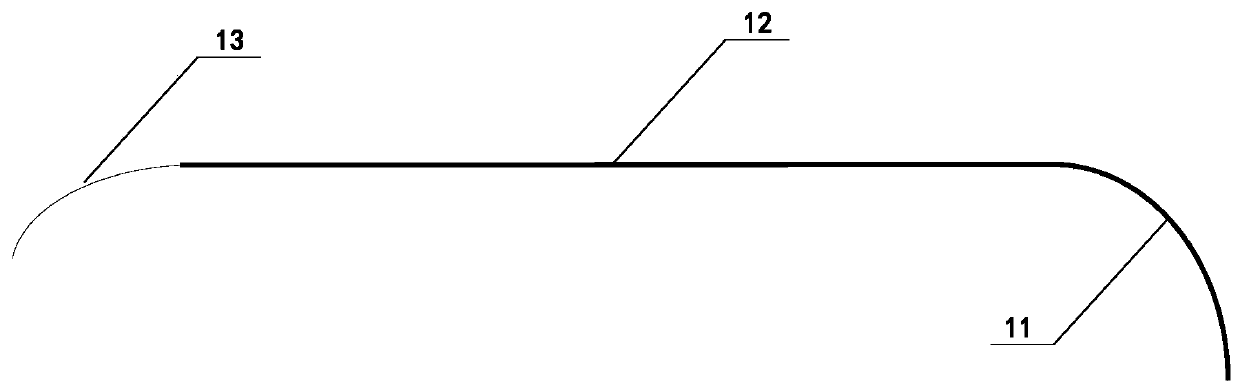

The invention discloses a pressure-relieving gas extraction method for a group of high-position directional drilling holes on the roof of a coal mining face. The principle is that before the mining of the working face, through the construction of high-level directional long drilling groups along the direction of the working face in the return air channel of the working face, the main hole sections of each high-level drilling are formed in the goaf after the mining of the working face The "O" ring is extended in the fissure zone, and the lower borehole is properly subsidence near the cutting hole of the working face, and the upward branch hole is constructed in the upper borehole. Gas in the gas-conducting fracture zone and the pressure relief and desorption zone after operation. This method can reduce the gas concentration in the upper corner of the working face and the return air flow, as well as drain the high-concentration gas in the pressure relief and desorption zone of the goaf, so as to achieve the goal of gas control on the working face and the recovery of gas resources.

Description

technical field The invention relates to a gas drainage method, which belongs to the field of underground gas control and gas drainage in coal mines, and in particular to a pressure relief gas drainage method for a group of high-level directional drilling holes on the roof of a coal mining face. Background technique The geological conditions of my country's coal fields are complex, which can easily lead to various major safety accidents. Among them, the gas associated with coal and existing in coal seams is one of the biggest disaster-causing factors that threaten the safety of my country's coal mines. At the same time, gas is a clean and efficient energy source. If these gas resources are effectively extracted, it will greatly alleviate the energy shortage in our country. Therefore, no matter from the perspective of ensuring mine safety production or resource utilization, coal mine gas should be extracted. During coal mining, due to the pressure difference between the inl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E21F7/00E21B7/04

Inventor 陈盼许超赵建国李泉新刘建林王四一方俊

Owner XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com