Machining tooling for positioning holes in two ends of stainless steel bellows

A technology of bellows and positioning holes, which is applied in the field of processing tooling for positioning holes at both ends, to achieve the effects of convenient and quick operation, improved processing efficiency, and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

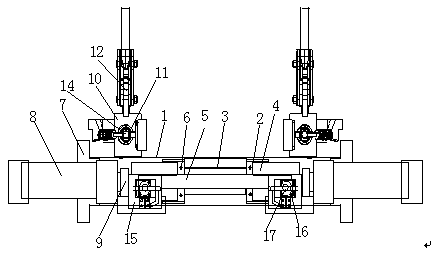

[0014] Example 1, such as figure 1 , 2 As shown, a processing tool for positioning holes at both ends of a stainless steel bellows, including a workbench 1, is characterized in that: a group of pipe body port clamps arranged on the workbench 1 and a set of pipe body port clamps arranged on the upper part The positioning holes are punched into a structure, the workbench 1 includes a strip-shaped table top, and a pipe support platform is arranged on the top of the table, and the pipe support platform includes a sliding groove 2 arranged in the workbench. An adjustment seat 3 is provided in the sliding groove 2, and a pipe body support seat 4 is provided in the adjustment seat 3. The pipe body support seat 4 is provided with a limit groove 5 for placing the pipe body. The pipe body supporting seat 4 and the slide groove 2 are provided with position adjusting bolts 6 .

[0015] The pipe body port clamping includes a cylinder connecting seat 7, a pneumatic cylinder 8 arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com