Spiral car lamp light-emitting unit

A technology of light-emitting units and lights, applied in the direction of headlights, semiconductor devices of light-emitting components, light sources, etc., can solve the problems of limiting the variety of changes in the shape of lights, unfavorable personalization and diversified choices of car manufacturers, etc., to improve the market. Competitive, artistic, and the effect of meeting individual needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

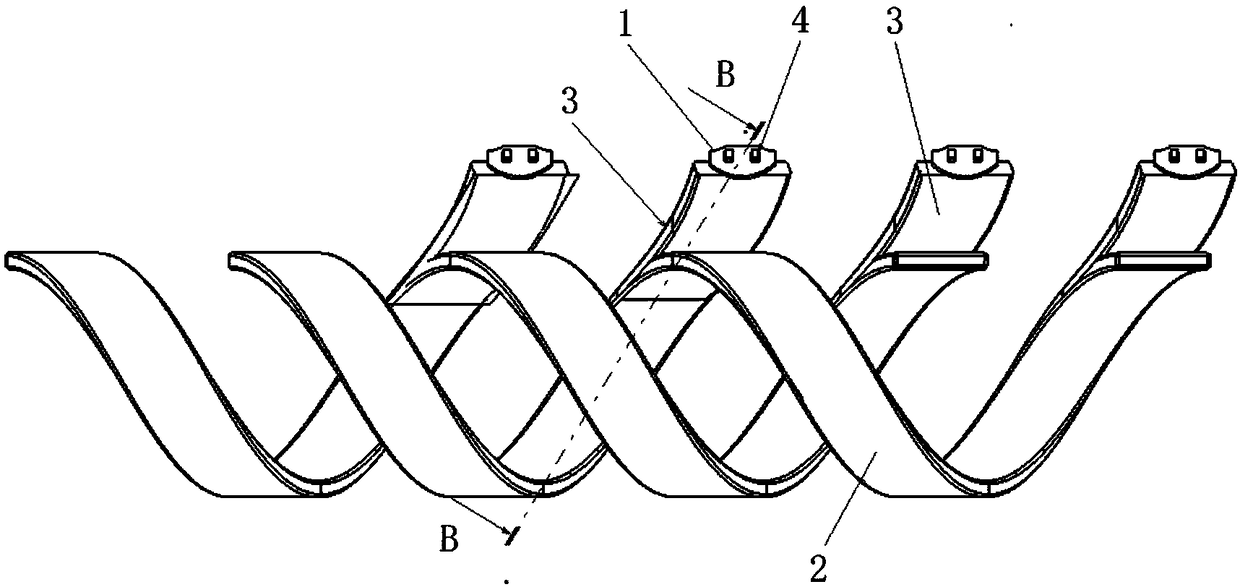

[0027] like Figure 3-8 As shown, the present invention discloses a spiral-shaped vehicle light emitting unit, which includes a light source 4 and a light guide strip. The light guide strip includes a spiral light guide strip main body 2 and a linear light guide strip light incident section 3. The light incident section of the light guide strip is connected to the main body of the light guide strip and is tangent to it along the extending direction of the main body of the light guide strip at the connection position. One end connected to the main body of the light guide strip on the light incident section of the light guide strip is the proximal end, and the other end is the far end. The light source is arranged on the circuit board assembly 1 , the circuit board assembly is fixedly arranged at the distal end, and the light emitting surface of the light source faces the end surface of the distal end.

[0028] The light guide strip is made of a material capable of guiding ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com