Advanced geological exploration device and method for directional drilling coal mine underground rock shield roadway

A technology of directional drilling and shielding, which is applied in directional drilling, tunnels, mining equipment, etc., can solve the problems of low precision and achieve the effects of precise trajectory control, expanded coverage, and long detection distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

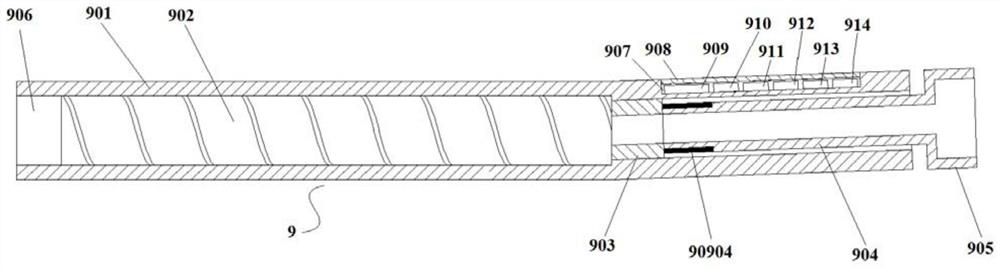

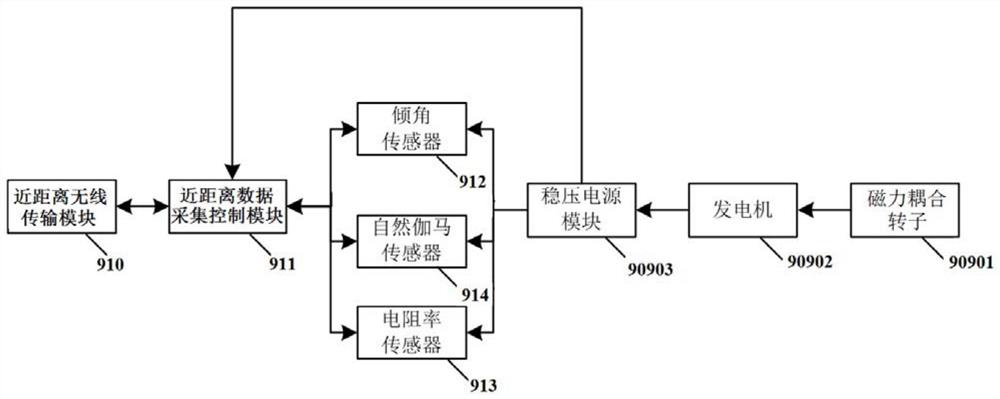

[0069] This embodiment provides an advanced geological exploration device for a directional drilling coal mine underground rock shield tunnel, such as Figure 2 to Figure 4 As shown, the device includes a mining dynamic formation detection instrument while drilling, and the mine dynamic formation detection instrument while drilling includes a short-range detection and transmission probe 9 and a long-distance signal transmission probe 10;

[0070] The short-range detection and transmission probe 9 includes a curved outer pipe 901, and the curved outer pipe 901 is provided with a screw 902, a universal torsion shaft 903 and a drive shaft 904 connected in sequence. The drill bit joint 905 to which the drill bit is connected, the rear end of the curved outer tube 901 is provided with a remote joint 906 for connecting with the remote signal transmission probe tube 10;

[0071] In this embodiment, the curved outer tube 901 , the screw rod 902 , the universal torsion shaft 903 and th...

Embodiment 2

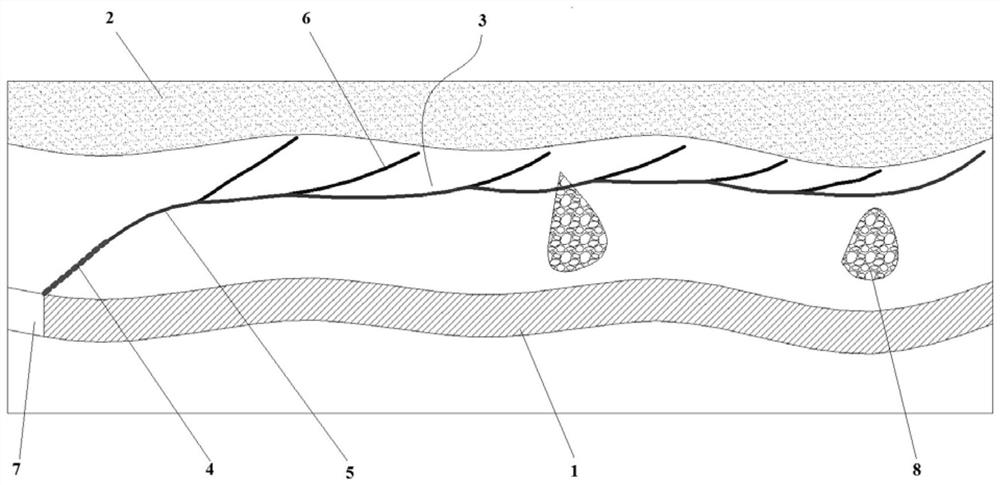

[0087] This embodiment provides an advanced geological exploration method for underground rock shield tunnels in directional drilling coal mines, such as figure 1 As shown, the method includes the following steps:

[0088] Step 1: Route design of shield tunnel 1:

[0089] According to the preliminary geological survey data of the mine and the layout of the mine working face, determine the control distance between the shield tunnel 1 and the coal seam 2, design the shield tunnel 1 line, and determine the spatial parameters of the control point according to the construction control requirements of the shield tunnel 1;

[0090] Step 2: Explore the directional drilling 3 design:

[0091] Taking the starting point of the shield tunnel 1 line as the opening point, design the exploration directional drilling hole 3, and determine the plane coordinate parameters and section coordinate parameters of the exploration directional drilling hole 3;

[0092] Step 3, explore the constructio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com