Automatic batch calibration device for micro-mano thermocouples

A calibration device and thermocouple technology, applied in the nano field, can solve the problems of incapability of encapsulation, high error rate, low efficiency, etc., and achieve the effect of improving calibration efficiency and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

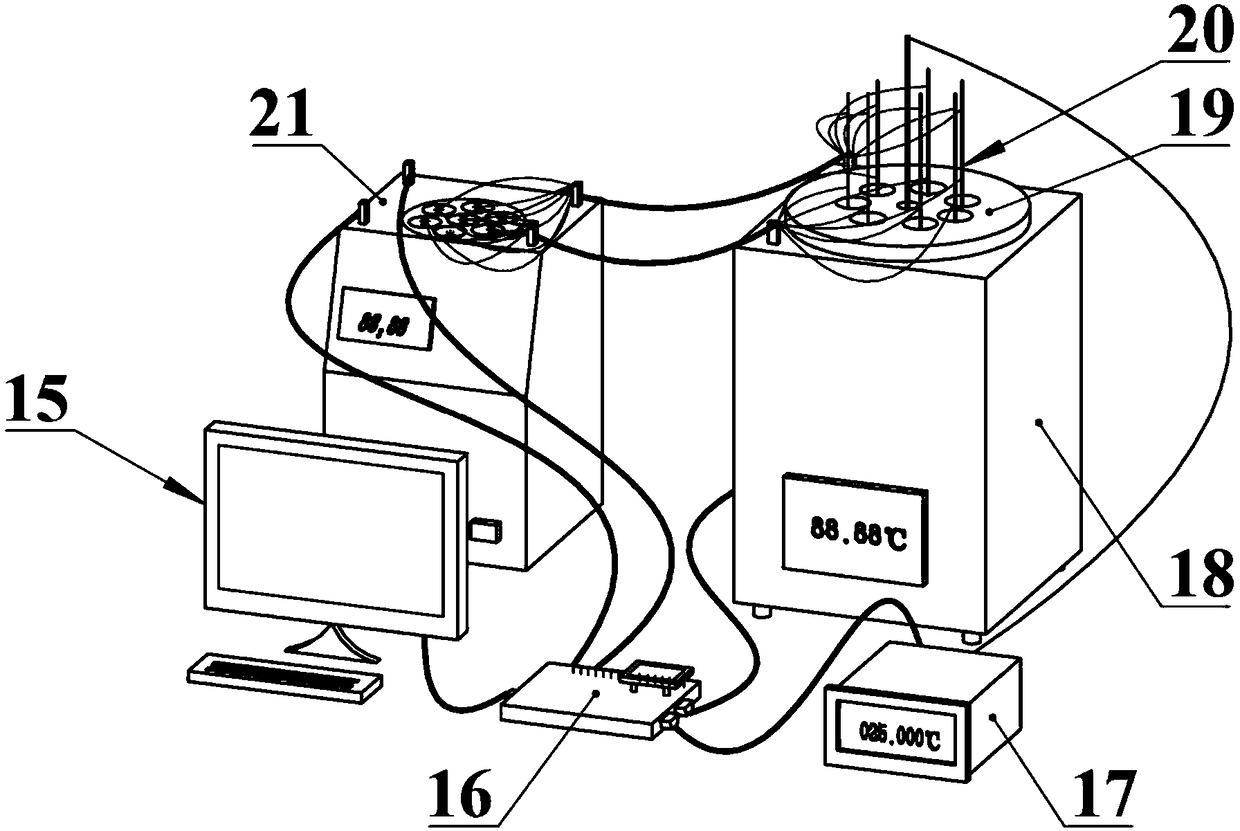

[0017] Such as figure 1 As shown, the micro-nano thermocouple automatic batch calibration device of the present invention comprises a temperature standard device 17, a constant temperature water bath 18, a zero-degree thermostat 21, a controller 16 and a computer 15; a temperature standard device 17, a constant temperature water bath 18 and a zero-degree thermostat The thermostats 21 are respectively connected to the controller 16 , and the controller 16 is connected to the computer 15 .

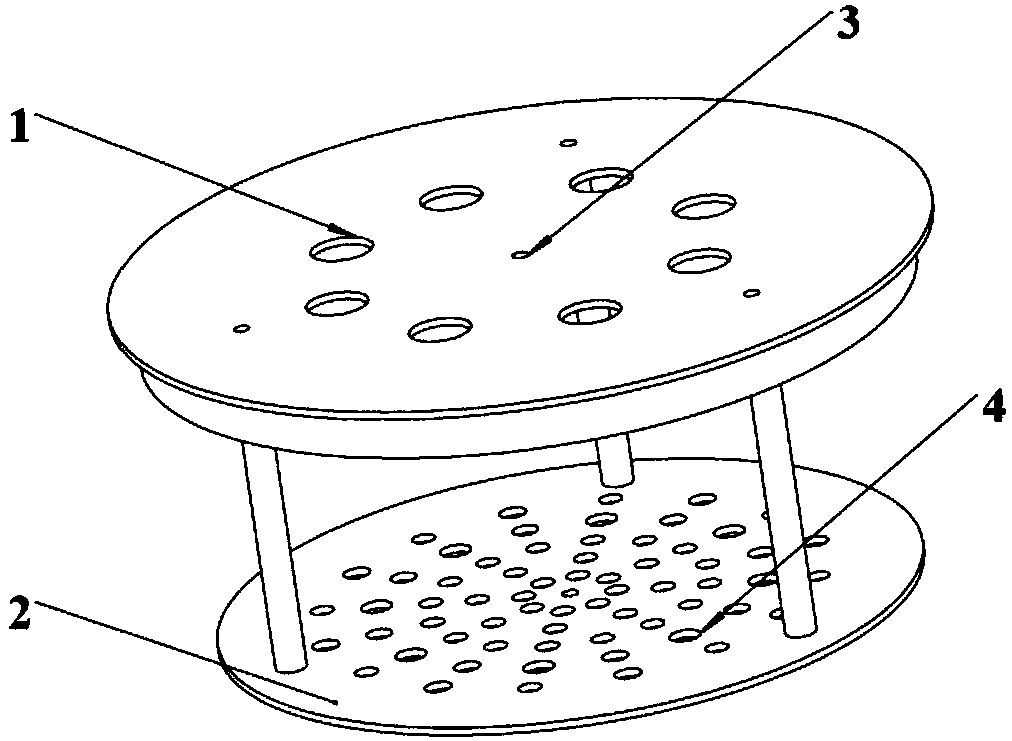

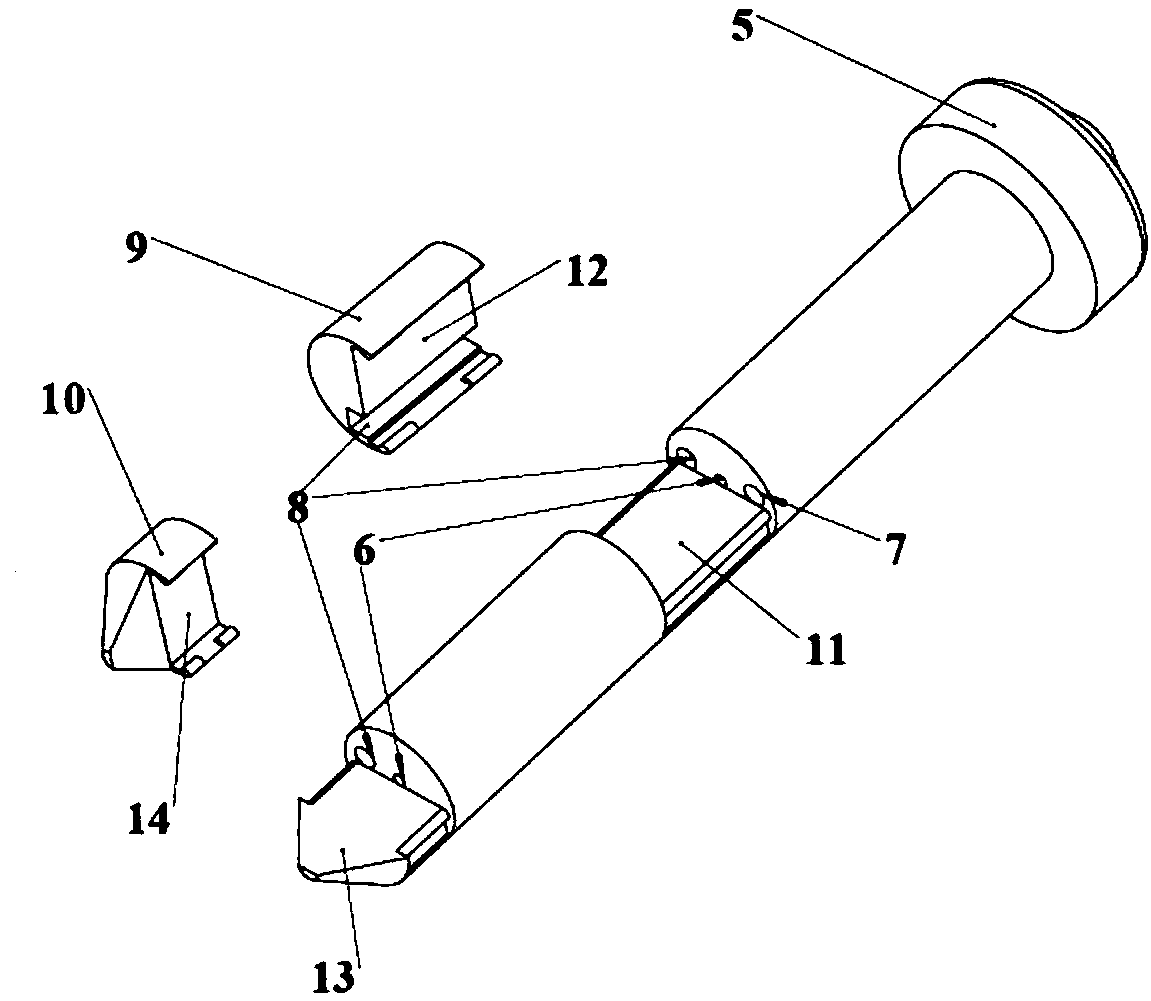

[0018] A calibration bracket 19 is provided above the constant temperature water bath 18, such as figure 2 As shown, the calibration bracket 19 includes a micro-nano thermocouple connector fixing hole 1 , a tray 2 , a water permeable hole 4 and a temperature standard device fixing hole 3 . The micro-nano thermocouple connector 20 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com