Automatic milling device and milling method thereof

A powder-grinding and automatic technology, applied in spice mills, coffee mills, kitchen utensils, etc., can solve problems such as air or other things doping, poor taste of powder, non-removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

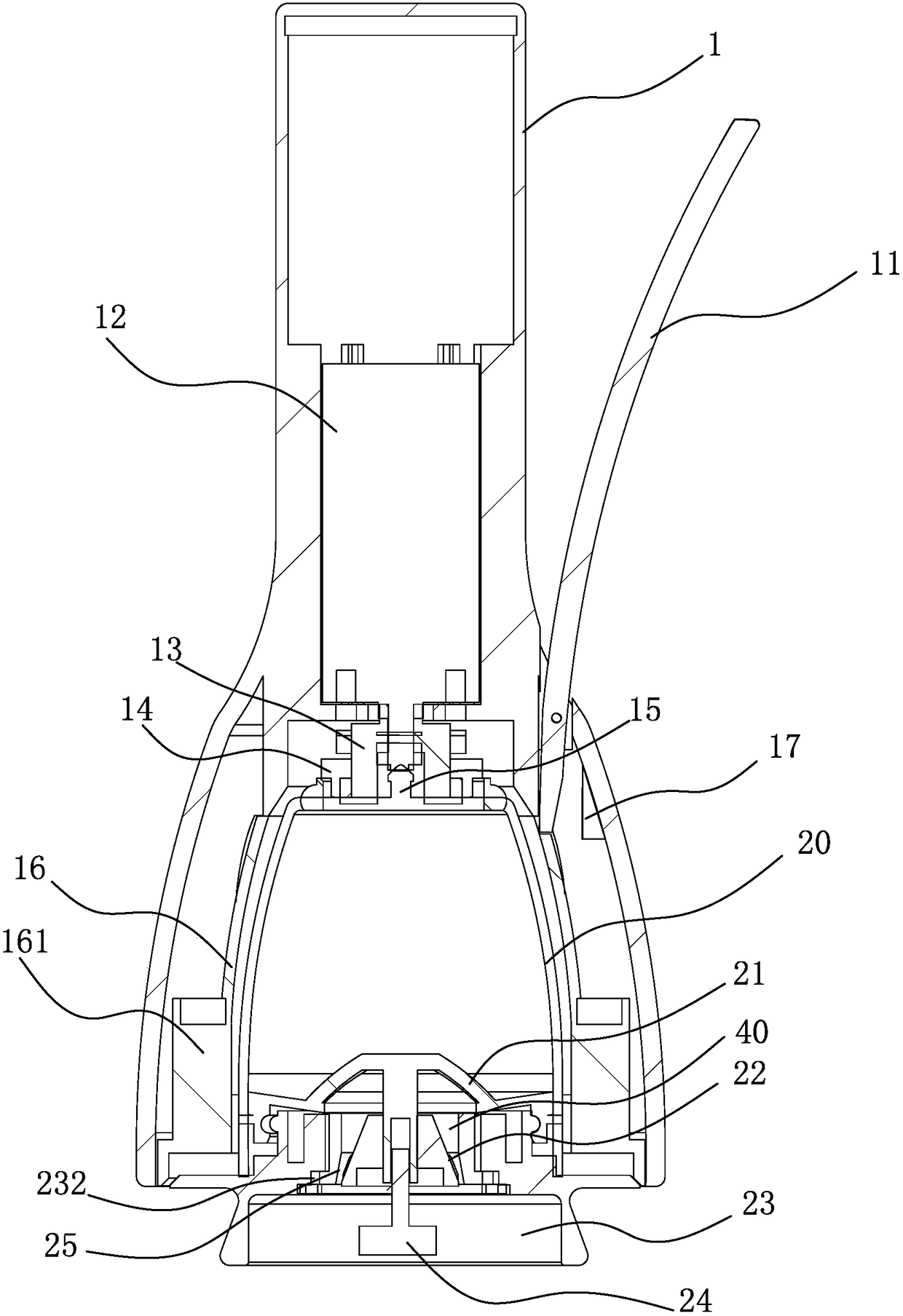

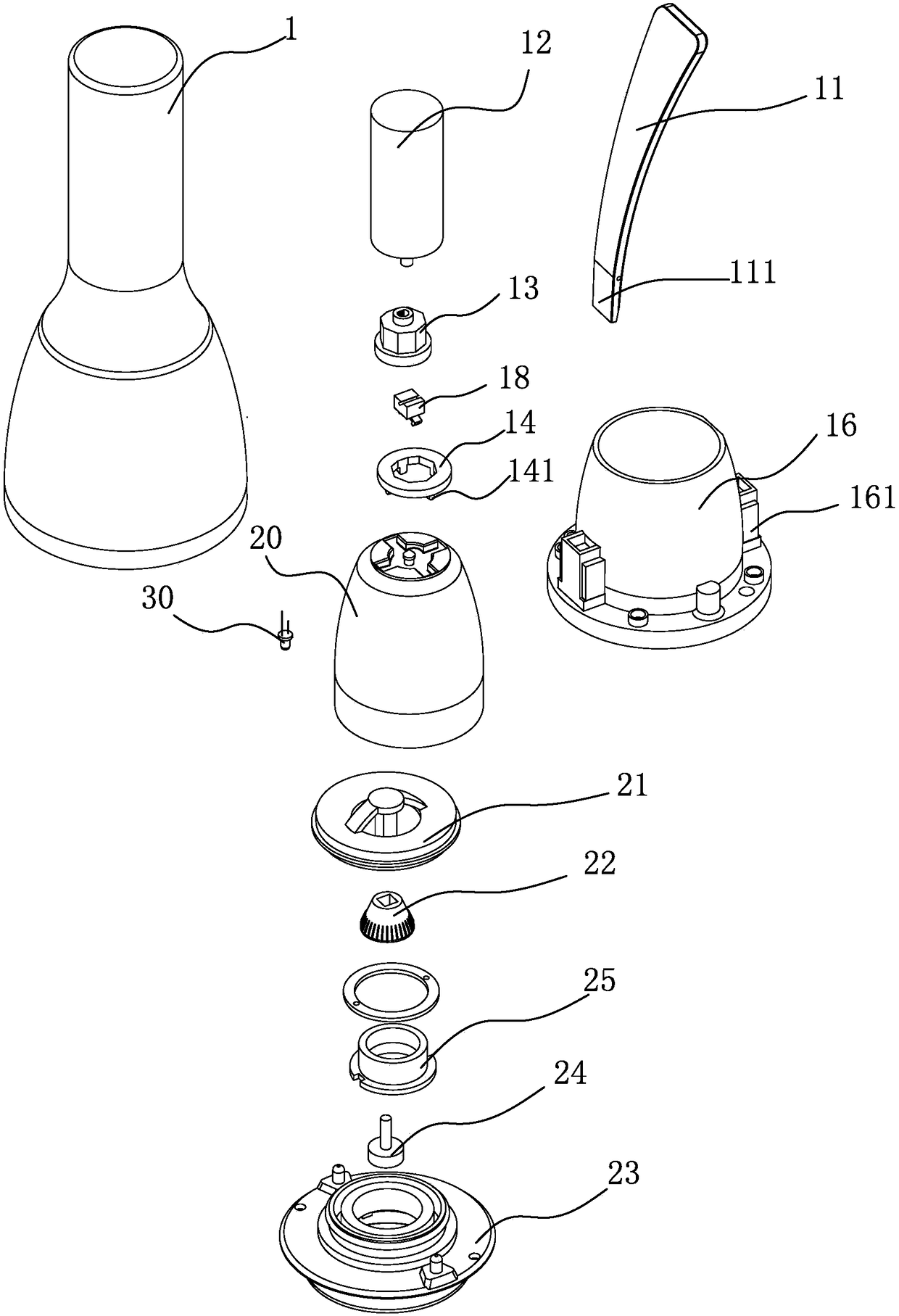

[0030] Such as Figure 1-9 In the specific embodiment shown, the automatic pulverizer provided by this embodiment can be used indoors or outdoors. When grinding various materials, different grinding sleeves 25 and grinding heads 22 are used, and it is not easy to mix other things when feeding. , to ensure the original taste of the material.

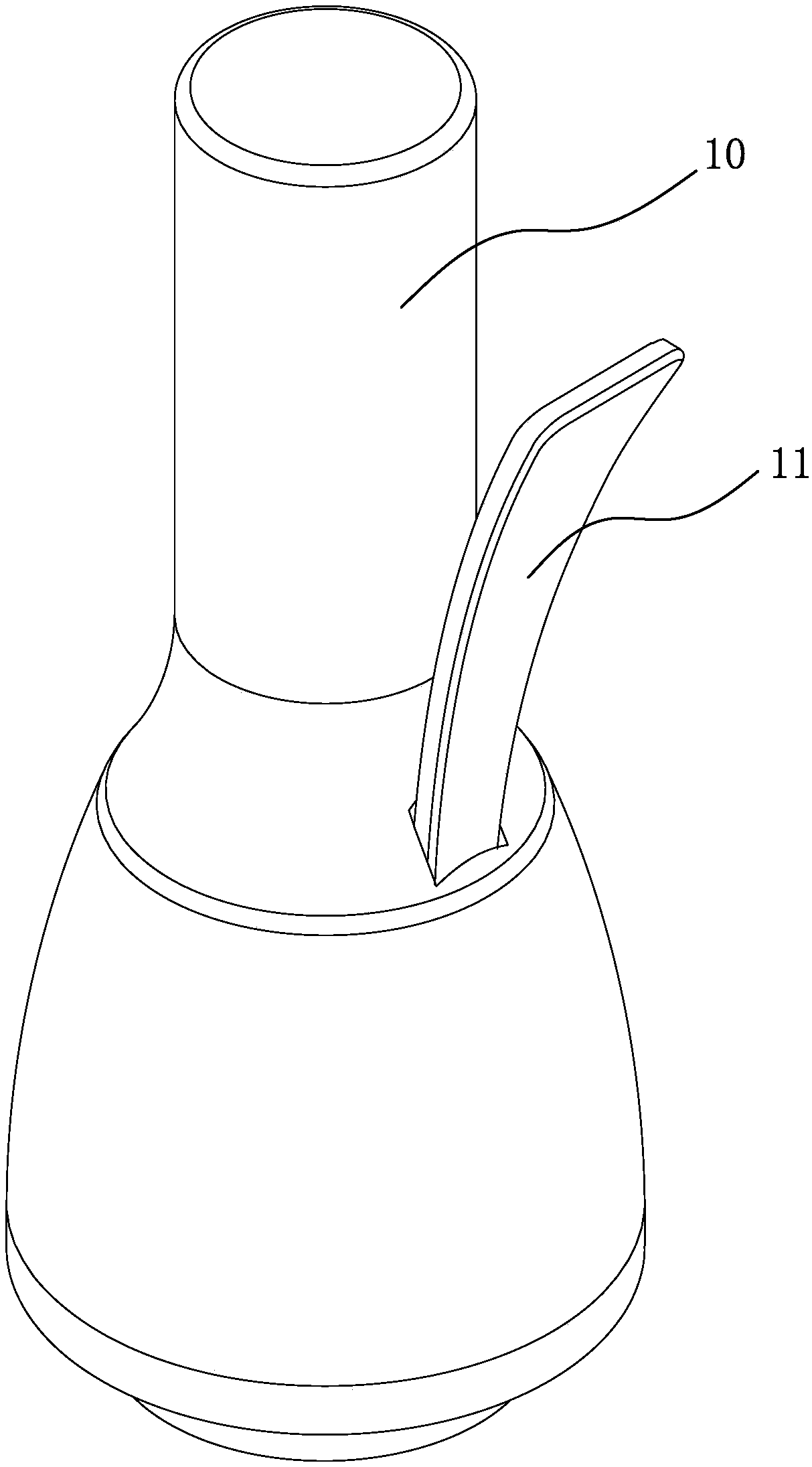

[0031] Such as figure 1 As shown, the present embodiment provides an automatic pulverizer, which includes a control structure and at least one cartridge assembly, the control structure includes a drive assembly and a connection structure, the drive assembly is connected to the connection structure, and the cartridge assembly includes a cartridge body 20, and The grinding head 22 fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com