Scheduling sub-system of three-level production planning system for steel-making enterprises

A scheduling subsystem and production planning technology, applied in the field of scheduling subsystem, can solve problems such as inability to match the enterprise's consistent system, inability to adjust, and lack of accurate time concepts, etc., to achieve controllable production rhythm, reduce outage accidents, and high reliability operational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

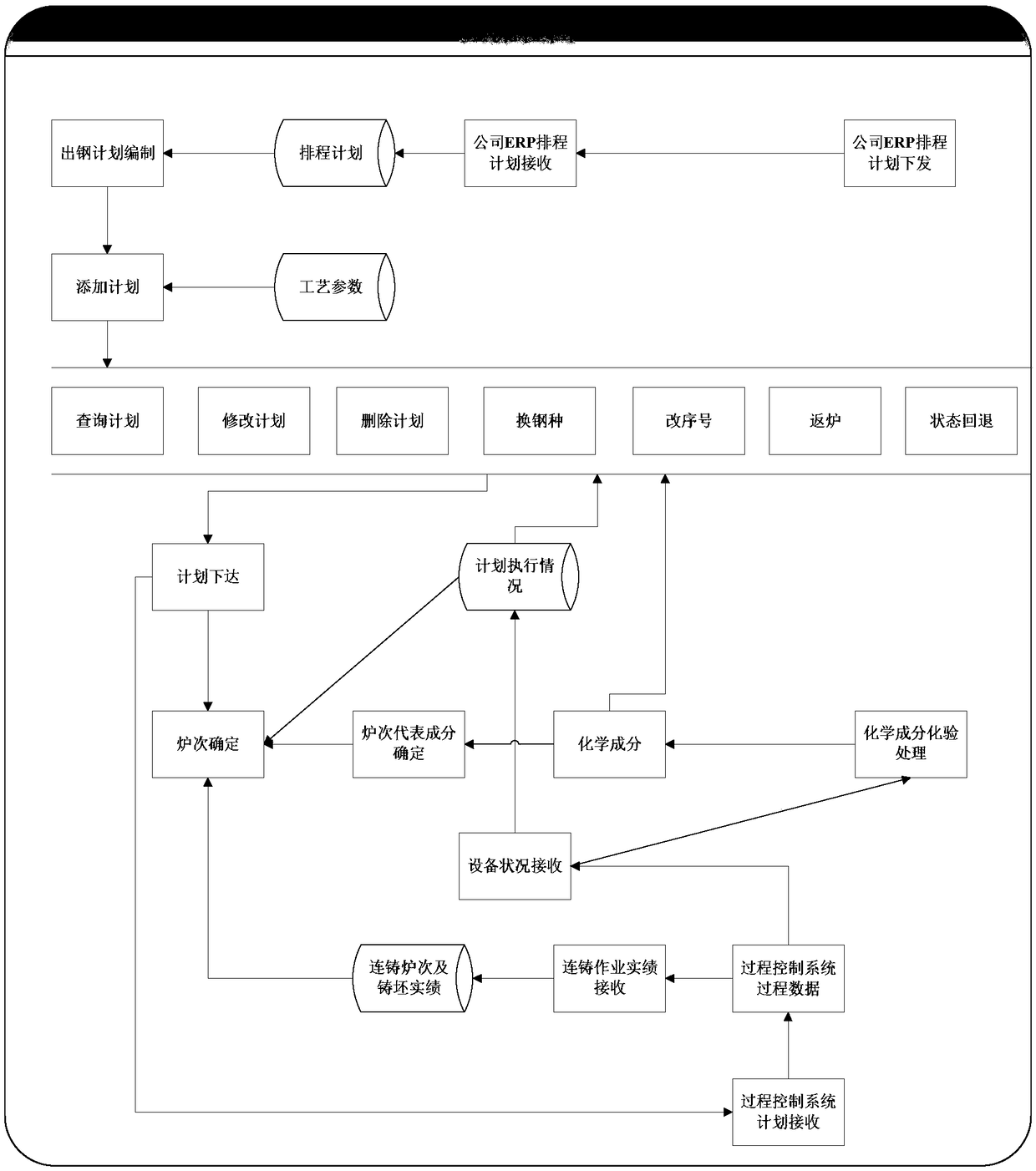

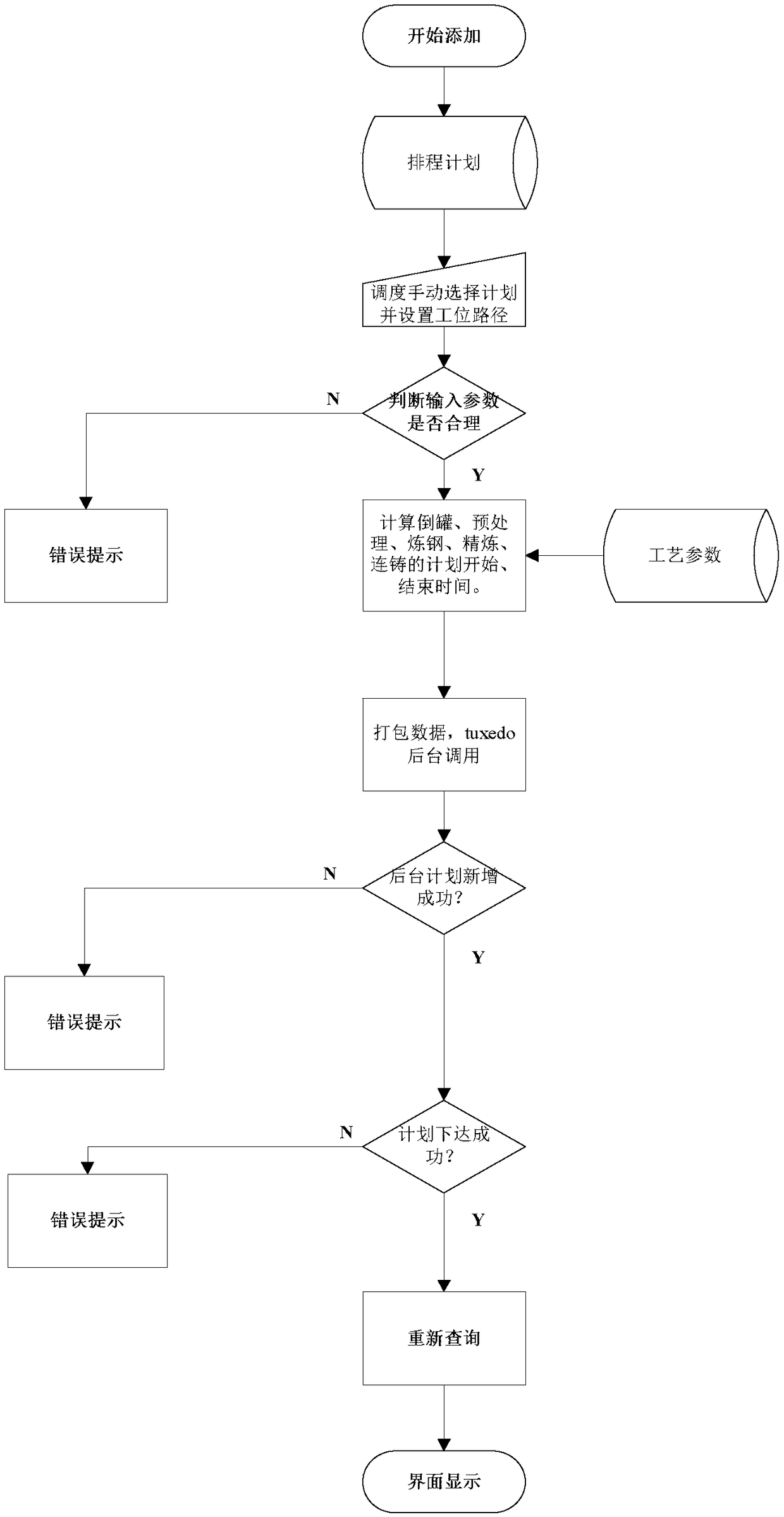

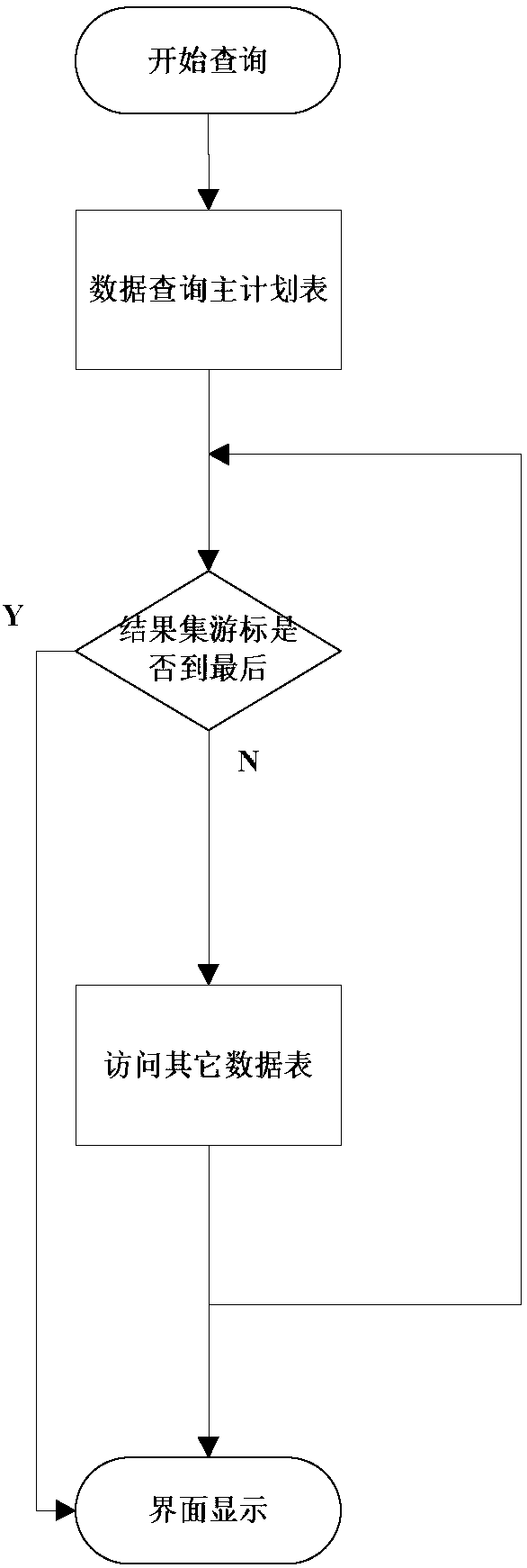

[0058] Such as figure 1 As shown, a kind of three-level production planning system of a steelmaking enterprise of the present invention comprises the following steps:

[0059] Use the manufacturing execution system to establish a three-level production planning system, including scheduling planning module, tapping plan preparation module, adding plan module, screen display module, plan issuing module, heat determination module and process control system plan receiving module;

[0060] In the above-mentioned three-level production planning system, the scheduling planning module receives the enterprise ERP scheduling plan;

[0061] In the steel tapping plan preparation module, the steel tapping plan is compiled by the dispatcher, and is processed by adding the plan module to the screen display module;

[0062] After the processing is completed, the dispatcher will assign the production task to the determined production plan, and the production plan will be received by the proce...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap