Power output control method for electric bicycle

A technology of power output control and electric bicycles, which is applied to vehicle components, rider driving, transportation and packaging, etc., which can solve the problems of rider inconvenience, failure to provide rider assistance, failure to serve riders, etc. Achieve good riding experience, good riding experience, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

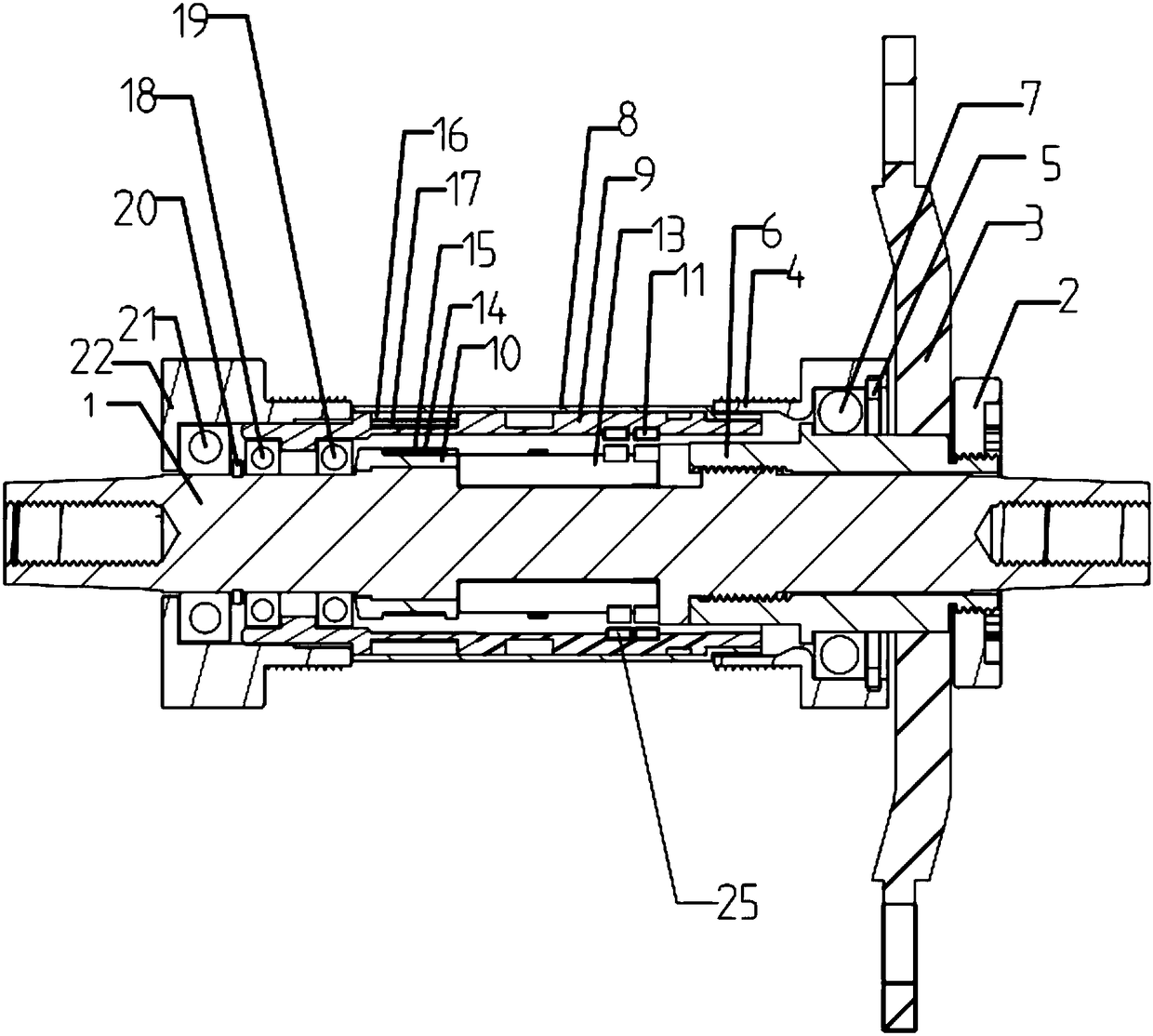

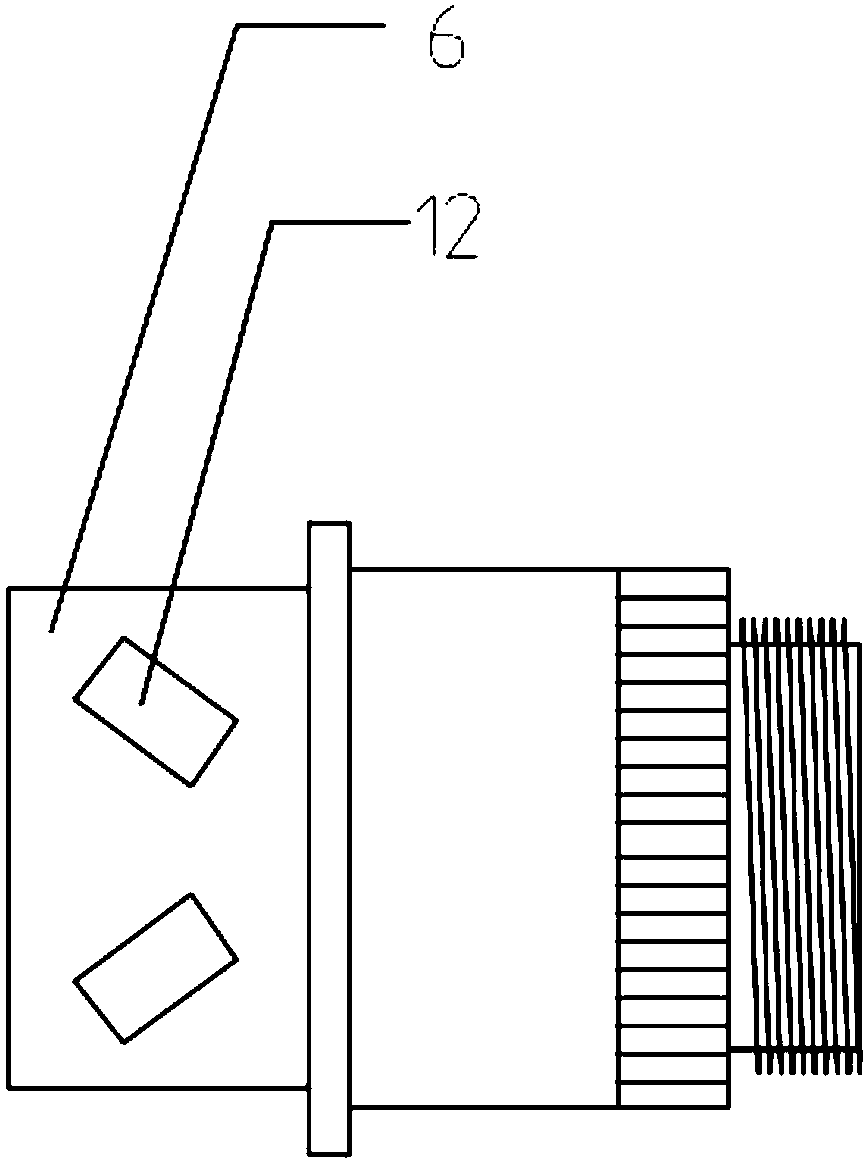

[0053] Embodiment 1 is basically as attached figure 1 As shown: the central shaft 1 torque detection system includes a lock nut 2, a claw 3, a left headset 22, a right headset 4, a central shaft 1, a deformation bridge 6, a sleeve and a magnetic isolation sleeve 10.

[0054] Such as figure 1 As shown in and , the left end and the right end of the central axis 1 are respectively connected to the left crank of the left pedal and the right crank of the right pedal by fastening screws, the left crank is located on the left side of the left headset 22, and the right crank is located on the right headset 4 to the right. An external thread is formed on the outer surface of the central axis 1 at the position connected to the deformation bridge 6 . The deformable bridge 6 is sleeved on the central shaft 1, and the deformable bridge 6 and the central shaft 1 are connected by reverse threads, and the threaded part of the central shaft 1 is locked with the internal thread of the deforma...

Embodiment 2

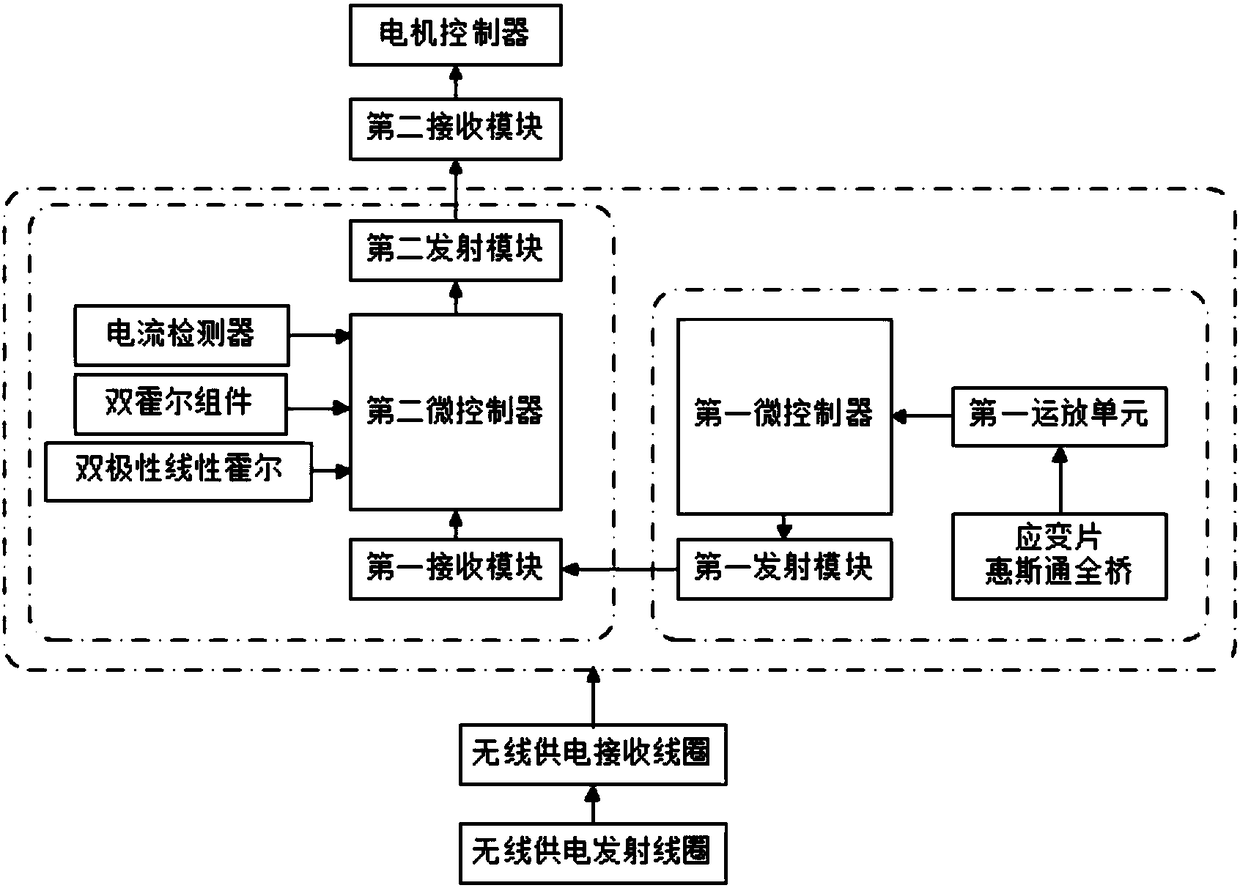

[0108] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the double Hall assembly and the bipolar linear Hall 26 are connected in the torque acquisition circuit, and the first micro-controller obtains the characteristic pedaling frequency and the centering frequency from the double Hall assembly. For the electrical signal of the rotation direction of the shaft 1, the first microcontroller obtains the electrical signal representing the crank rotation angle from the bipolar linear Hall 26, and transmits these electrical signals to the torque processing control circuit. At this time, the two circuits can be arranged together on the central axis 1 or separately, the torque acquisition circuit is arranged on the central axis 1 and the torque processing control circuit is arranged on the mounting sleeve 9 . When the torque acquisition circuit and the torque processing control circuit are set separately, the first transmitting module and the ...

Embodiment 3

[0110] Such as Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the double Hall assembly and the strain gauge 12 units are connected in the torque acquisition circuit, and the first micro-controller obtains the characteristic pedaling frequency and the rotation of the central shaft 1 from the double Hall assembly. As for the electrical signal of the direction, the bipolar linear Hall 26 is connected in the torque processing control circuit, and the second micro-controller obtains an electrical signal representing the rotation angle of the crank from the bipolar linear Hall 26. At this time, the two circuits can be arranged together on the central axis 1 or separately, the torque acquisition circuit is arranged on the central axis 1 and the torque processing control circuit is arranged on the mounting sleeve 9 . When the torque acquisition circuit and the torque processing control circuit are set separately, the first transmitting module and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com