Automatic processing platform for core components of connectors

A technology of automatic processing and parts, which is applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of difficult precision control, low accuracy guarantee rate, and difficulty in novice training, so as to achieve fast processing speed, Measure Precisely, Control Precisely Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

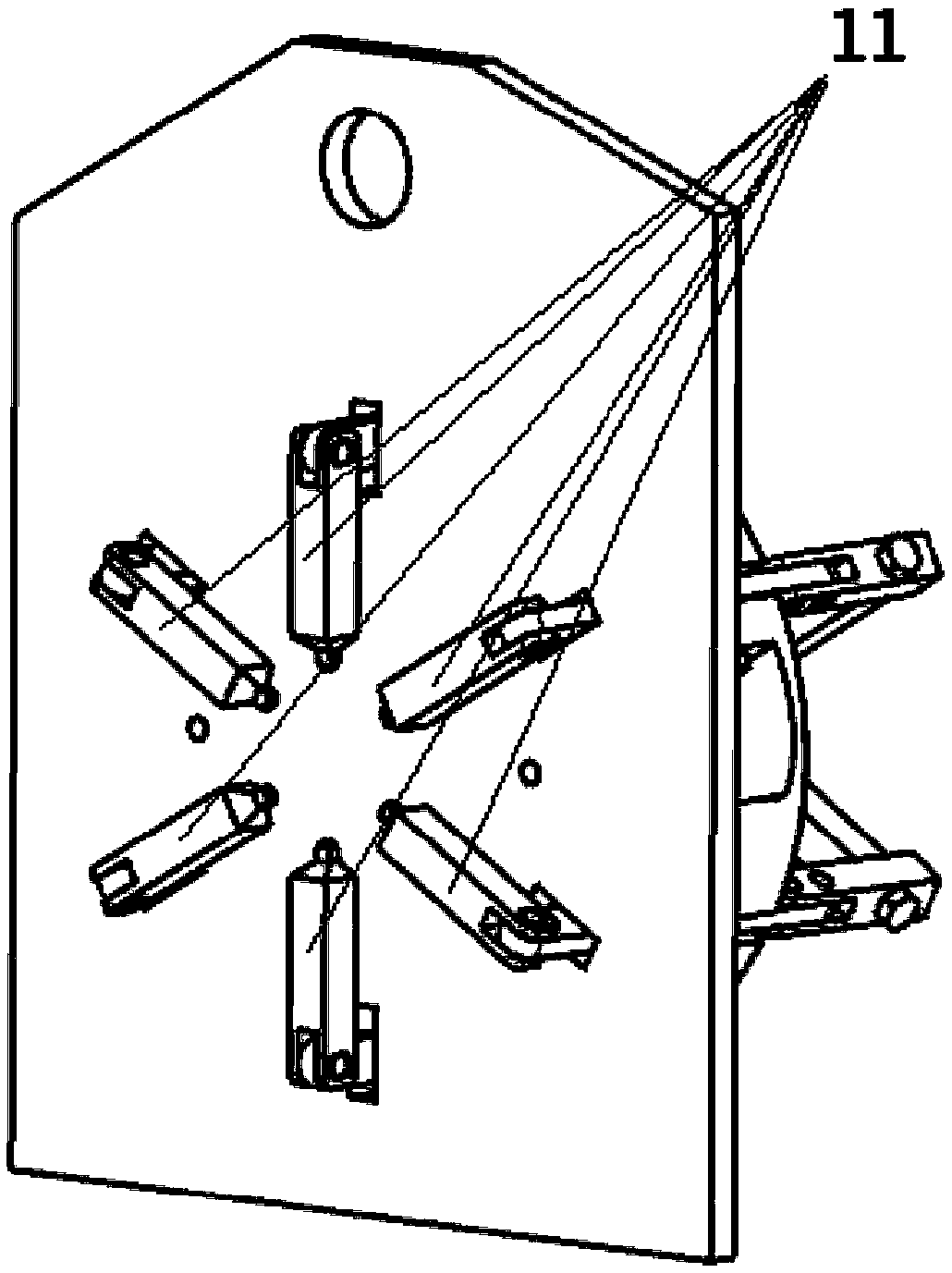

[0049] The automatic processing platform for the core parts of the connector is characterized in that: the automatic processing platform includes a workpiece pushing device, a processing device, a detection device and a workbench 1; the workpiece pushing device corresponds to the processing device, and the workpiece pushing device and the processing device are kept on the same axis On the center (that is, the processing position where the workpiece can correspond to the processing device), the entire automatic processing platform is controlled by the control cabinet and the display.

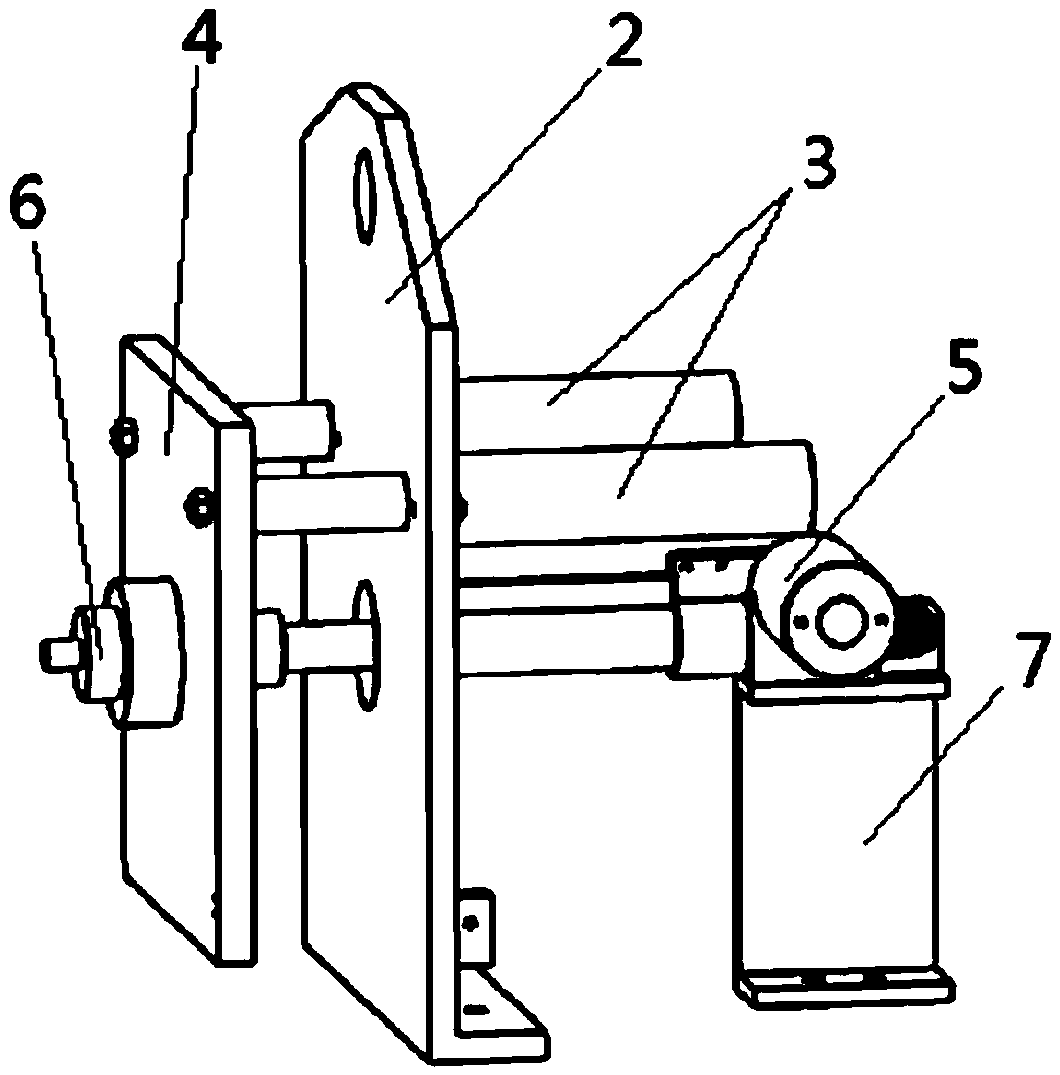

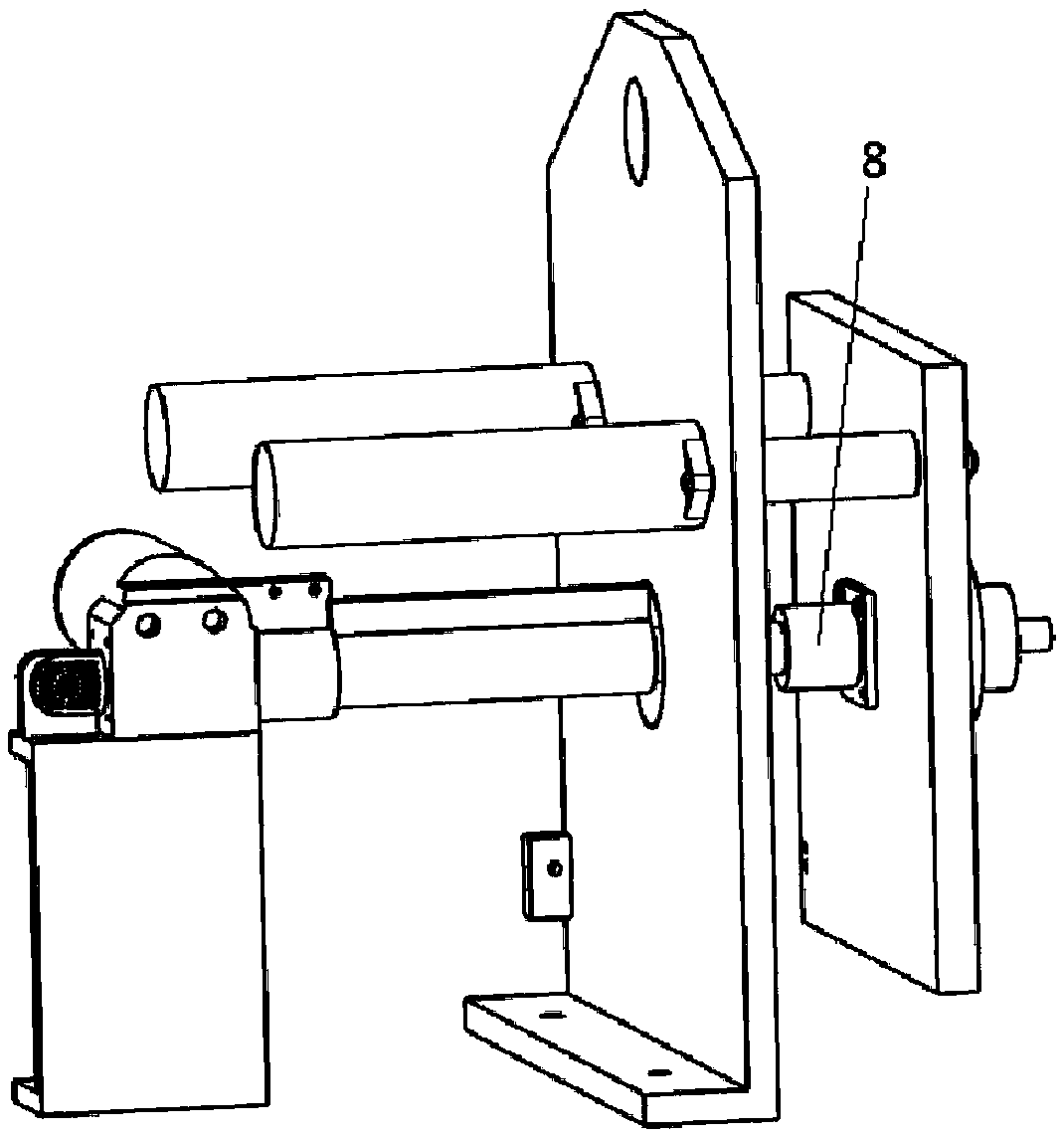

[0050] The workpiece pushing device includes a support frame 2, a balance cage 3, a baffle plate 4, a linear servo push rod motor 5, a special fixture 6, a push rod motor bracket 7 and a connecting device 8; the balance cage 3 is installed on the support frame 2, The special jig is installed on the front end of the baffle plate 4, and the baffle plate 4 is connected with the balance cage 3 to ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com