Boiler flue gas purification and desulfurization device

A desulfurization device, boiler flue gas technology, applied in the direction of gas treatment, chemical instruments and methods, the use of liquid separation agent, etc., can solve the problems of endangering ecology, environmental pollution ash and sulfide, and unsatisfactory boiler desulfurization efficiency , to achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

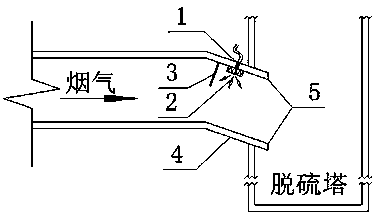

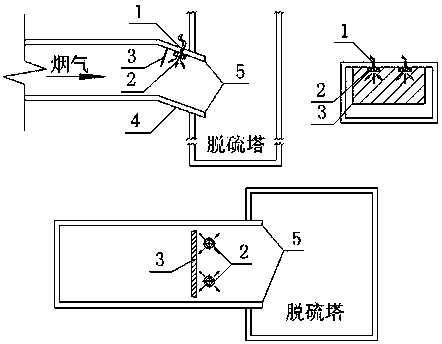

[0011] Such as figure 1 As shown, the present invention is a high-efficiency desulfurization device for boiler flue gas, which includes a desulfurization liquid inlet, a nozzle, a liquid barrier, an inclined flue, and a flue outlet. When the device is in normal operation, the boiler flue gas enters the flue from the flue gas inlet under the action of the induced draft fan. After contacting the desulfurization liquid, the sulfide and impurities in the flue gas are neutralized by the desulfurization liquid and then flow into the desulfurization tower to achieve more efficient Purification and desulfurization. The liquid baffle can prevent the spraying of desulfurization liquid from the nozzle and splash into the flue to form backflow. The desulfurization liquid sprayed from the nozzle neutralizes the flue gas and then discharges into the desulfurization tower along the inclined flue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com