Printing film laminating device

A lamination device and lamination technology, applied in printing, printing presses, lamination devices, etc., can solve the problems of easy adhesion of dust, affecting lamination quality, lamination bubbles, etc., to avoid potential safety hazards, safe operation, The effect of simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

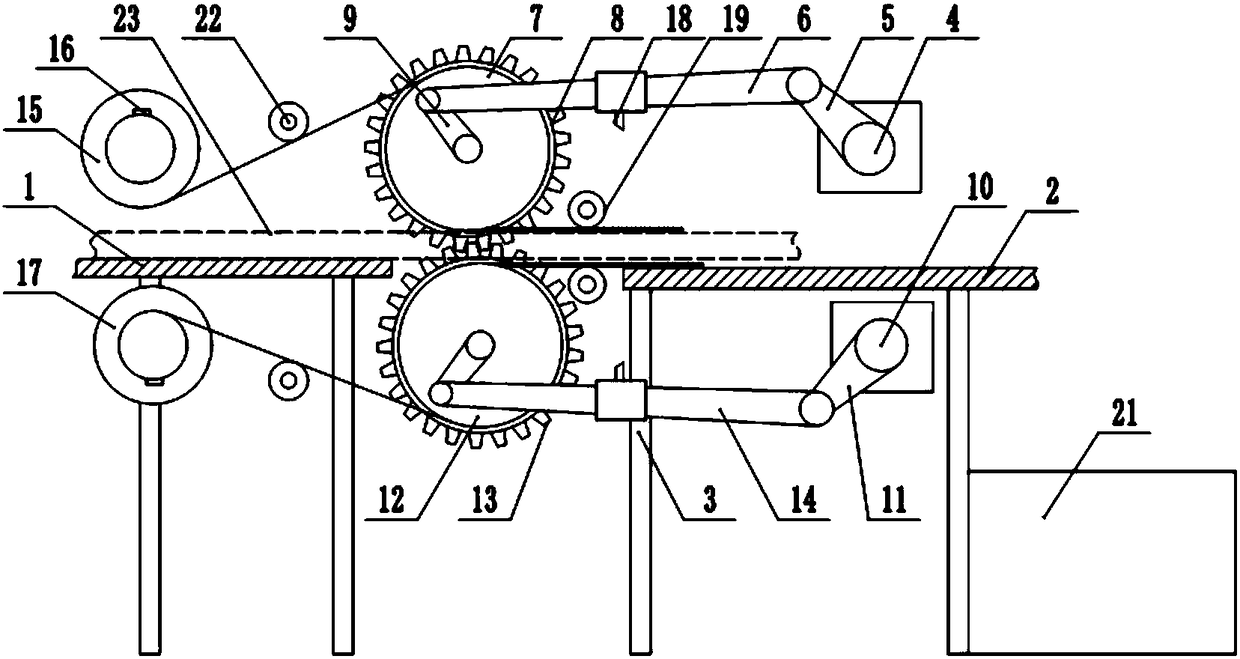

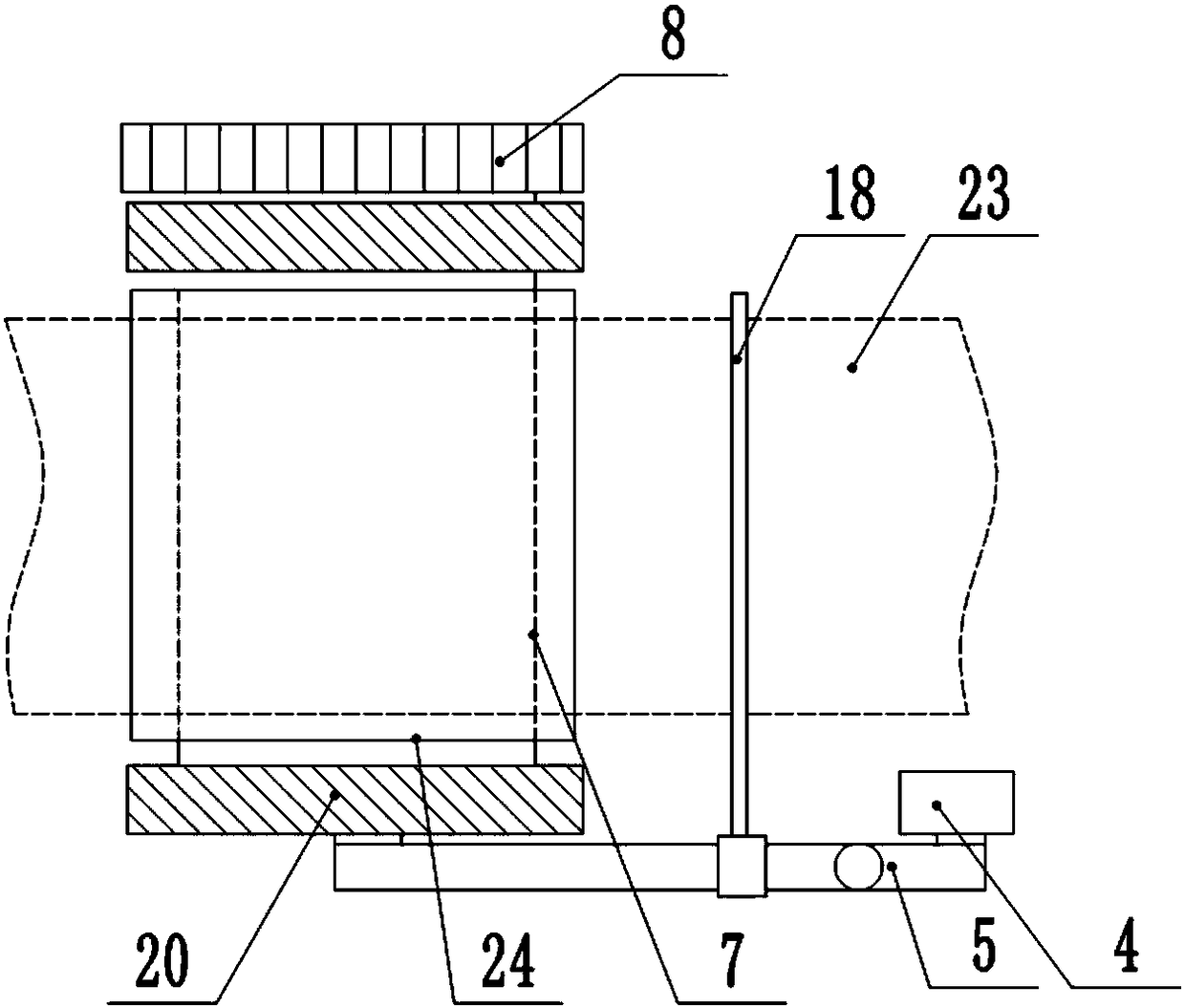

[0019] The reference numerals in the accompanying drawings of the description include: the first conveyor belt 1, the second conveyor belt 2, the support rod 3, the drive shaft 4, the first drive rod 5, the second drive rod 6, the driving coating roller 7, the driving gear 8, First connecting rod 9, driven shaft 10, first driven rod 11, driven lamination roller 12, driven gear 13, second driven rod 14, first peeling roller 15, splint 16, second peeling roller 17. Cutting knife 18, first support roller 19, first pressing block 20, collection box 21, first transition roller 22, cardboard 23, film roll 24.

[0020] The embodiment is basically as attached figure 1 Shown: a printing and laminating device, including a frame and a transmission mechanism, the transmission mechanism includes a first conveyor belt 1 and a second conveyor belt 2, the first conveyor belt 1 and the second convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com