Malt wort bread and preparation method thereof

A technology for wort and wort aroma, which is applied in the direction of dough processing, baking, and baked goods with modified ingredients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

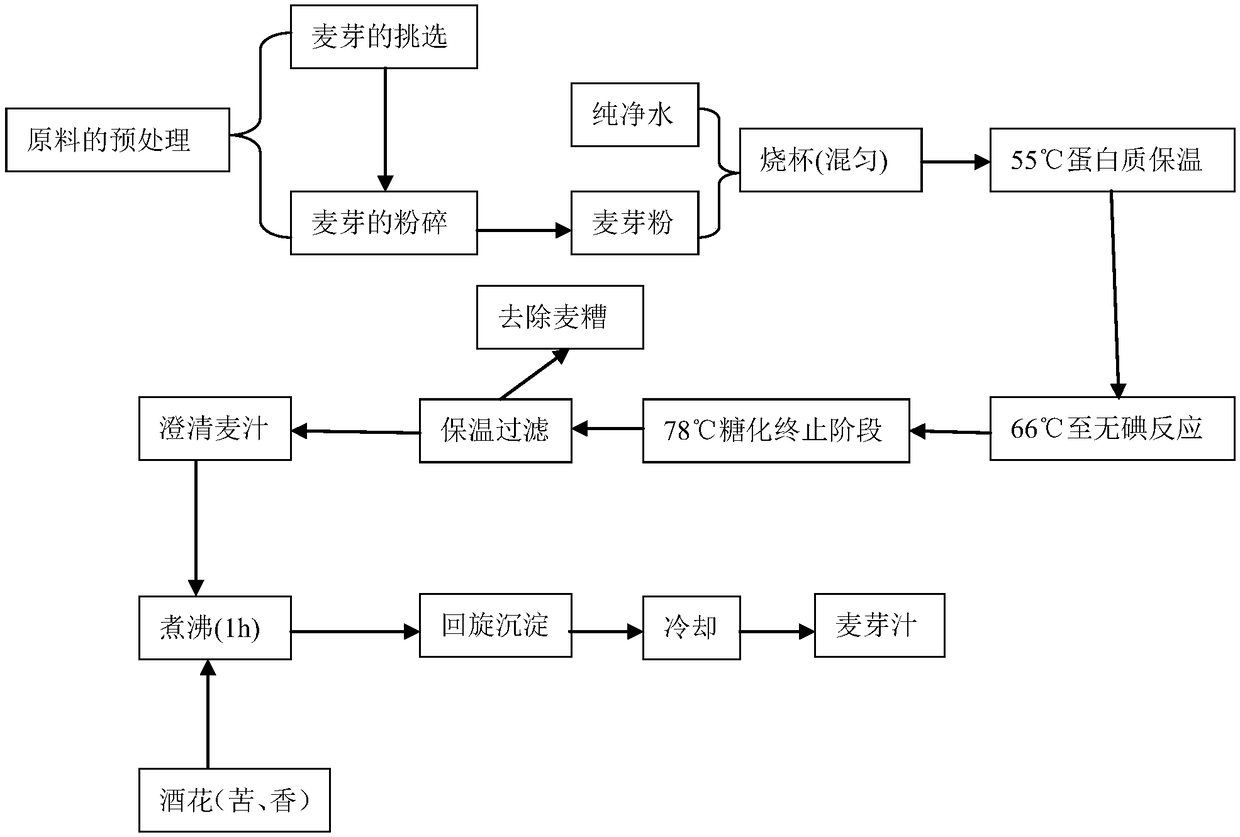

[0018] A preparation method for preparing wort-flavored bread from wort obtained from hops comprises the following steps:

[0019] (1) Selection and crushing of malt: calculate the required malt mass, and weigh the required mass of barley malt and caramel malt.

[0020] (2) Protein insulation at 55°C: Weigh the malt powder in step (1) into a beaker, add an appropriate amount of water, stir evenly with a glass rod, and heat at 55°C for 30 minutes.

[0021] (3) Carry out saccharification reaction at 66°C: place the mixed solution in step (2) in a constant temperature water bath at 66°C to carry out saccharification reaction, which takes about 1.5-2 hours.

[0022] (4) Termination of saccharification at 78°C: the temperature of the water bath was increased to 78°C, and after the temperature of the mixture of malt powder and water in step (3) reached 78°C, the reaction was stopped by timing for 10 minutes.

[0023] (5) Filtration and boiling: After filtering the mixed solution in...

Embodiment 1

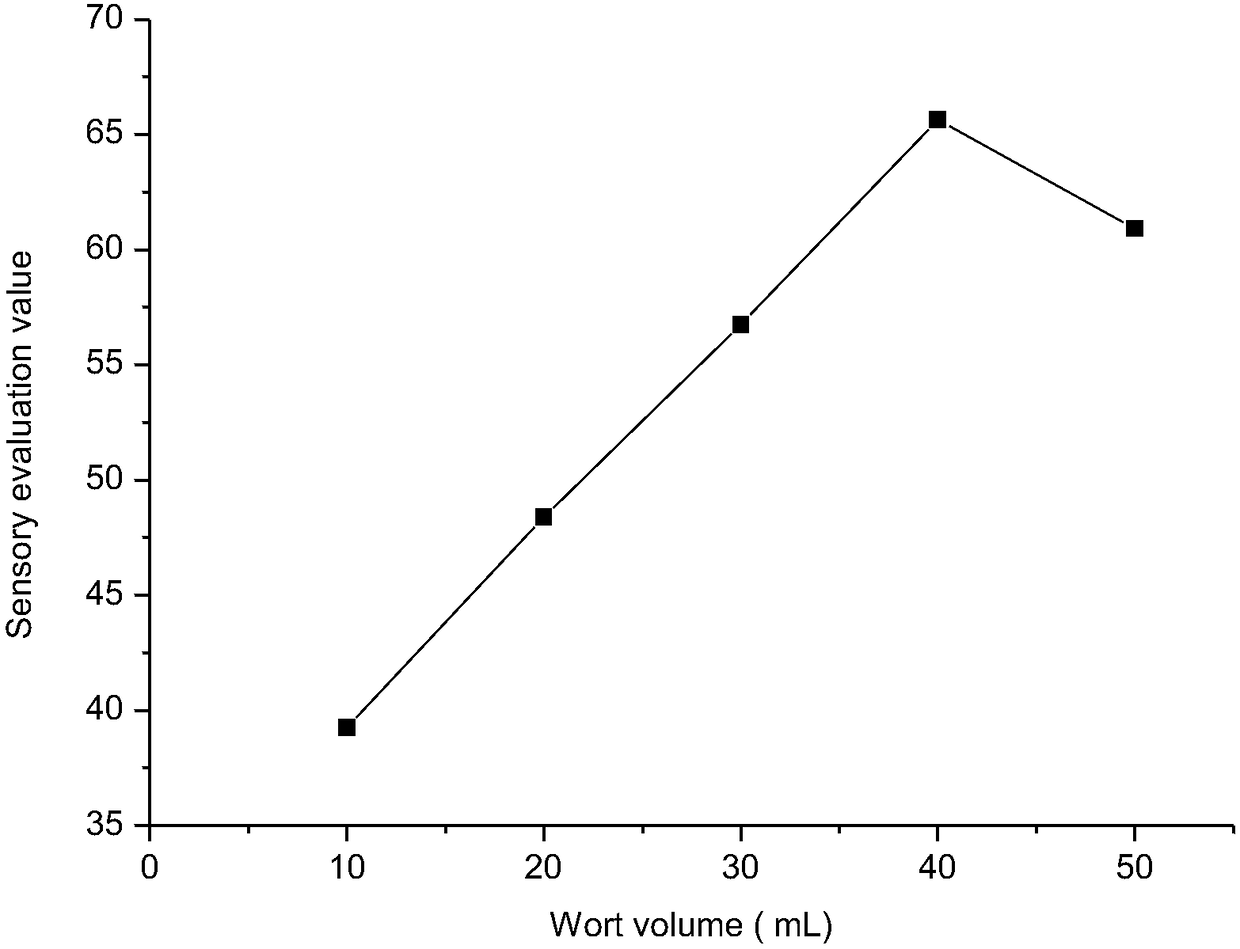

[0035] The making of bread under the different wort volumes of embodiment 1

[0036] (1) Preparation of wort: Weigh malt powder into a beaker, add appropriate amount of water, stir evenly with a glass rod and keep warm at 55°C for 30 minutes, and place the mixed solution in a constant temperature water bath at 66°C for saccharification reaction. After 1.5-2 hours, the temperature of the water bath was increased to 78°C, and after the temperature of the mixture reached 78°C, the reaction was stopped by timing for 10 minutes. After filtering the mixed solution, boil it for a total of 1 hour. During this time, add bitter flowers and fragrant flowers in stages. After boiling, the mixed solution is whirled and cooled to obtain clarified wort.

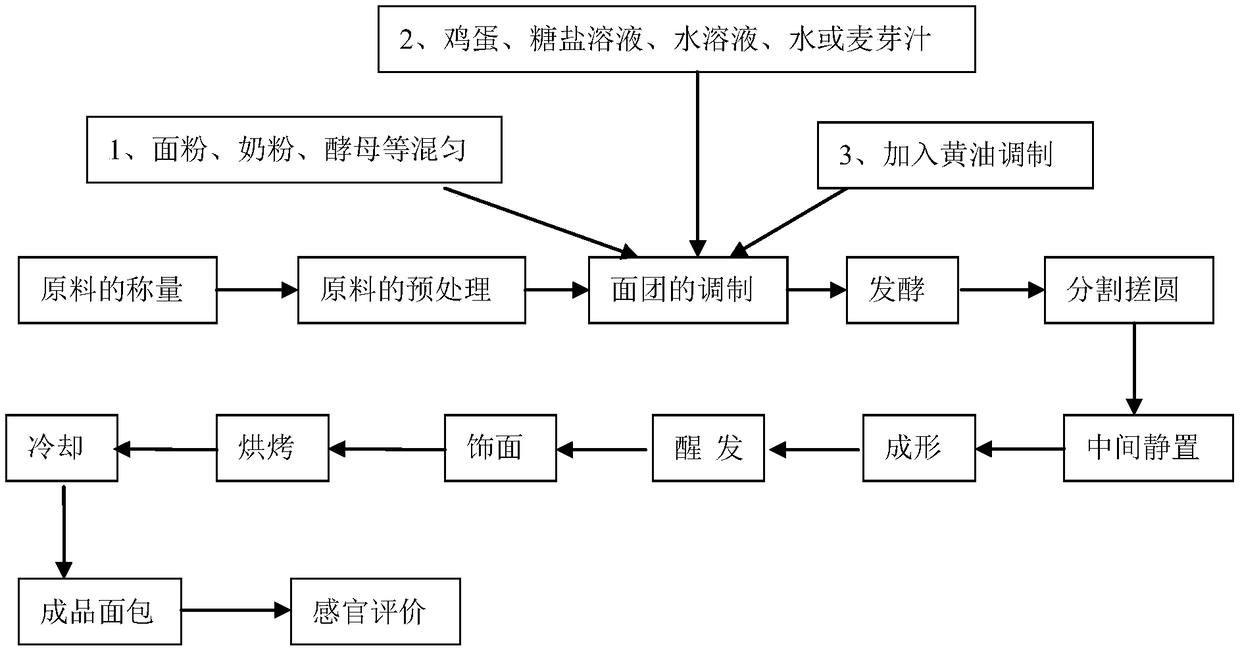

[0037] (2) Dough production process: Weigh the required raw materials: 100 parts of high-gluten flour, 1.5 parts of yeast powder, 12 parts of sugar, 8 parts of milk powder, 1 part of salt, 12 parts of eggs, 8 parts of butter, 0.8 parts of b...

Embodiment 2

[0040] The making of embodiment 2 different fermentation time bread

[0041] (1) Preparation of wort: Weigh malt powder into a beaker, add appropriate amount of water, stir evenly with a glass rod and keep warm at 55°C for 30 minutes, and place the mixed solution in a constant temperature water bath at 66°C for saccharification reaction. After 1.5-2 hours, the temperature of the water bath was increased to 78°C, and after the temperature of the mixture reached 78°C, the reaction was stopped by timing for 10 minutes. After filtering the mixed solution, boil it for a total of 1 hour. During this time, add bitter flowers and fragrant flowers in stages. After boiling, the mixed solution is whirled and cooled to obtain clarified wort.

[0042] (2) Dough production process: Weigh the required raw materials: 100 parts of high-gluten flour, 1.5 parts of yeast powder, 12 parts of sugar, 8 parts of milk powder, 1 part of salt, 12 parts of eggs, 8 parts of butter, 0.8 parts of bread imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com