Packing machine raw material conveying device for rectangular boxes

A raw material conveying and packaging machine technology, applied in packaging and other directions, can solve the problems of high labor intensity and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

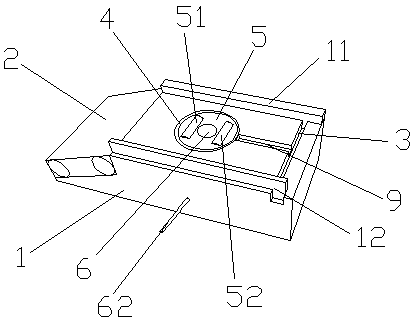

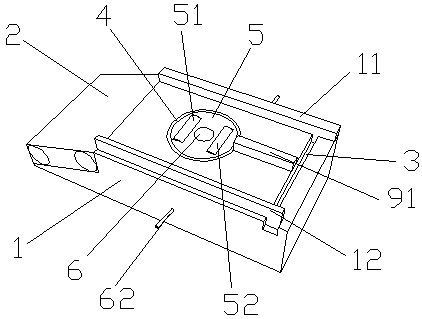

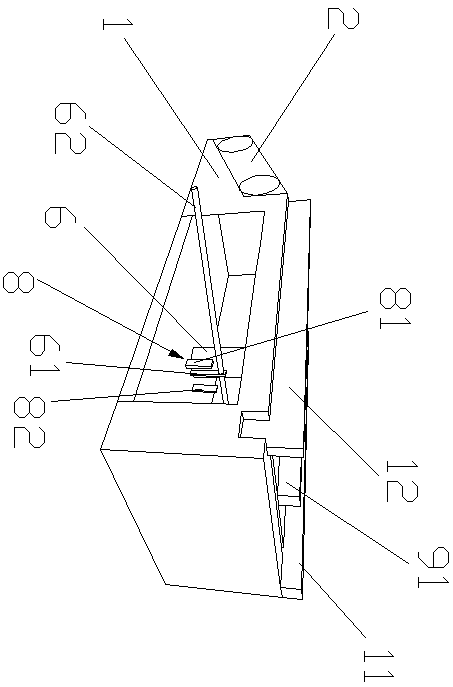

[0024] Such as Figure 1-5 As shown, a raw material conveying device for a packaging machine for rectangular boxes of the present invention includes a conveying rack 1. The conveying rack 1 is a hollow structure. One end of the conveying rack 1 is provided with a conveyor belt 2 obliquely, and the top surface of the conveying rack 1 is provided with Stop rod groove 3, one end of the stop rod groove 3 is fixedly provided with a first stop rod 11, the other end of the stop rod groove 3 is movably provided with a second stop rod 12, and the first stop rod 11 and the second stop rod 12 Are parallel to each other, the top surface of the conveying rack 1 is also provided with a turntable slot 4, the turntable 5 is movably arranged in the turntable slot 4, and a rotating shaft 6 is also arranged in the conveying rack 1, and one end of the rotating shaft 6 is fixedly connected with the turntable 5. The other end of 6 is movably arranged on the bottom surface of the conveying rack 1, an...

Embodiment 2

[0026] The conveying rack 1 has a hollow structure. One end of the conveying rack 1 is provided with a conveyor belt 2 obliquely, a stop bar groove 3 is provided on the top surface of the conveying rack 1, and one end of the stop bar groove 3 is fixedly provided with a first stop bar 11, the stop bar A second stop rod 12 is movably arranged in the other end of the groove 3, and the first stop rod 11 and the second stop rod 12 are parallel to each other. The top surface of the conveying rack 1 is also provided with a turntable slot 4, and the turntable slot 4 A turntable 5 is movably provided, and a rotating shaft 6 is also arranged in the conveying rack 1, and one end of the rotating shaft 6 is fixedly connected with the rotating disk 5, the other end of the rotating shaft 6 is movably arranged on the bottom surface of the conveying rack 1, and the other end of the rotating shaft 6 is also provided There is an adjusting rod seat 61, an adjusting rod 62 is fixed on the adjusting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com