Tunnel cross-section primary lining construction process

A technology of construction technology and cross-section, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of scaffolding erection height and span, limited external transportation of muck, and large amount of muck, and achieve good promotion and application prospects. The effect of reducing risk loss and producing less slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] see Figure 4-Figure 10 , a tunnel section initial laying construction process, comprising the following steps:

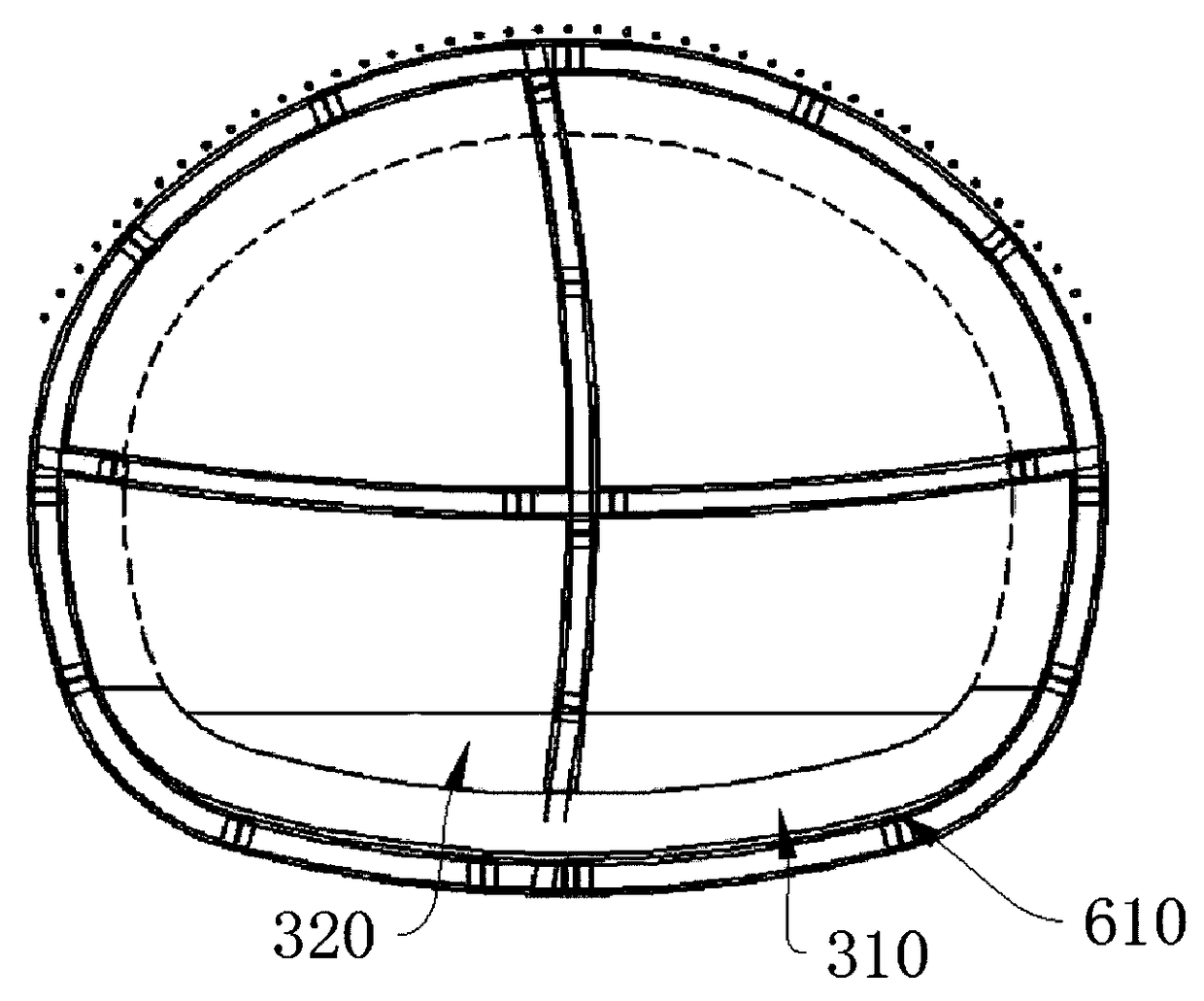

[0043] S1, see Figure 4 According to the 6m section, the lower part of the middle partition wall and the primary concrete within the thickness range of the secondary initial laying of the inverted arch are chiseled, and the lower part of the grid main reinforcement 500 is cut off to form the filling part 320; the grid main reinforcement 30cm below the inverted arch surface Not cut off, poured directly in the inverted arch;

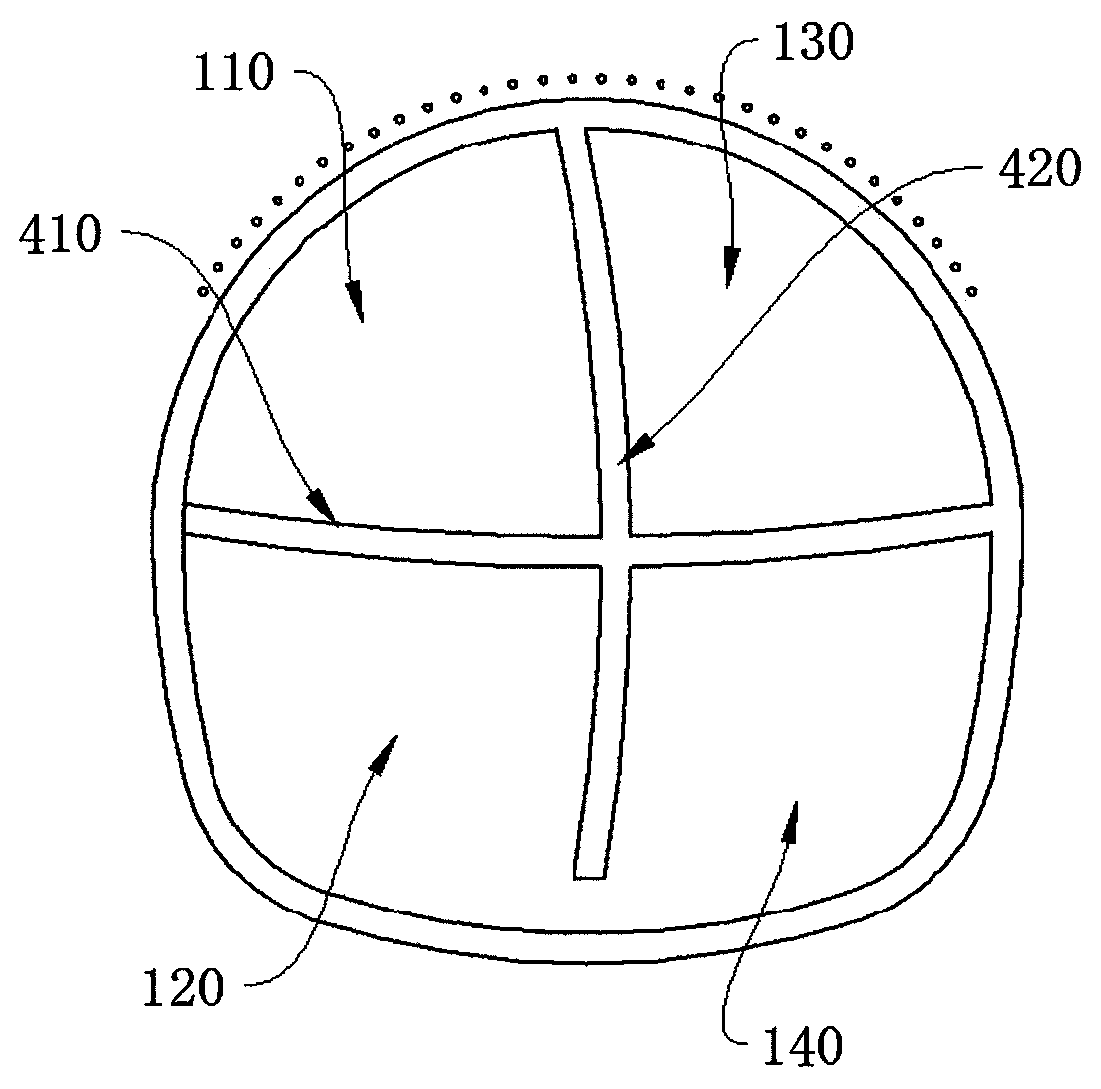

[0044] S2, see Figure 5 , laying waterproof layer 610, tying steel bars, pouring inverted arch concrete, pouring filling part 320, forming inverted arch 310;

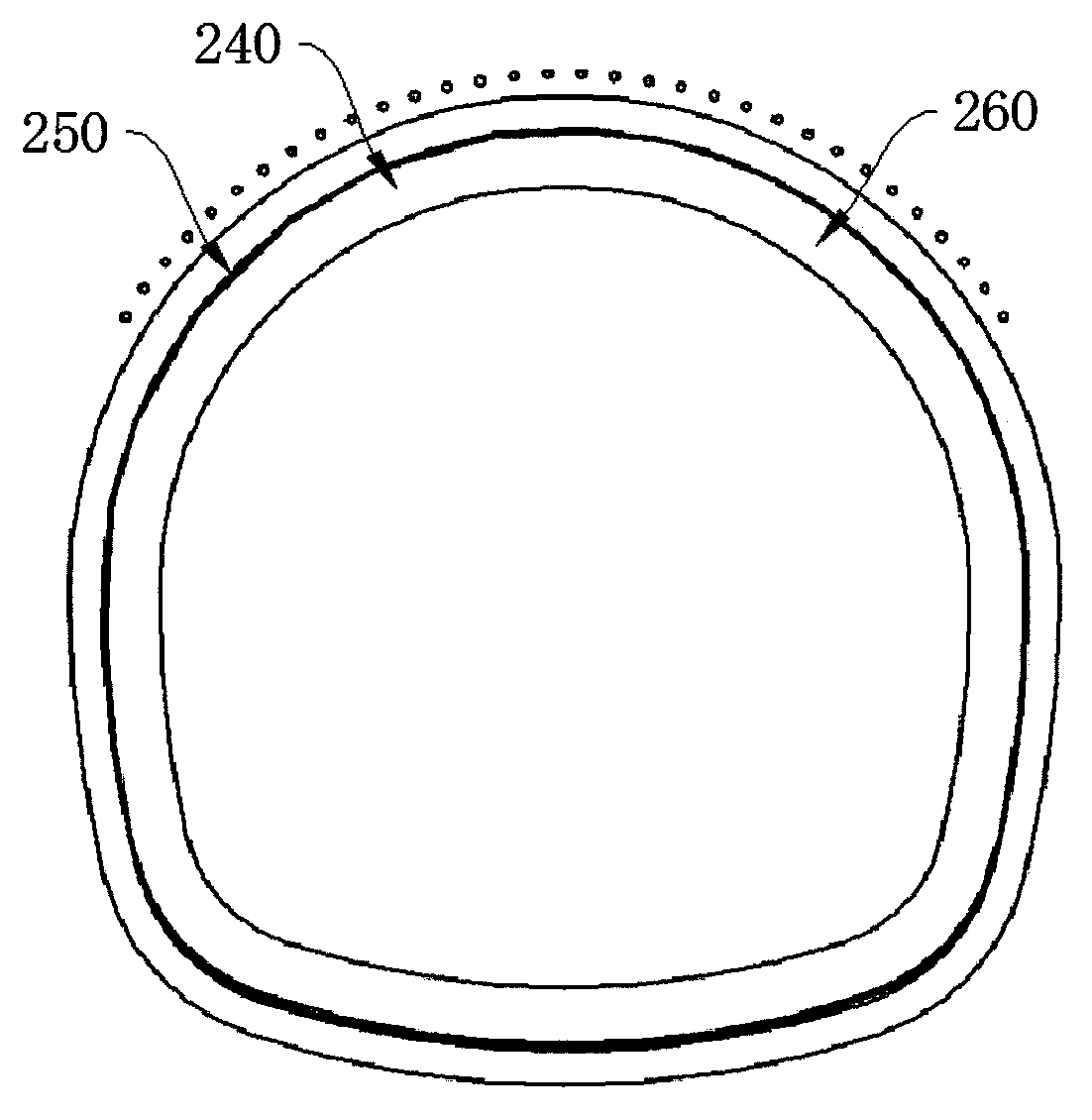

[0045] S3, see Image 6 , demolish within 1m at both ends of the partition 410, remove the primary concrete within 2m from the top of the partition (to the position of the gusset plate), and cut off the main bars of the grid;

[0046] S4, see Figure 7 , set up the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com