Three-dimensional topography measurement method capable of inhibiting indirect illumination

A three-dimensional topography, indirect technology, applied in the field of optical measurement, which can solve problems such as decreased accuracy and missing measurement data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

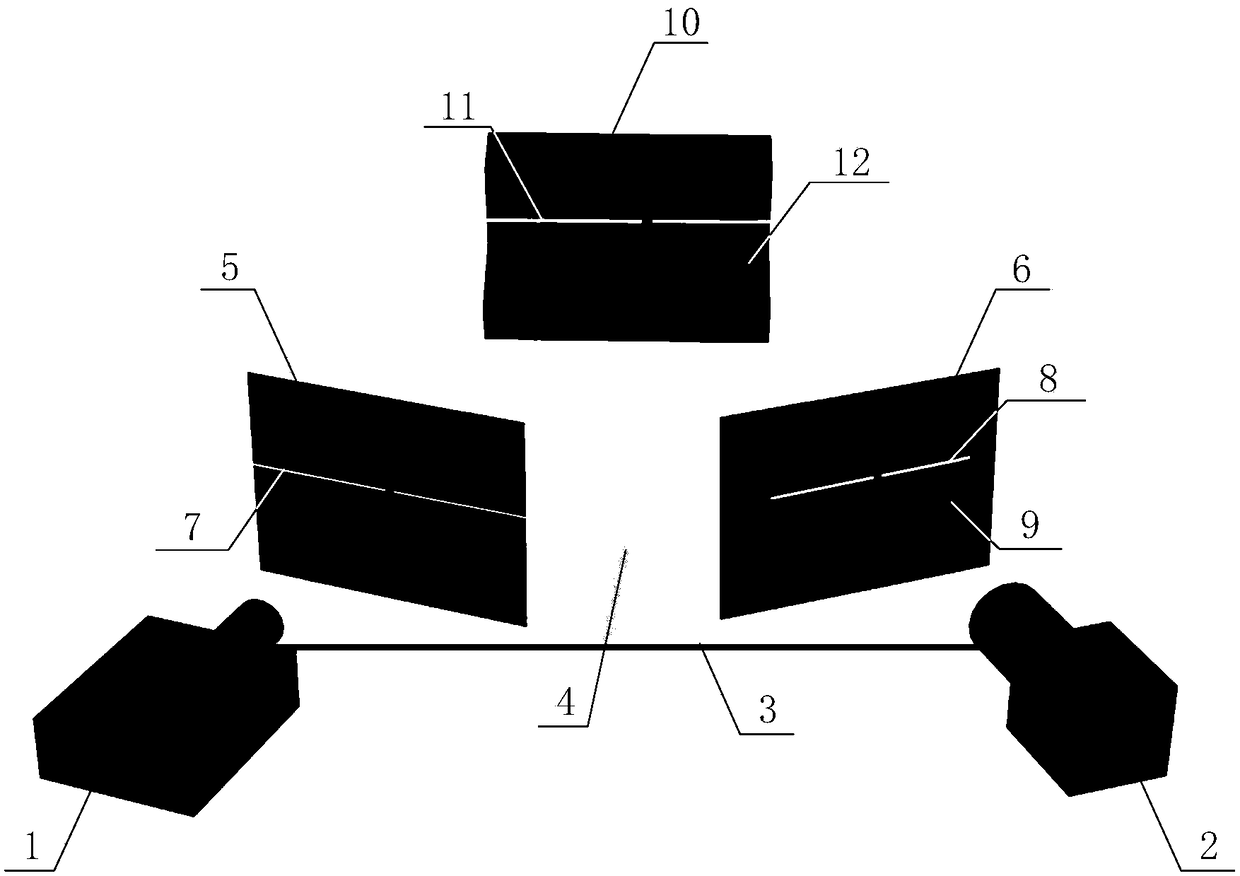

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] The present invention is based on a structured light three-dimensional shape measurement system, mainly composed of a projector and a camera, and the projector and the camera form a binocular stereoscopic vision system. The invention utilizes the principle of epipolar line geometry in binocular stereo vision, and the epipolar line geometry can be used to determine the corresponding relationship between the epipolar line on the projector and the camera. The invention does not need to modify the structure of the structured light three-dimensional shape measurement system, and does not need any additional optical and mechanical components.

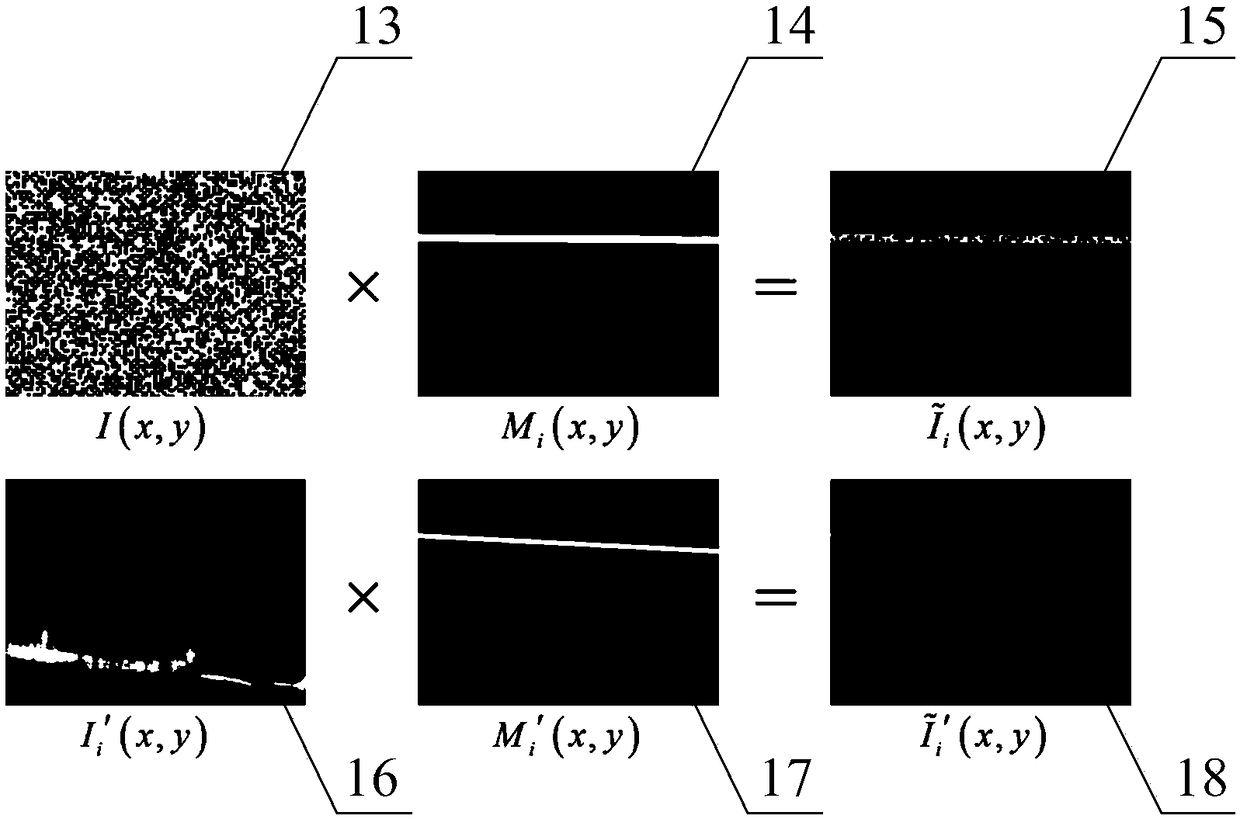

[0027] During the measurement process, a complete structured light pattern is divided into multiple projections, and only one epipolar line in the epipolar geometric relations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com