Pipeline system for vehicle battery cabin fire fighting device

A technology of fire extinguishing device and piping system, which is applied in the field of structural design of piping system for fire extinguishing devices, can solve the problems that metal pipes are difficult to achieve bending or arc transition, and cannot be used, and achieve good effect, beautiful appearance and convenient pipe layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

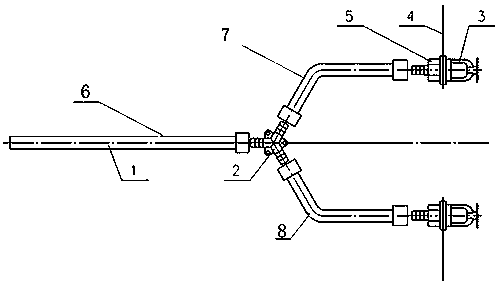

[0020] Such as figure 1 As shown, a pipeline system for a vehicle battery compartment fire extinguishing device includes a pipeline 1, a tee connector 2, a nozzle 3, a nozzle bracket 4, and an adapter 5; the tee connector 2 is fixed on the vehicle body and connected to the vehicle Skeleton connection; the pipeline 1 includes pipeline A6, pipeline B7 and pipeline C8; the three connection ports of the three-way connector 2 are respectively connected to pipeline A6, pipeline B7 and pipeline C8; the other end of the pipeline A6 is connected to the fire extinguishing device, The pipeline B7 and the pipeline C8 are respectively connected with two adapters 5, and two nozzles 3 are connected on the adapter 5; the connection between the adapter 5 and the nozzles 3 is also provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com