Power battery composite thermal management system and method based on natural circulation

A thermal management system, power battery technology, applied in the direction of secondary batteries, circuits, electrical components, etc., to achieve good safety performance, wide application prospects, improve power performance and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with specific embodiments.

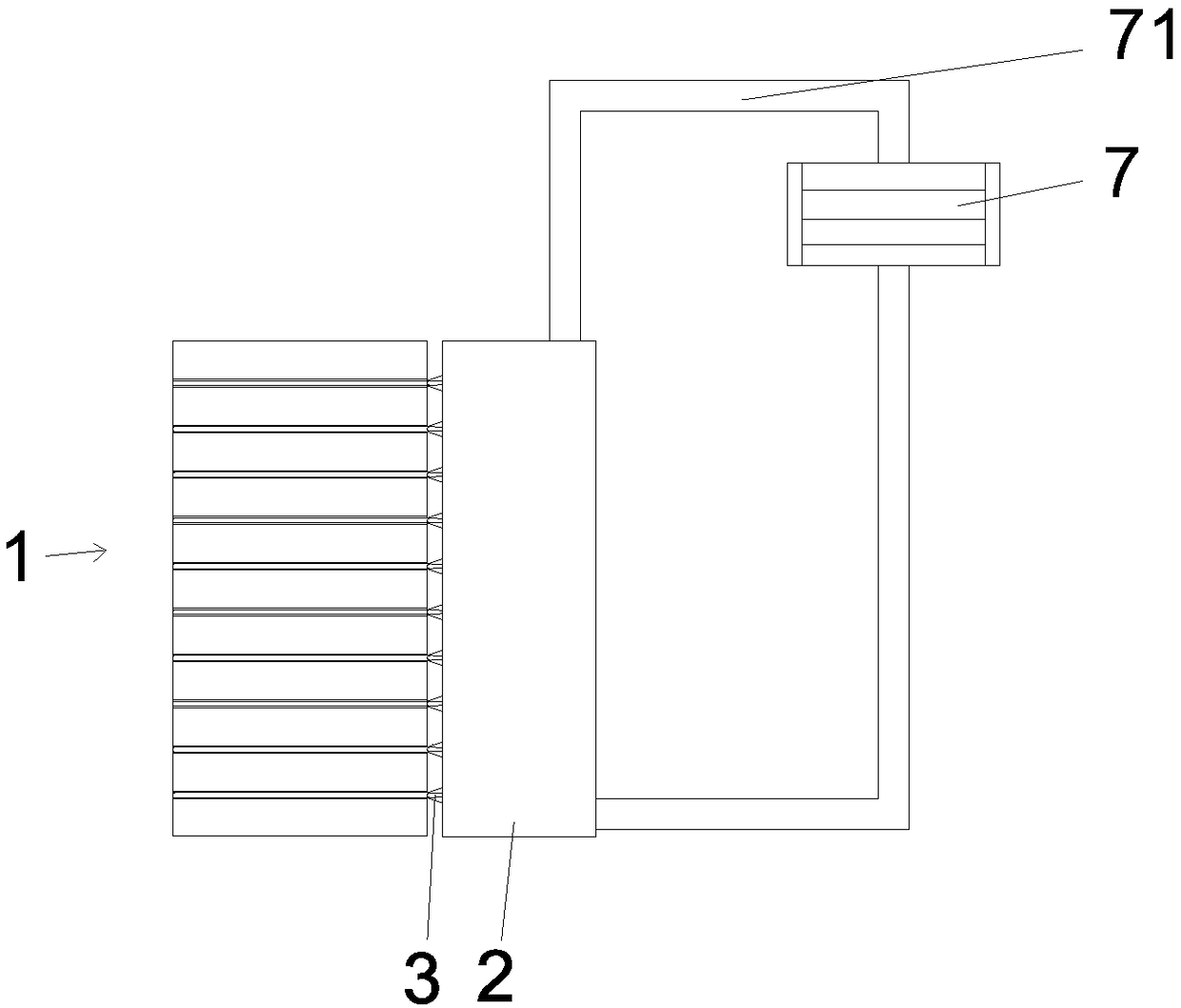

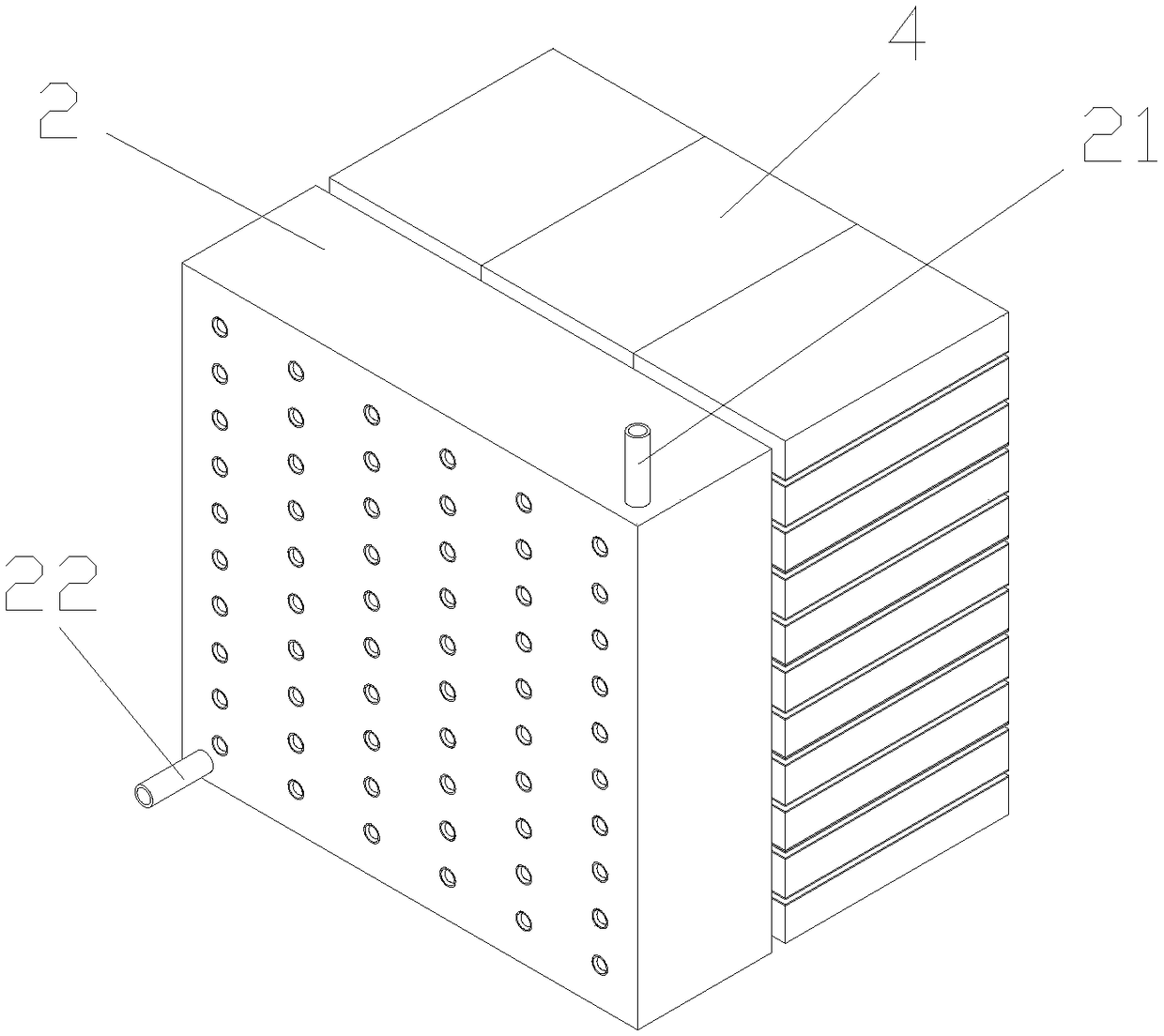

[0033] Such as Figure 1-5 shown. The invention discloses a power battery composite heat management system based on natural circulation, which includes a battery pack array 1, a cooling cavity shell 2, a condenser 7, and a heat pipe array composed of a plurality of heat pipes 3; the heat pipe 3 is a sintered heat pipe .

[0034] The battery pack array 1 is composed of a plurality of single cells 4;

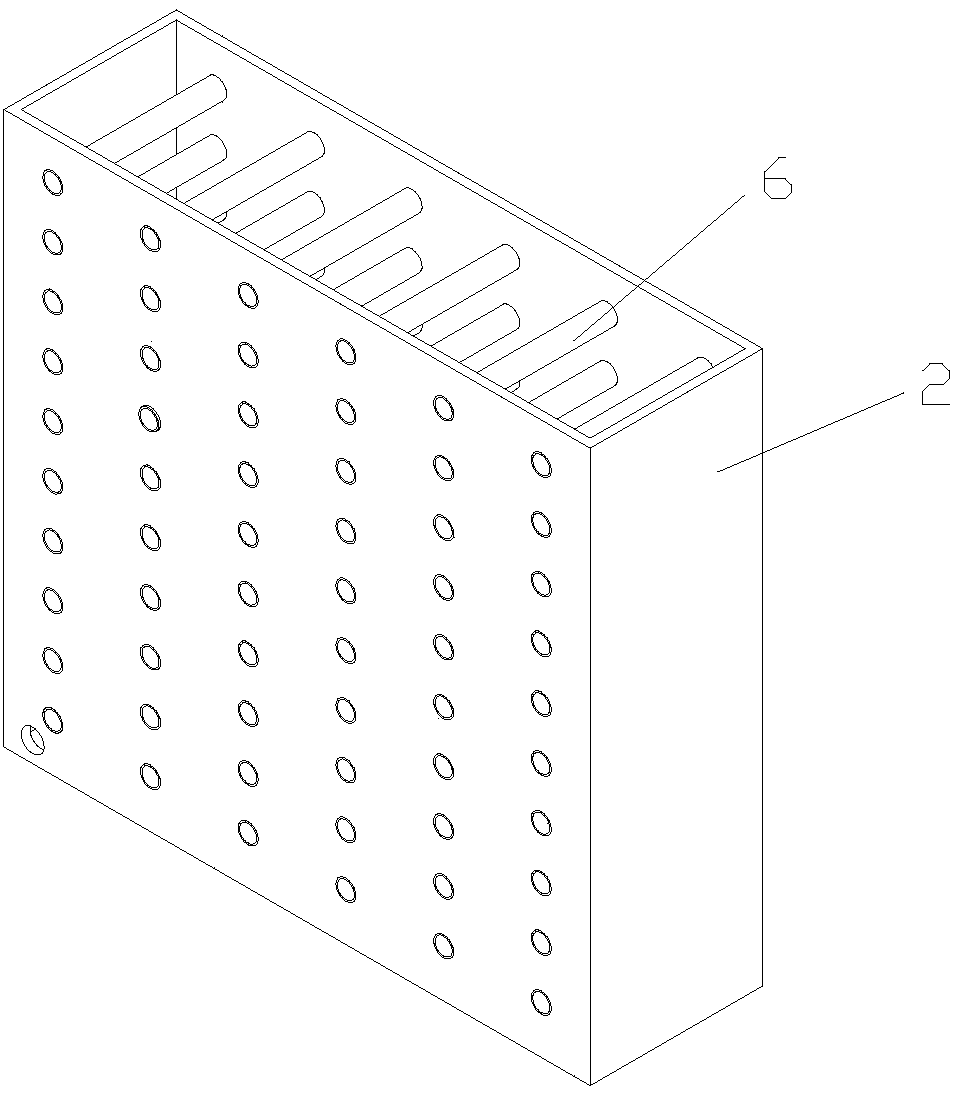

[0035] The section of the evaporation section 31 of each heat pipe 3 is flat, and the section of the condensation section 33 is circular;

[0036] The inner cavity of the cooling chamber housing 2 is distributed in a horizontal array with multiple rows of sleeves 6 that are not connected to each other; The cavity shell 2 is sealed and connected; the inner cavity of the cooling cavity shell 2 is filled with working fluid, and the casing 6 is submerged under the liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com