Electrostatic discharge test system

A technology for electrostatic discharge testing and motor shafts, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problem of low test accuracy, achieve the effects of improving test accuracy, obvious energy saving effect, and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

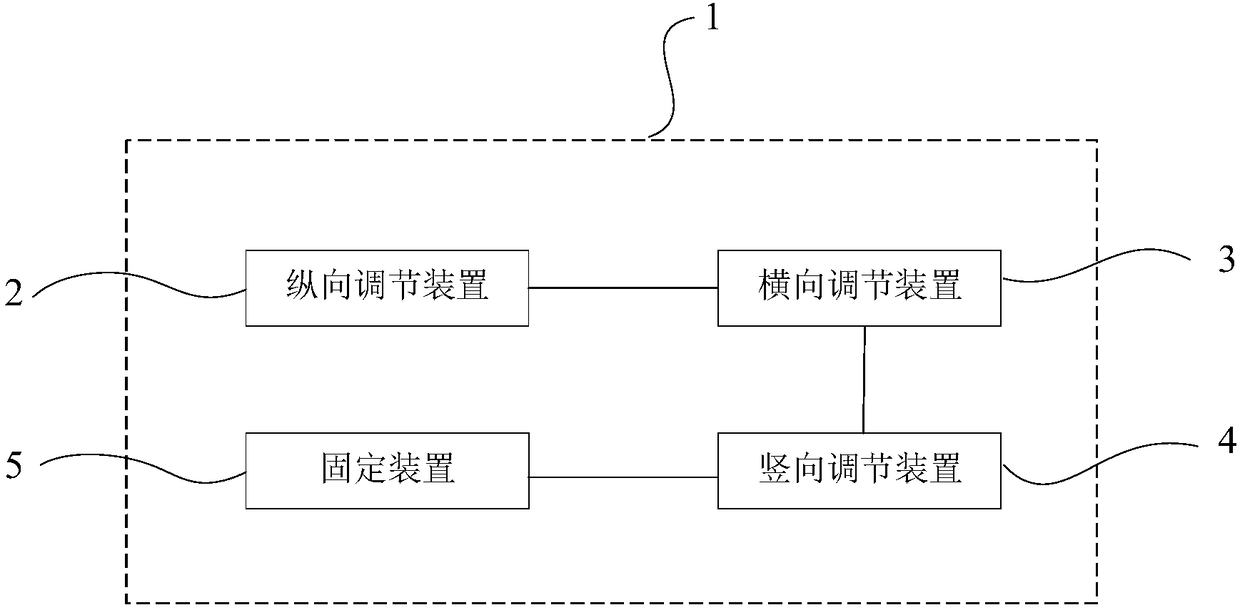

[0097] like figure 1 As shown, the electrostatic discharge testing system 1 includes a longitudinal adjustment device 2 , a horizontal adjustment device 3 , a vertical adjustment device 4 and a fixing device 5 . The fixing device 5 is used for installing an electrostatic gun (not shown in the figure). The longitudinal adjusting device 2 is used to drive the fixing device 5 to move longitudinally in the horizontal direction. The lateral adjusting device 3 is used to drive the fixing device 5 to move laterally in the horizontal direction. The vertical adjusting device 4 is used to drive the fixing device 5 to move vertically. In this embodiment, the longitudinal adjustment device 2 , the horizontal adjustment device 3 , the vertical adjustment device 4 and the fixing device 5 are connected in sequence. The electrostatic discharge testing system 1 is used for testing the antistatic ability of mobile terminals (such as mobile phones, tablet computers, etc.).

[0098] like fi...

Embodiment 2

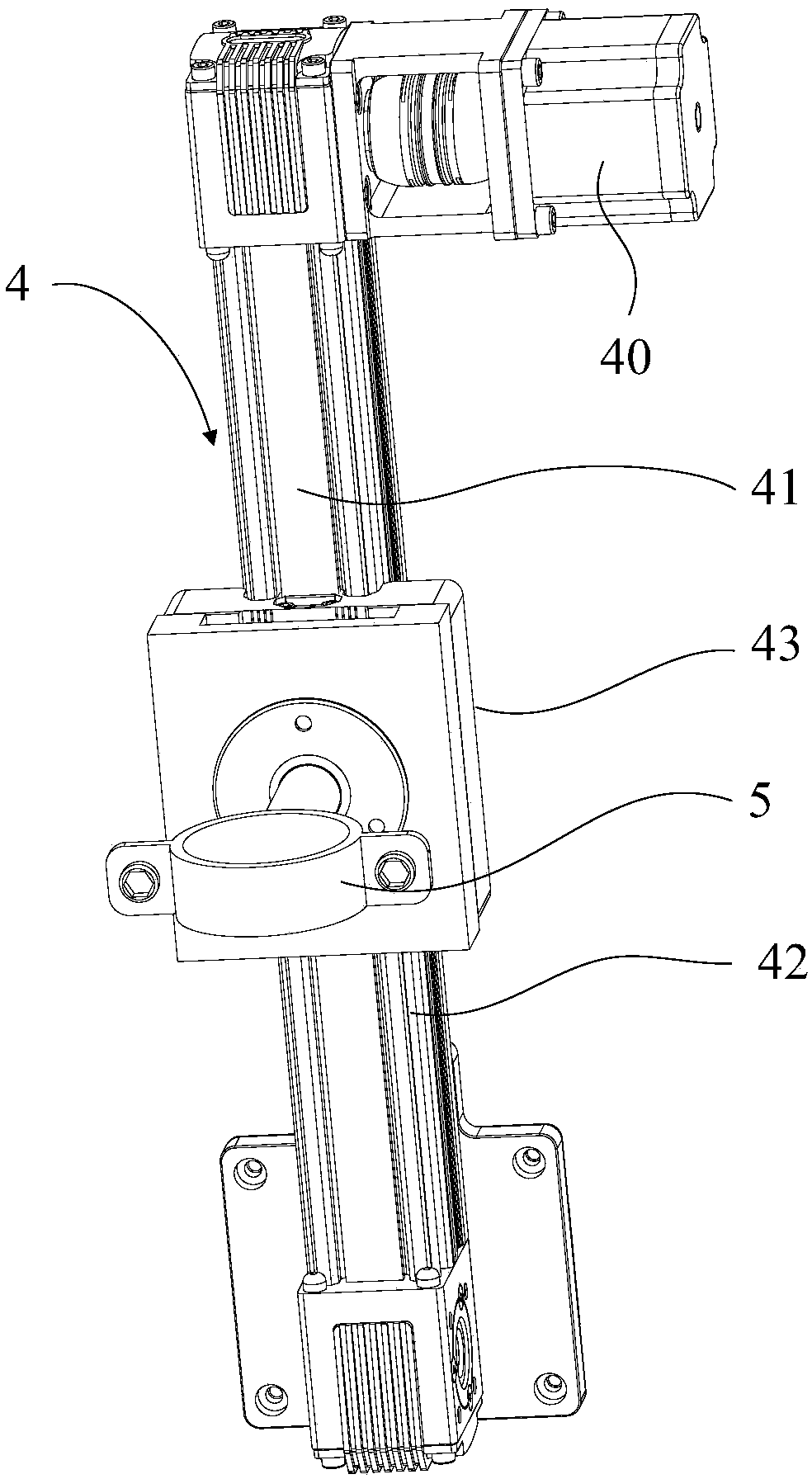

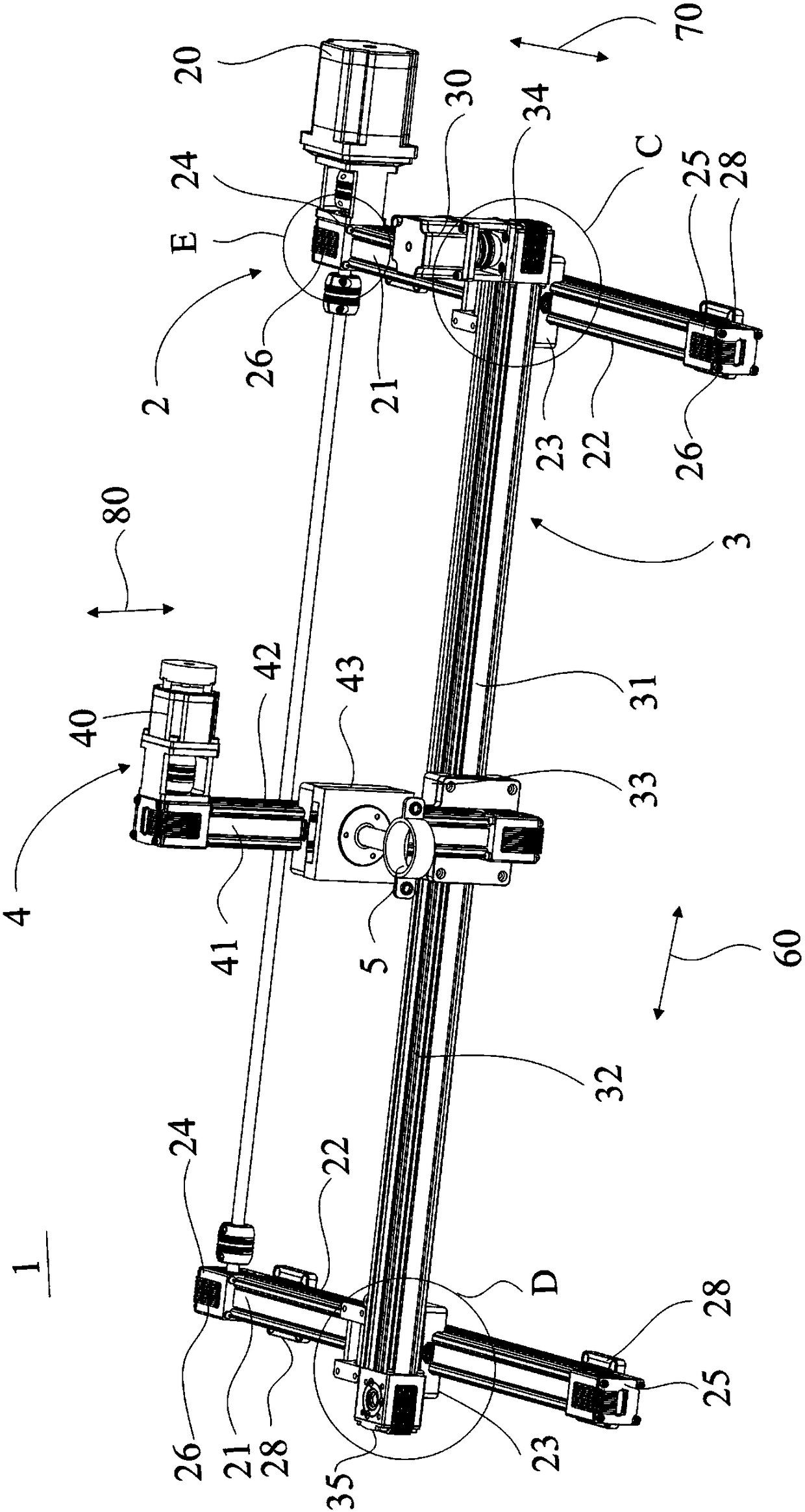

[0103] like image 3 As shown, the electrostatic discharge testing system 1 includes a longitudinal adjustment device 2 , a horizontal adjustment device 3 , a vertical adjustment device 4 and a fixing device 5 . The fixing device 5 is used to install the electrostatic gun. The longitudinal adjusting device 2 is used to drive the fixing device 5 to move along the longitudinal direction 70 in the horizontal direction. The lateral adjusting device 3 is used to drive the fixing device 5 to move horizontally along the lateral direction 60 . The vertical adjusting device 4 is used to drive the fixing device 5 to move along the vertical direction 80 . In this embodiment, the longitudinal adjustment device 2 , the horizontal adjustment device 3 , the vertical adjustment device 4 and the fixing device 5 are connected in sequence. The electrostatic discharge testing system 1 is used for testing the antistatic ability of mobile terminals (such as mobile phones, tablet computers, etc.)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com