Measuring method for fracture toughness of bubbling interface of bridge deck pavement layer

A bridge deck pavement and fracture toughness technology, which is applied in the field of transportation, can solve problems such as corrosion of bridge decks, economic losses, and water damage to pavement layers, and achieve small errors in energy release rates, safety assurance, and small data errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

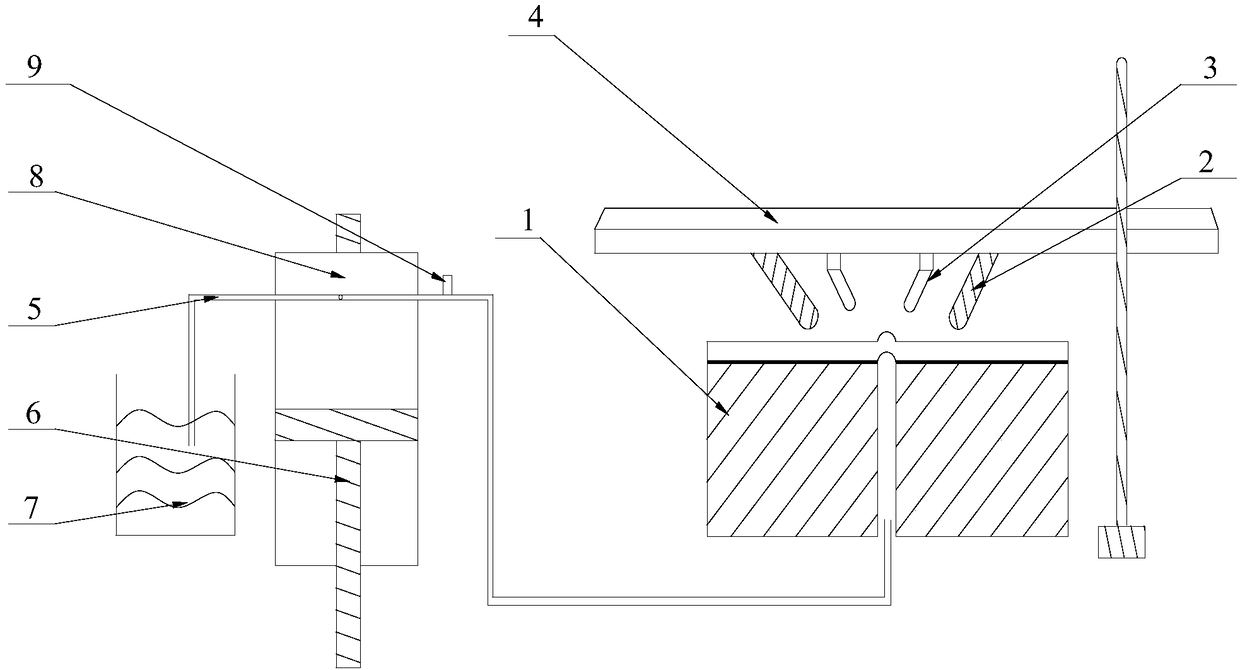

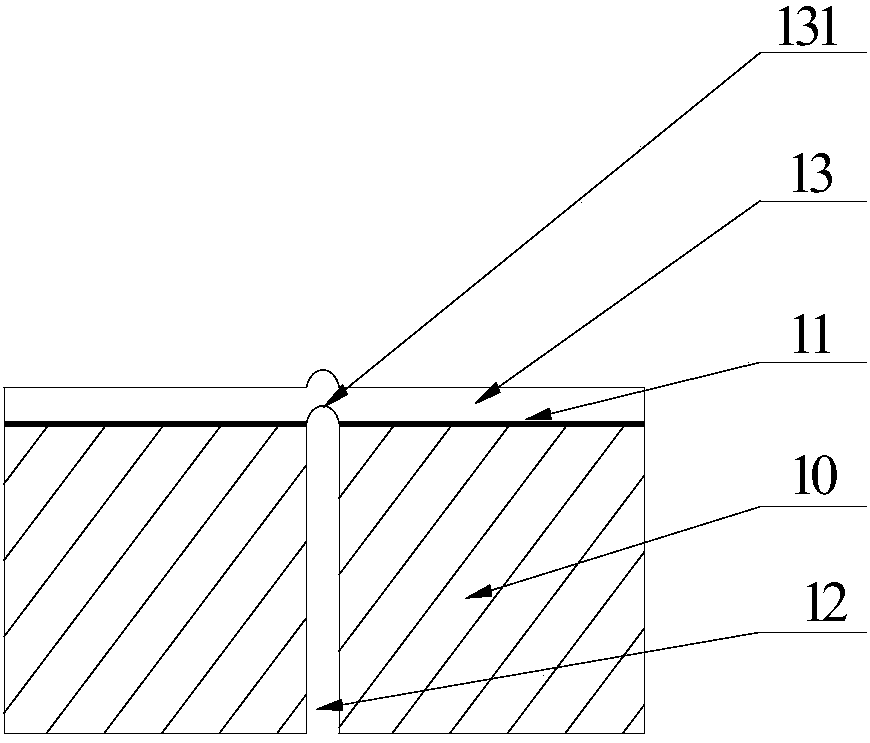

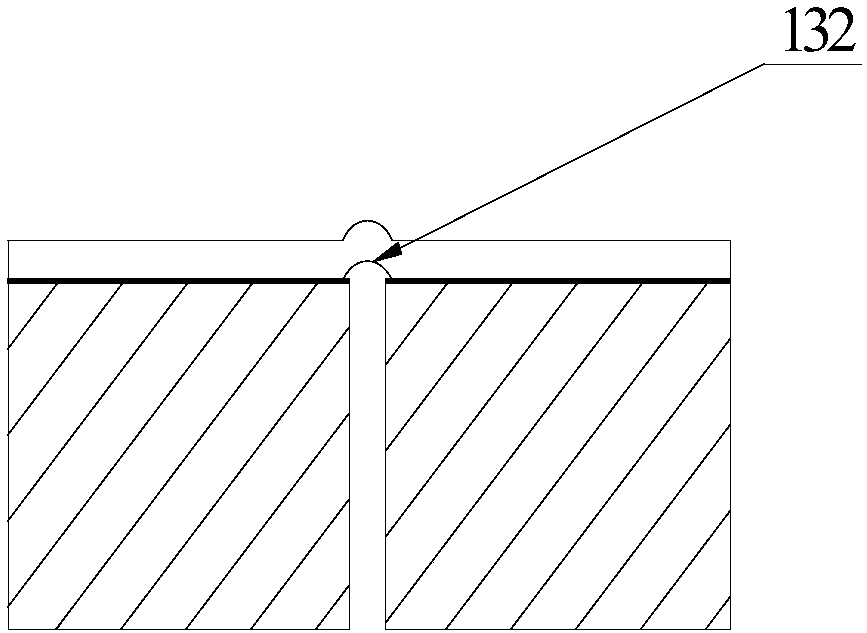

[0043] As shown in the figure: the measuring method of the bridge deck pavement bubbling interface fracture toughness in the present embodiment comprises the following steps:

[0044] (1) Take two bridge deck pavement test pieces 1 with different bubbling radii and place them on the platform. Except for the different bubbling radii of the bridge deck pavement, the other conditions of the test pieces are the same;

[0045] (2) Continuously apply uniform loads to the two bridge deck pavement layers 13 with different bubbling radii until the critical expansion of the bridge deck pavement layer 13 bubbling 131. In this embodiment, a single limit loading method is adopted, for Make the deformation of the bridge deck pavement specimen 1 increase at a constant speed, and keep a loading speed of 10mm / min for uniform loading. In order to avoid the impact effect from affecting the test results, try to maintain a constant loading speed until the bridge deck pavement specimen 1. Until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com