Sterile shield of sterile medical instrument

A sterile barrier and medical device technology, applied in the field of medical devices, can solve problems such as easy breakage, avoid re-use, reduce the risk of breakage, and improve safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

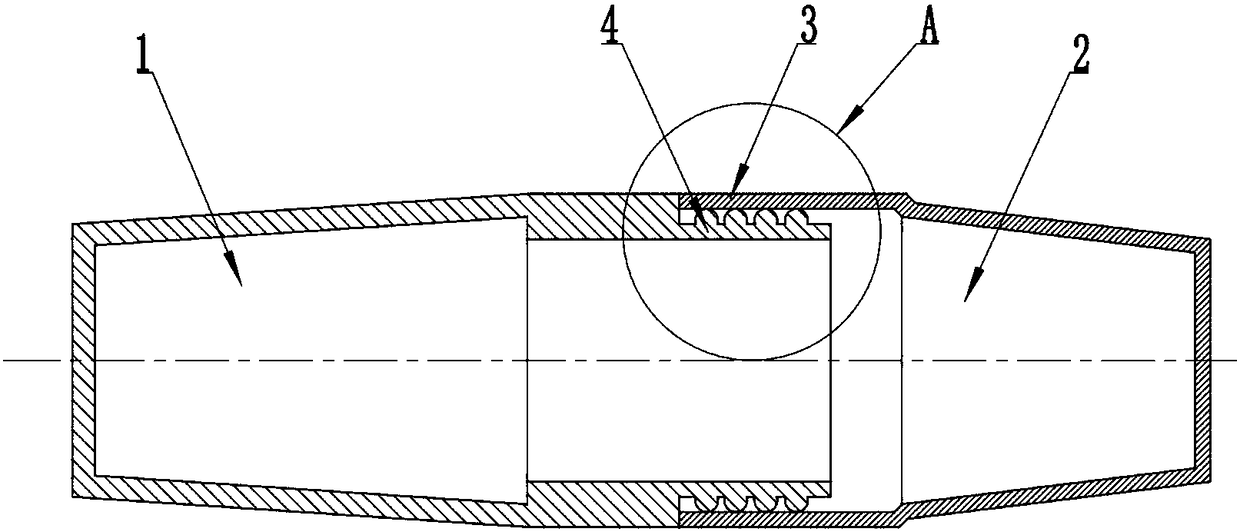

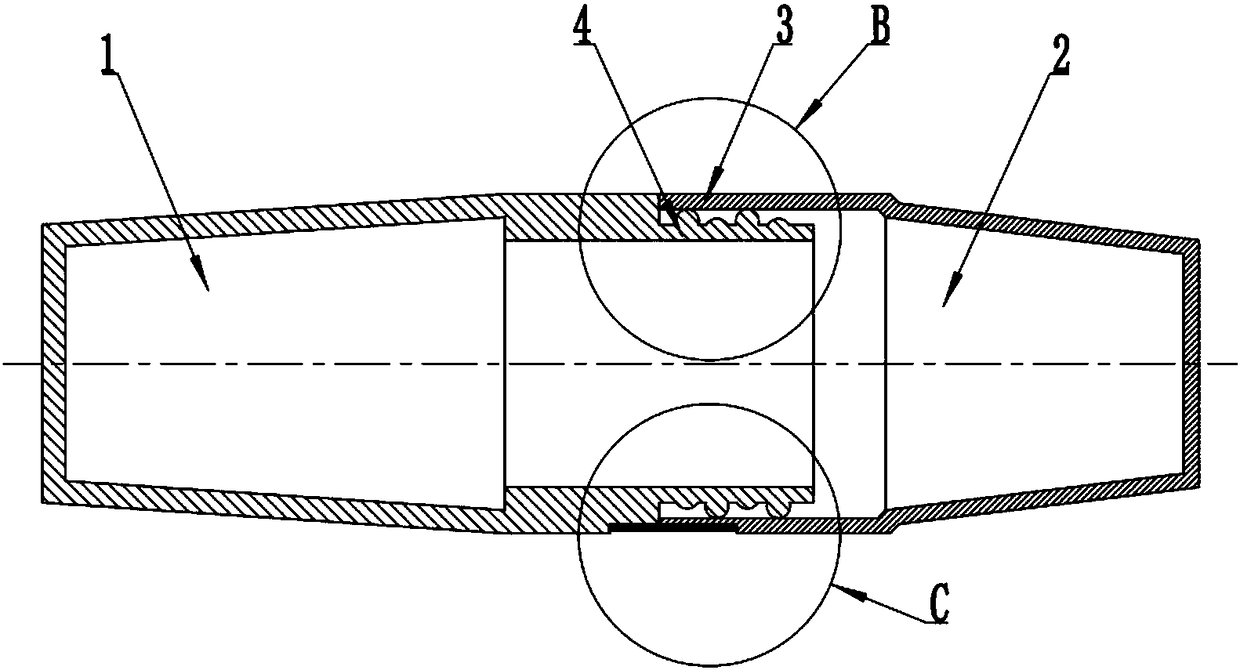

[0027] like figure 1 , figure 2 As shown, the aseptic barrier of the sterile medical device includes a left casing 1 and a right casing 2, one end of the left casing 1 is sealed, and the other end of the left casing 1 is provided with a cylindrical inner socket 4, and the right casing One end of the body 2 is provided with an outer socket 3 matched with the inner socket 4, the other end of the right housing 2 is sealed, a sealing convex ring 5 is provided between the inner socket 4 and the outer socket 3, and the inner socket 4 and the outer socket 3 are sealed. The outer seam 8 between them is provided with a melt line 9 .

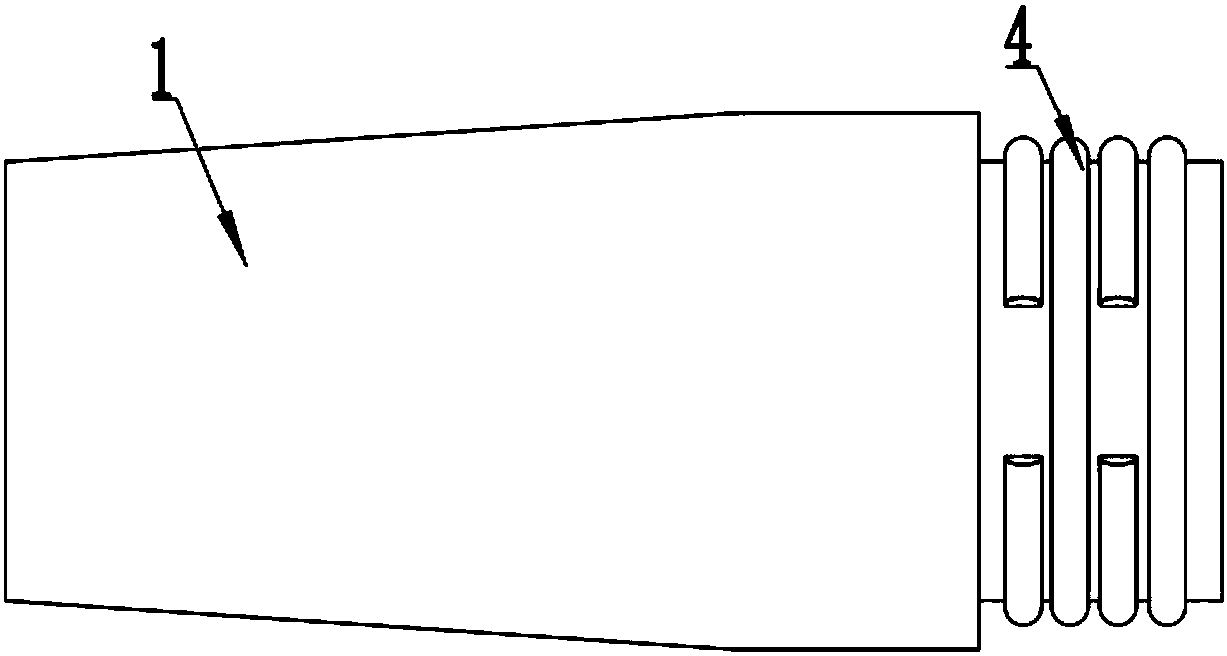

[0028] like image 3 , Figure 4 , Figure 5 As shown, a plurality of sealing protruding rings 5 can be evenly distributed on the outer wall of the inner socket 4, and each sealing protruding ring 5 is provided with a gap 7, and the gaps 7 on two adjacent sealing protruding rings 5 are staggered. Setting, the interference fit between the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com