Circularity error offline measuring method

A roundness error, off-line measurement technology, applied in the direction of mechanical counter/curvature measurement, can solve the problems of workpiece roundness error, difficult to measure large-sized workpieces, etc., and achieve the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and example the present invention is further described;

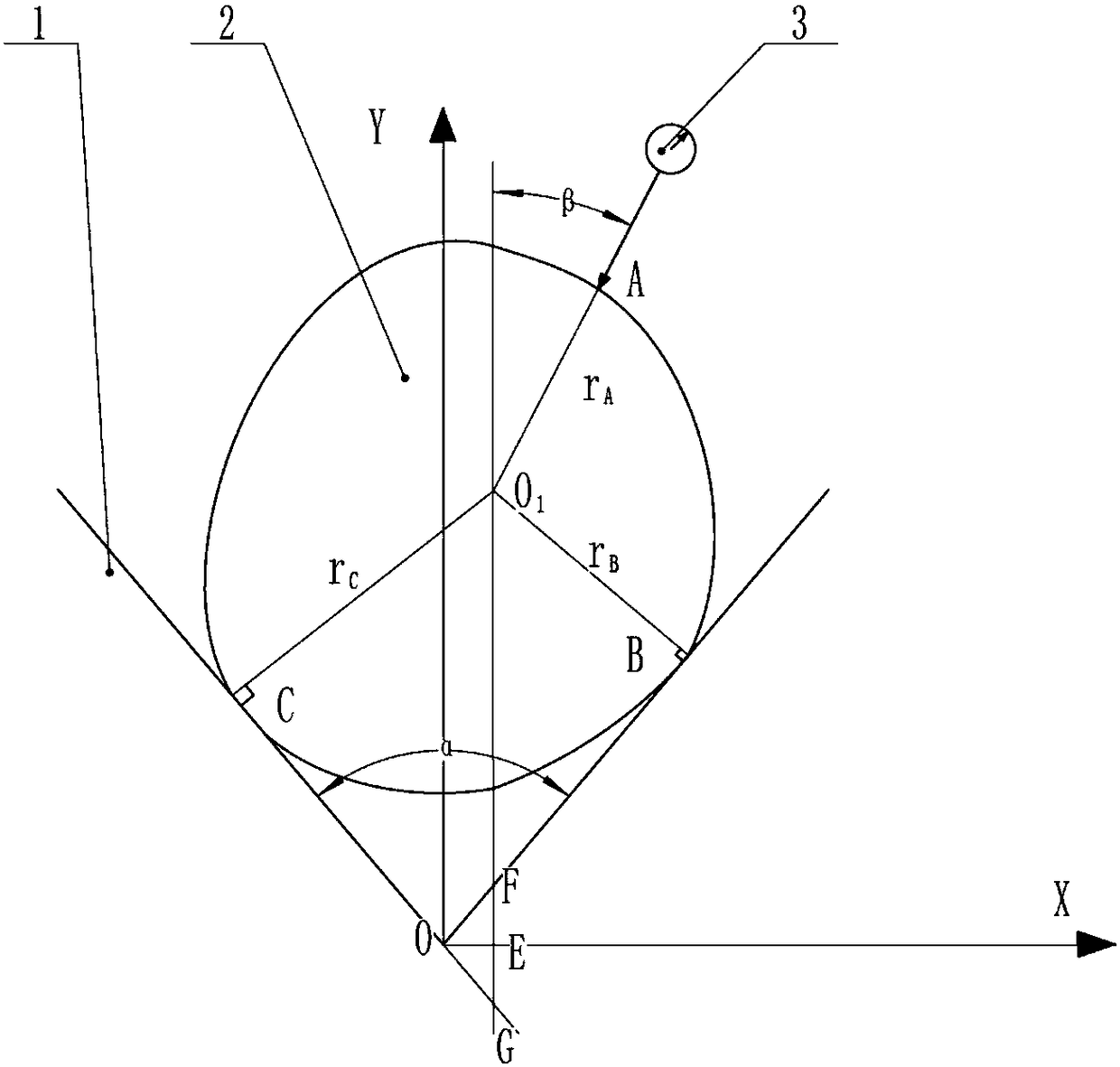

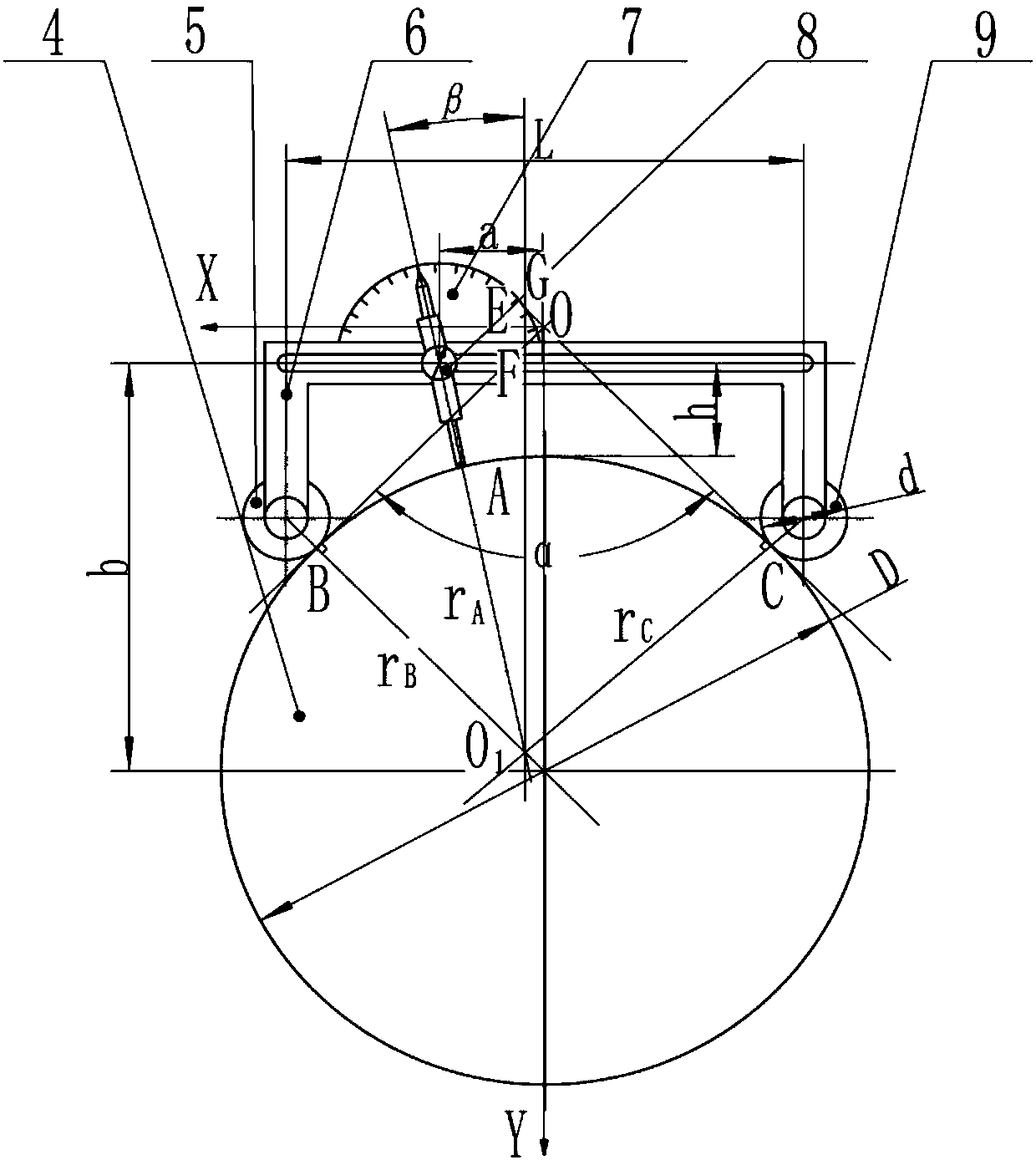

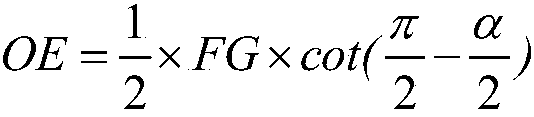

[0041] figure 2 Among them, the profile surface of the support wheel a5 is close to the workpiece b4 under test, the angle between the two support wheels and the common tangent to the workpiece under test is α, and the dial indicator b8 forms a certain declination angle β with the vertical direction and points to pass through the two supports at this time. The point of tangency between the wheel and the measured workpiece b4 is perpendicular to their common tangent intersection point (instantaneous circle center). The purpose of the dial indicator offset is to reduce the influence of harmonic loss on the measurement results. In the XOY coordinate system, A represents the position of the dial indicator b8, B and C are the contact points where the measured workpiece is tangent to the two supporting wheels of the measuring bracket b6, and O 1 is the instantaneous cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com