Automobile brake disc cleaning machine

A technology for automobile brakes and washing machines, applied in cleaning methods and tools, cleaning methods using liquids, cleaning methods using tools, etc., can solve the problems of insufficient friction between brake discs and brake pads, safety accidents affecting brake performance, and easy Dirty brake discs and other problems to achieve the effect of avoiding traffic accidents, fully cleaning, and improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

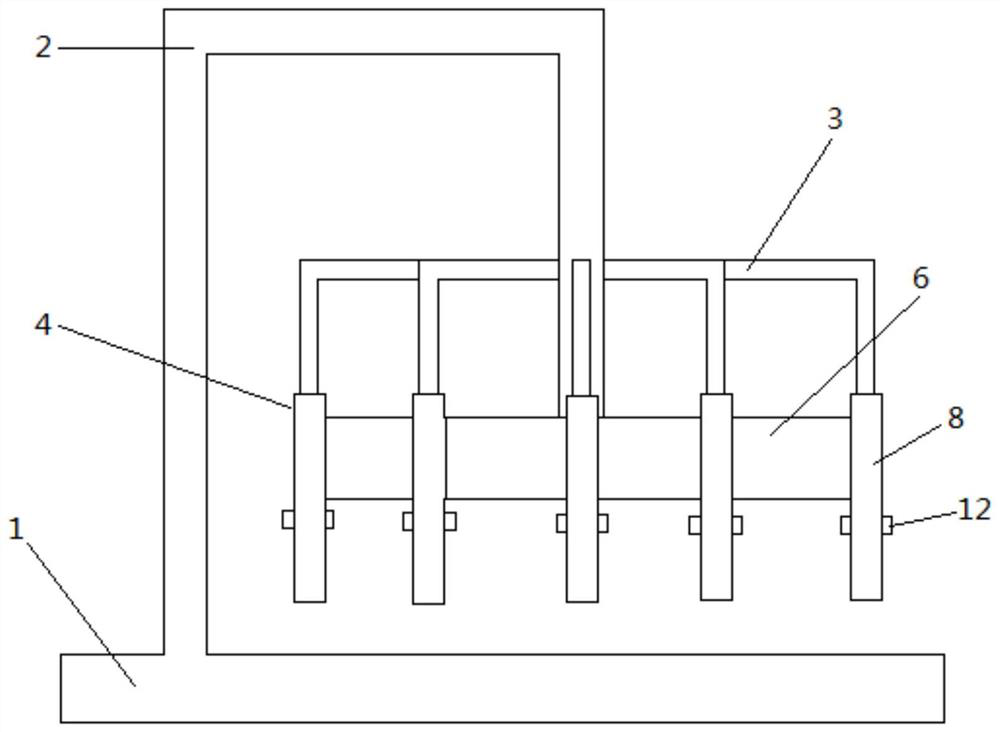

[0033] The embodiment is basically as attached figure 1 Shown: a car brake disc cleaning machine, including a cleaning table 1, a water outlet pipe 2, a cleaning part 4 and a motor. The motor is provided with a forward and reverse control switch and a one-way control switch.

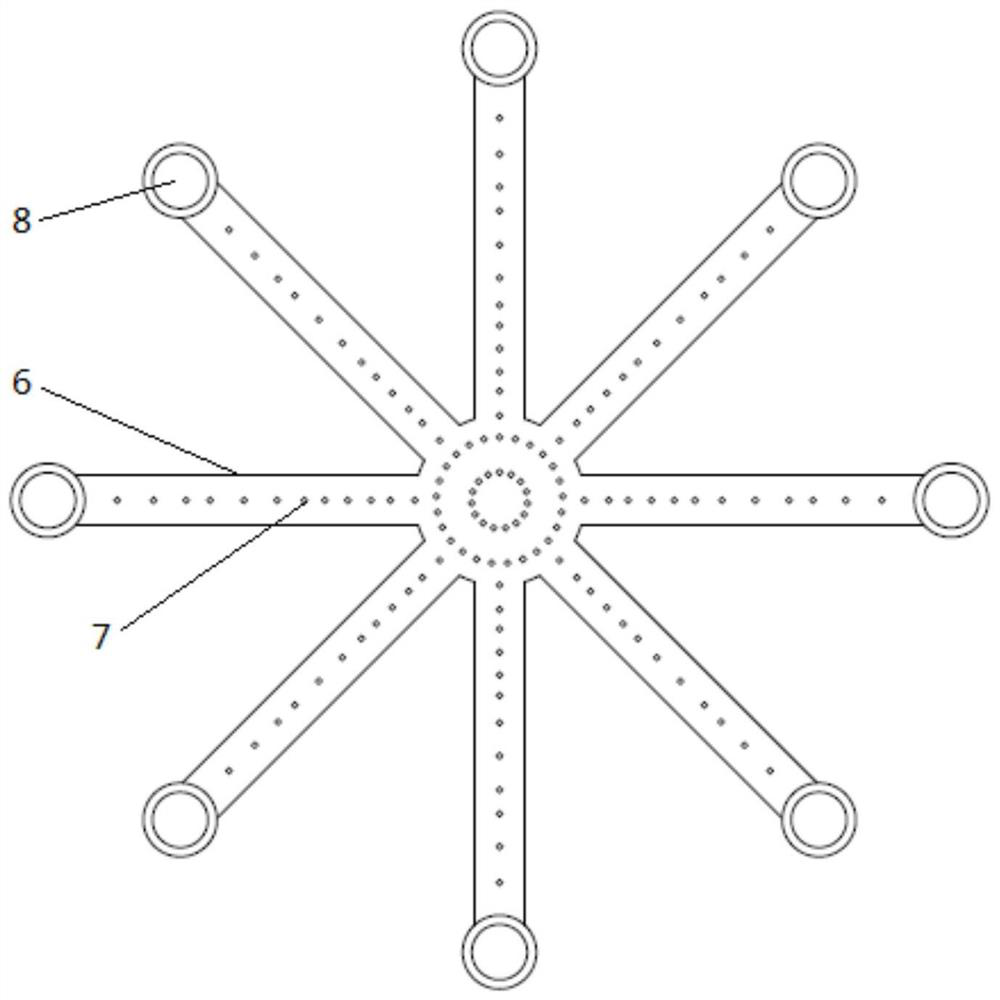

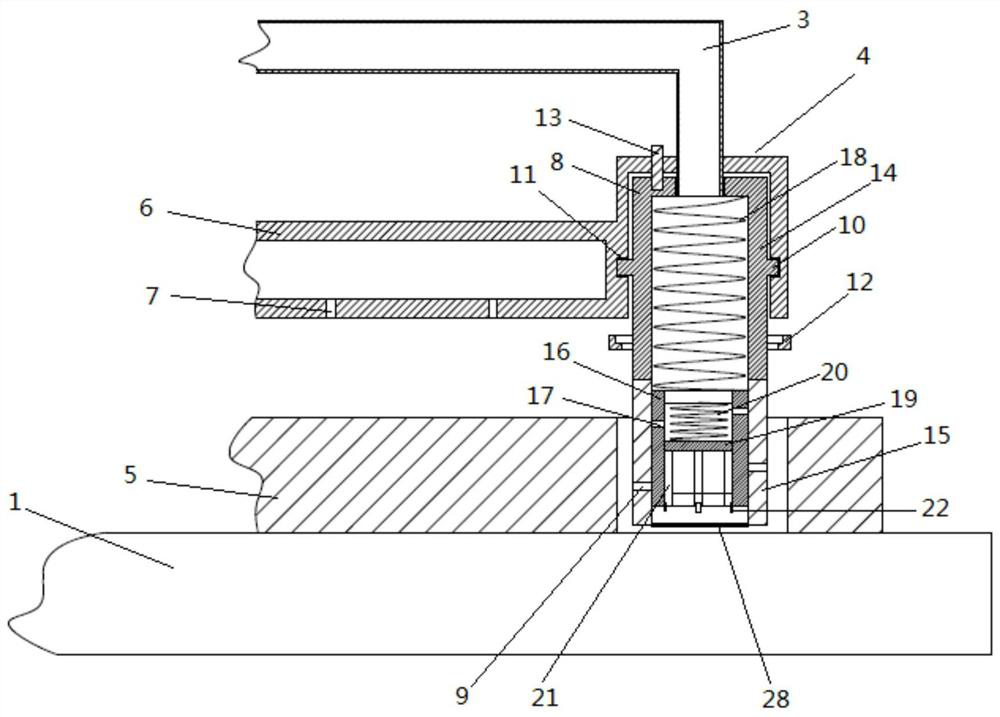

[0034] Such as figure 2 As shown, the cleaning part 4 includes several hollow brackets 6 and cleaning pipes 8 , and the middle part of the hollow brackets 6 is hingedly connected with the water outlet pipe 2 . A number of water outlet holes 7 are arranged on the lower end surface of the hollow support 6 . Such as image 3 As shown, the side wall of the cleaning pipe 8 is provided with a number of cleaning holes 9, the wall of the cleaning pipe 8 near the end of the water outlet pipe 2 is provided with a protrusion 10, and the hollow bracket 6 is provided with a groove 11 corresponding to the protrusion 10. . The hollow support 6 is connected in rotation with the cleaning pipe 8, and the outlet pipe ...

Embodiment 2

[0041] Such as Figure 7 As shown, the car brake disc cleaning machine, the difference between this embodiment and the above embodiment is that it is also provided with a rotating mechanism for rotating the cleaning part 4, including a connecting rod 29 connected with the motor and a dial for stirring the cleaning pipe 8 The rod 30 and the connecting rod 29 are fixedly connected with the motor. The driving rod 30 is provided with a chute 31 and a slot 32 . The driving rod 30 is slidably connected with the water pipe through the chute 31 .

[0042] During specific implementation, by setting the rotating mechanism as the connecting rod 26 connected with the motor and the driving rod 30 for stirring the cleaning pipe 8, the motor drives the connecting rod 29 to rotate so as to drive the driving rod 30 to rotate, and the driving rod 30 and the water pipe Relative sliding occurs, and due to the limitation of the length of the connecting rod 29, the driving rod 30 can only be rotate...

Embodiment 3

[0044] Such as Figure 8 As shown, the car brake disc cleaning machine, the difference between the present embodiment and the second embodiment is that the cleaning belt 22 is divided into two layers with different materials, wherein one layer is the cleaning layer 23, and its material is cotton cloth, and the other layer is soft magnetic Sheet 24.

[0045] During specific implementation, the cleaning belt 22 is divided into two layers with different materials, one of which is cotton cloth, and the other is a soft magnetic sheet 24 . Compared with the rubber material, the rubber has a higher density. When the cleaning pipe 8 rotates, the rubber may not be able to cling to the brake disc 5 due to the centrifugal force due to its own weight, and the purpose of cleaning cannot be achieved; the cotton material is lighter, and the cleaning pipe 8 When rotating, the cotton cloth is more likely to stick to the brake disc 5, which is convenient for cleaning, and the characteristics o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com