Novel double-cylinder straight suction nozzle

A double-tube, direct-suction technology, applied in the direction of conveyors, transportation and packaging, conveying bulk materials, etc., can solve the problems of affecting the end surface clearance of the inner and outer pipes, inconvenient disassembly, and increased pressure loss, so as to reduce the difficulty of adjustment and process. Difficulty, the effect of accelerating material absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

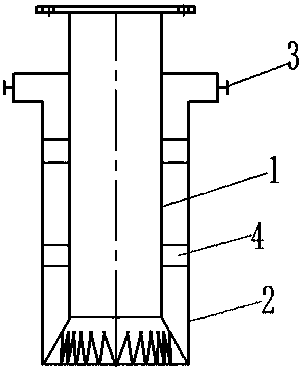

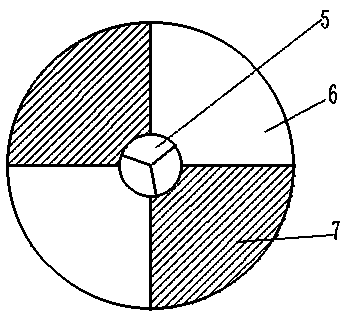

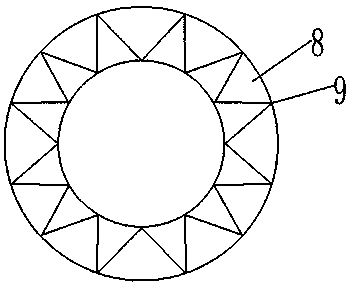

[0023] Attached below figure 1 , 2 , 3, the specific implementation manner of the present invention is described in further detail. Such as figure 1 A new type of double-tube straight suction nozzle shown is mainly composed of two parts, the inner tube (1) and the outer tube (2). The inner tube (1) and the outer tube (2) are integrally welded and fixed together. The bottom of the tube (1) is set as a bell mouth, and a zigzag notch with a certain height is processed on the bottom edge of the bell mouth. The connection method between the zigzag notch at the bottom of the inner tube and the outer tube is as follows: image 3 shown. Two openings are arranged symmetrically on the upper end of the outer tube (2), and two valves (3) are installed at the openings. The amount of secondary air entering is controlled by adjusting the opening size of the valve (3). When the suction nozzle is working, insert the suction nozzle into the material pile to an appropriate depth, a certain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com