Cloth dehydrator with self-adaptive damping device

A shock absorber and dehydrator technology, applied in the direction of springs/shock absorbers, support machines, mechanical equipment, etc., can solve problems such as automatic adjustment of the shock absorber effect of the shock absorber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

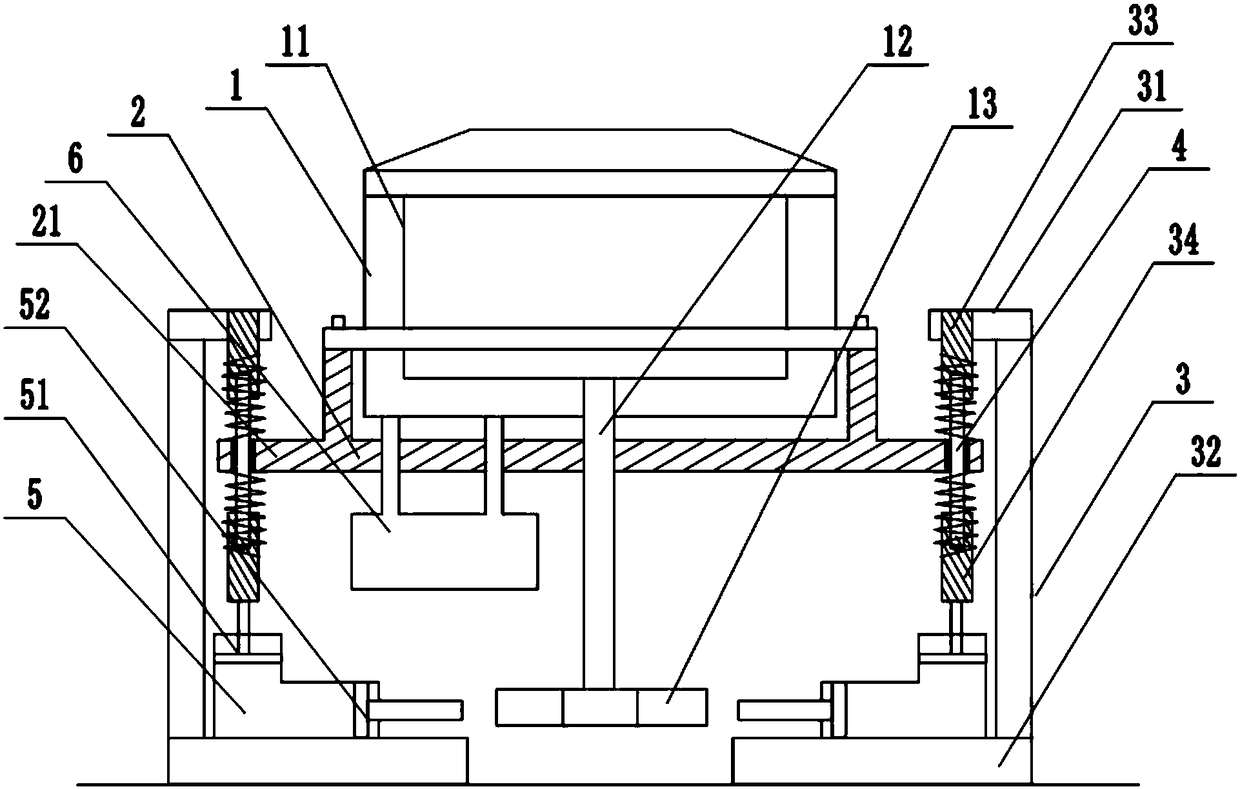

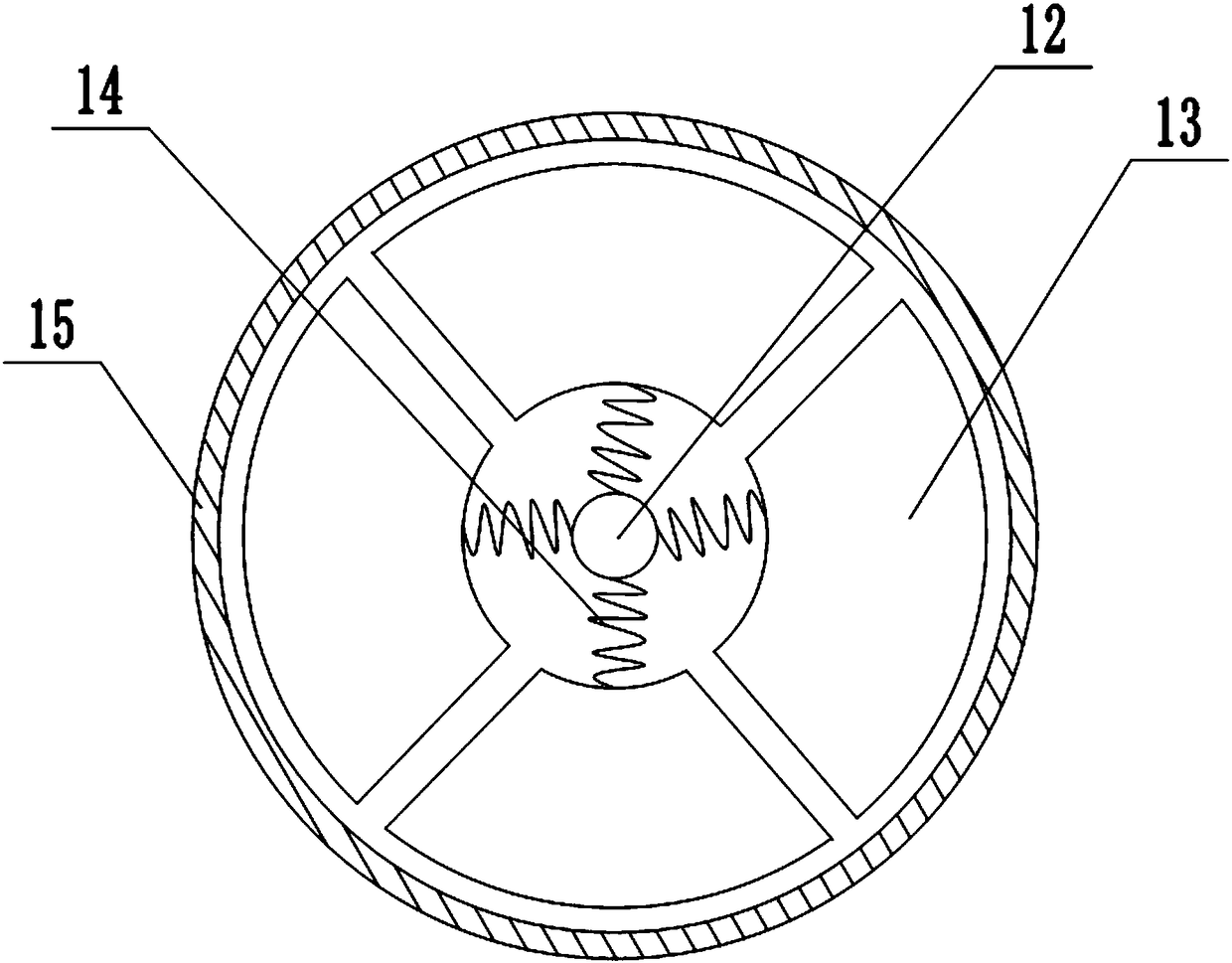

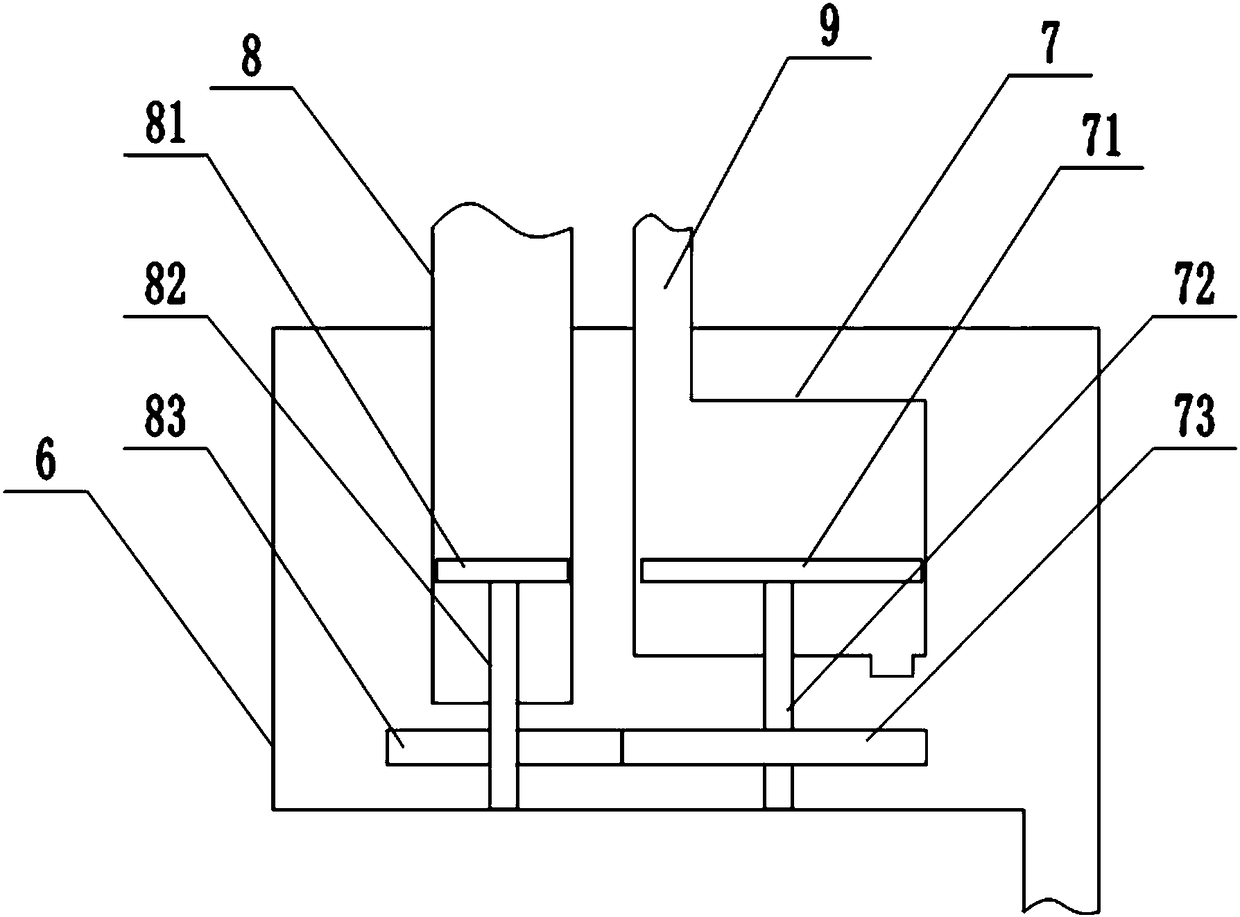

[0018] The reference signs in the drawings of the description include: dehydrator 1, inner cylinder 11, rotating rod 12, arc block 13, tension spring 14, elastic collar 15, base 2, connecting part 21, buffer frame body 3, upper support Part 31, lower support part 32, upper adjustment rod 33, lower adjustment rod 34, guide rod 4, L-shaped hydraulic cylinder 5, first piston 51, second piston 52, noise reduction device 6, vacuum box 7, fan blade 71, the second rotating shaft 72, the second gear 73, the liquid catheter 8, the helical blade 81, the first rotating shaft 82, the first gear 83, and the air guiding tube 9.

[0019] The embodiment is basically as attached Figures 1 to 3 Shown: a fabric dehydrator with an adaptive damping device, including a dehydrator 1 and a base 2 for supporting the dehydrator 1, the base 2 is provided with an outwardly extending connecting por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com