Calculating method for determining gas content of gas-liquid two-phase flow in ladle

A technology of gas-liquid two-phase flow and calculation method, which is applied in the simulation field of hot metal pretreatment and desulfurization process, and can solve the problems of less calculation and the inability to verify the gas-liquid two-phase flow in the ladle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

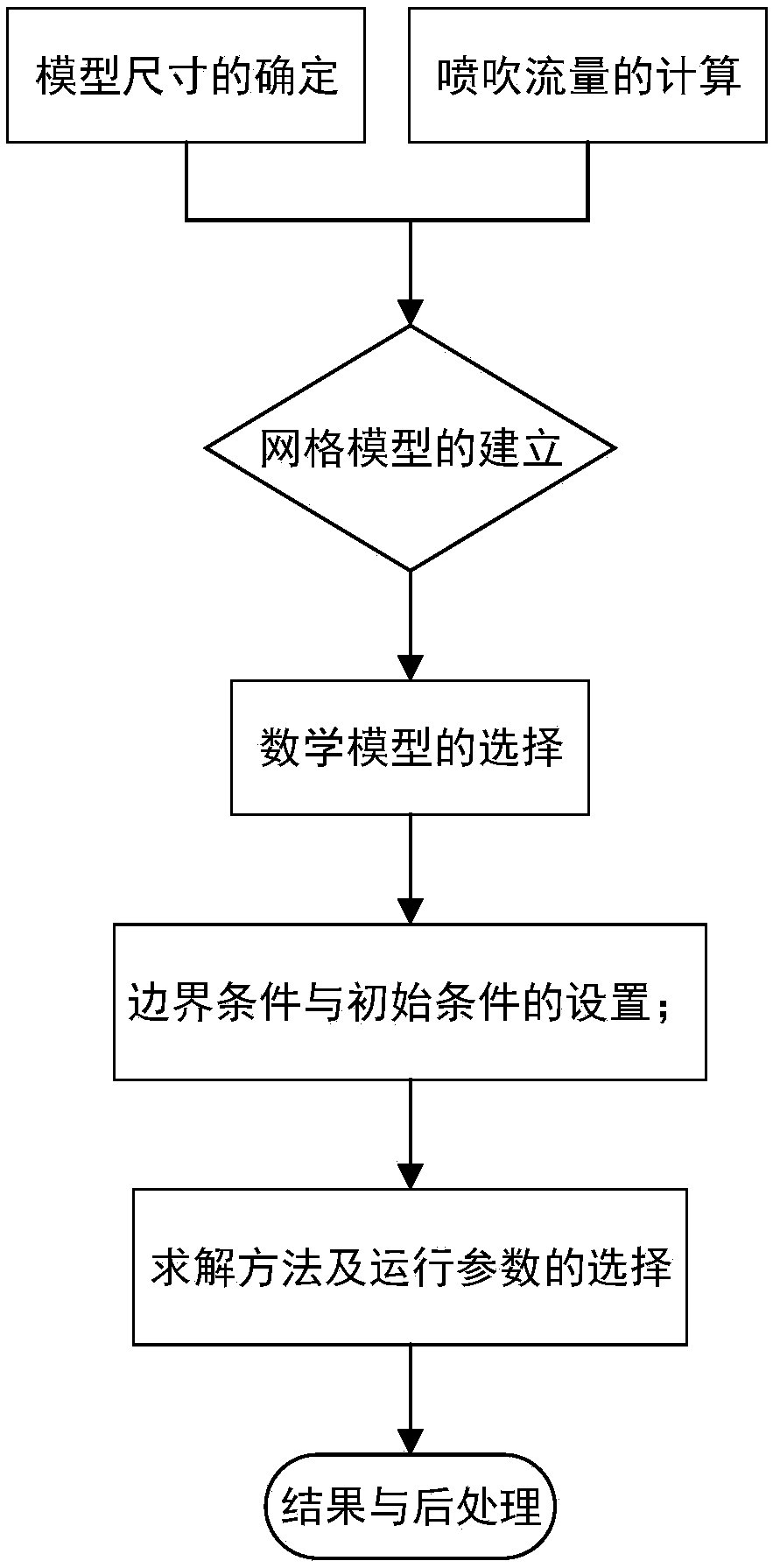

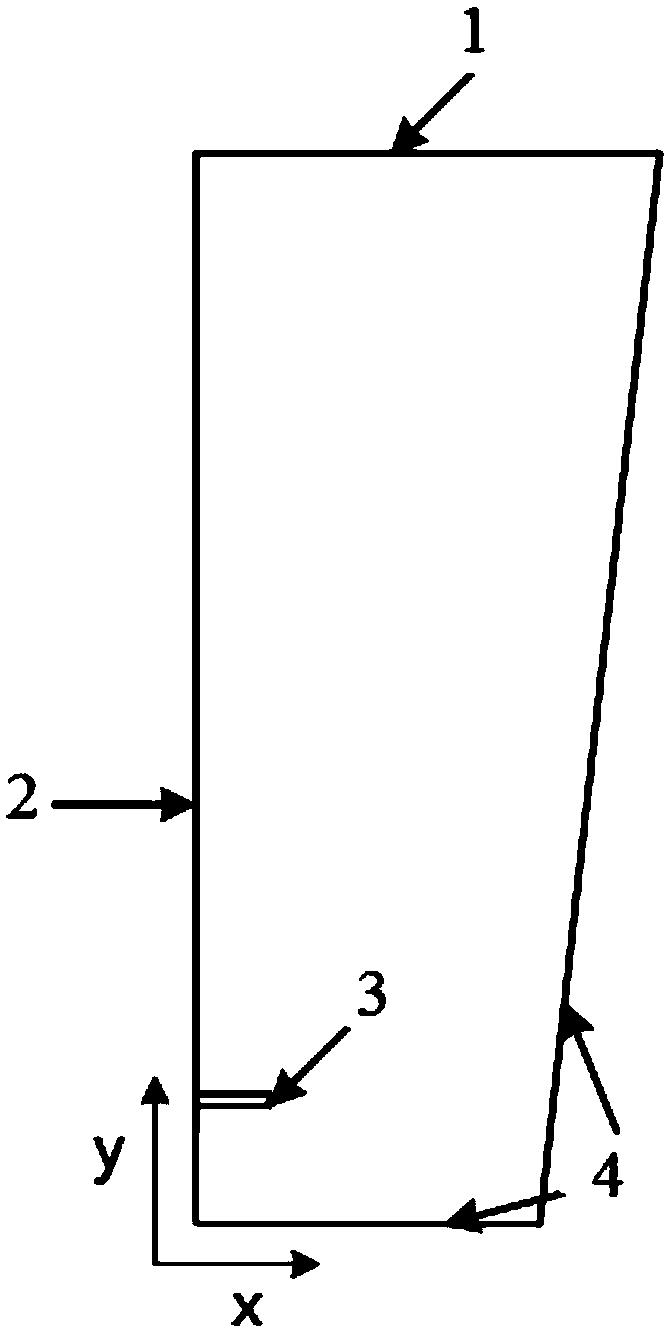

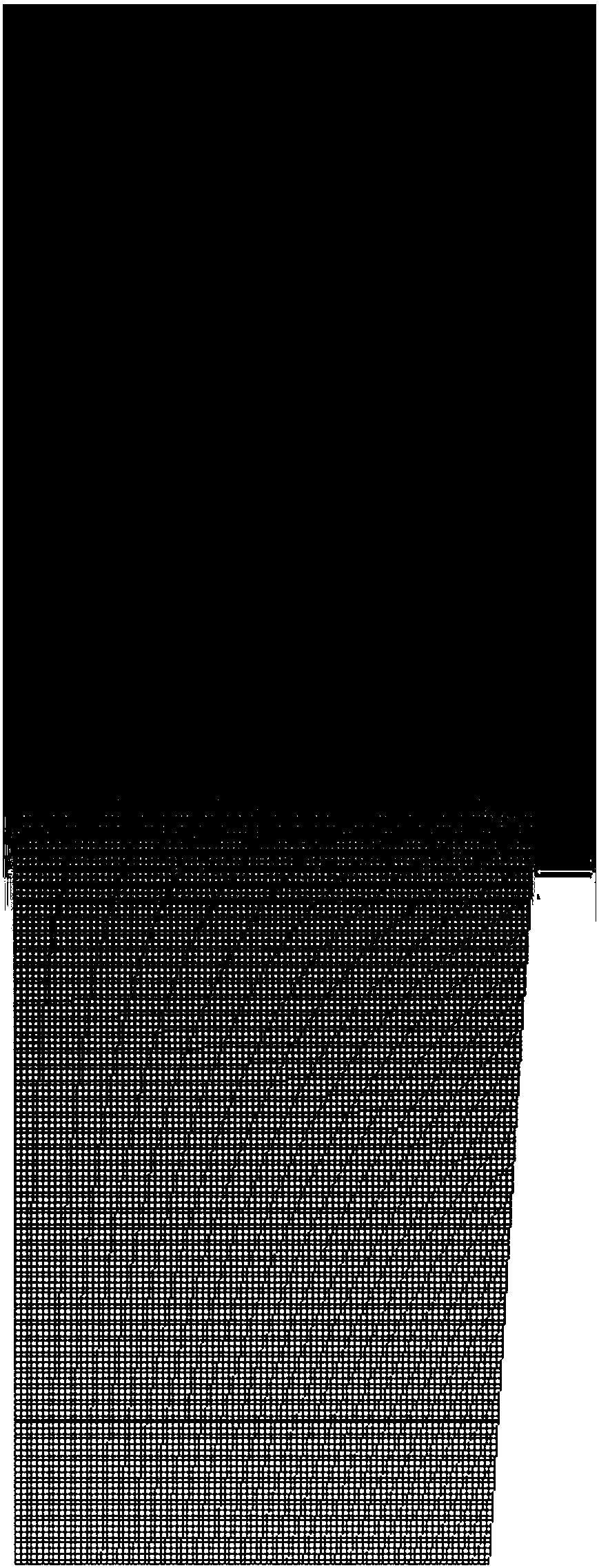

[0090] The numerical simulation method of the gas-liquid two-phase flow gas holdup in the ladle-water model, (wherein the present invention adopts the blowing desulfurization method, and the spray gun adopts an inverted "T" type spray gun) comprises the following steps:

[0091] Step 1. Collection of process parameters: On-site investigation of the steelmaking workshop of a steel factory to obtain the process parameters of the ladle during the actual production process, including: diameter of the upper mouth of the ladle, diameter of the bottom of the ladle, height of the ladle, depth of spray gun insertion, nozzle Diameter, injection flow rate of magnesium powder and carrier gas flow rate.

[0092] Step 2. Calculation of the size of the water model: According to the process parameters collected in step 1, including the diameter of the upper mouth of the ladle, the diameter of the bottom of the ladle, the height of the ladle, the insertion depth of the spray gun, and the diamet...

Embodiment 2

[0157] Step 1. Collection of process parameters: On-site investigation of the steelmaking workshop of a steel factory to obtain process parameters in the actual production process, including: diameter of the upper mouth of the ladle, diameter of the bottom of the ladle, height of the ladle, depth of spray gun insertion, diameter of the nozzle, Magnesium powder injection flow rate and carrier gas flow rate. Its specific data are shown in Table 1:

[0158] Table 1 process parameters

[0159]

[0160]Step 2. Calculation of the size of the water model: According to the process parameters collected in step 1, including the diameter of the upper opening of the ladle, the diameter of the bottom of the ladle, the height of the ladle, the insertion depth of the spray gun, and the diameter of the nozzle, the water model is determined based on the geometric similarity theory The geometric size of the water model, the similarity ratio is 1:5, that is, the size is reduced by 1:5, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com