Industrial automatic cutting device

A cutting device and industrial technology, applied in the direction of shearing devices, shearing machine accessories, shearing machine equipment, etc., can solve the problem of different degrees of deformation of the cut parts of the rotating metal sheet, affecting the accuracy of experimental analysis, and relatively large internal structure changes. Large and other problems, to achieve the effect of improving accuracy, low cost, reducing load changes and local deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is further described in detail through specific implementation methods:

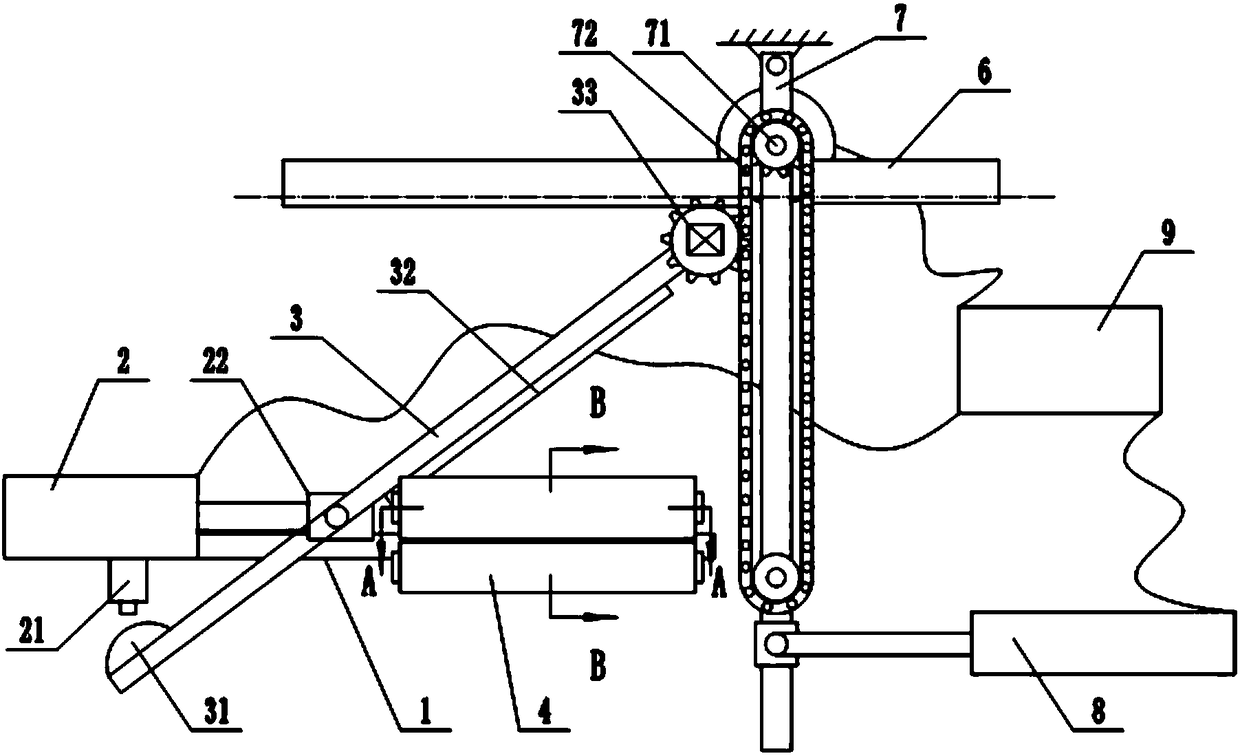

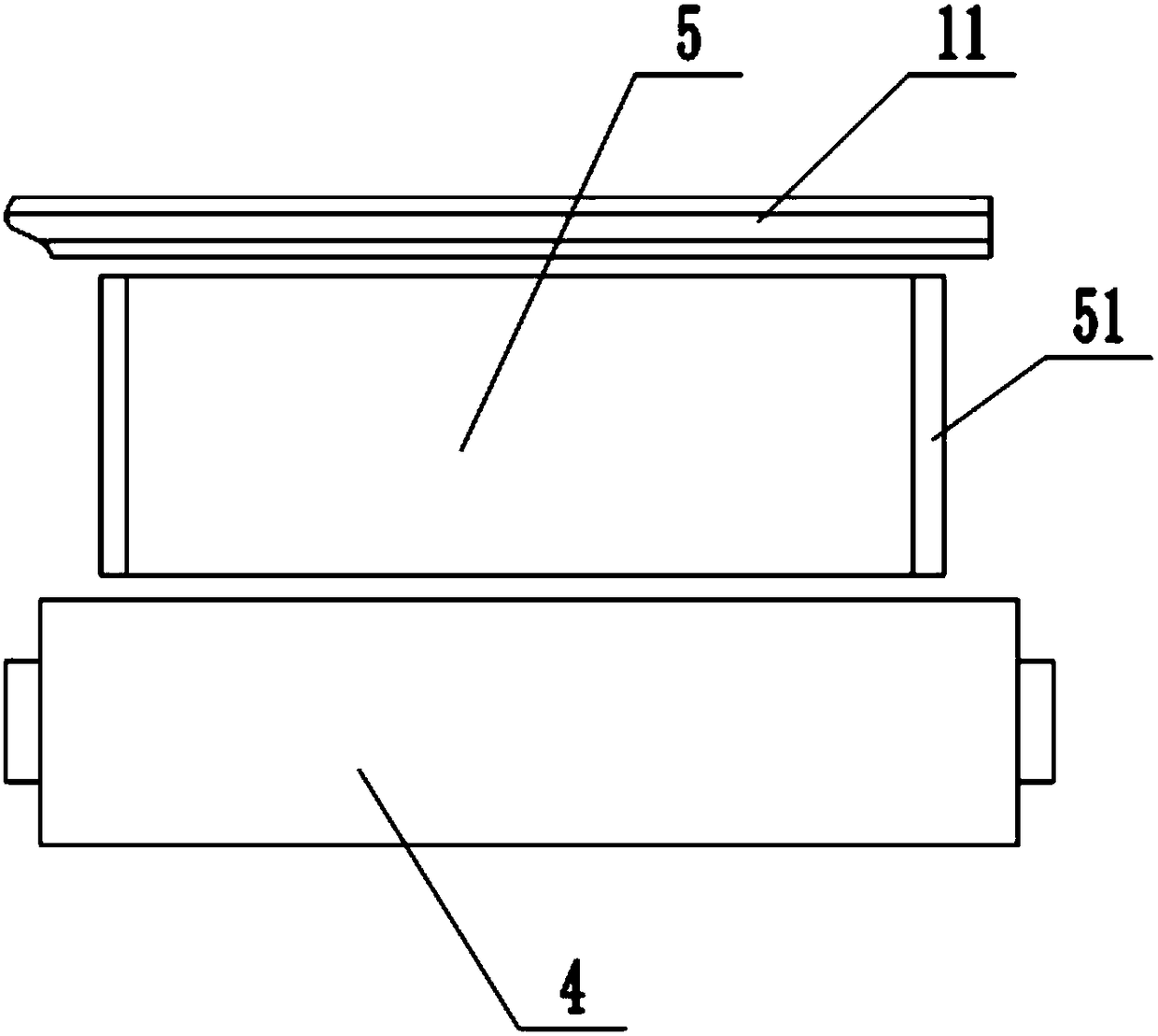

[0020] The reference signs in the accompanying drawings of the description include: cutting table 1, cutting groove 11, first push cylinder 2, booster valve 21, mounting block 22, connecting rod 3, spherical protrusion 31, cutter 32, driving sprocket 33 , Transport roller 4, guide groove 5, protective plate 51, limit rack 6, installation rod 7, transmission sprocket 71, chain 72, second push cylinder 8, central controller 9.

[0021] The embodiment is basically as attached figure 1 Shown:

[0022] The industrial automatic cutting device among the present invention comprises a pair of conveying rollers 4 arranged oppositely, connecting rod 3 and cutting platform 1, leave the gap that is used to pass through for the cutting piece between two conveying rollers 4, one side of this gap Opposite to the cutting table 1, the connecting rod 3 is arranged directly above the cutting table 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com