Torque wrench based on shape memory alloy

A memory alloy and torque wrench technology, which is applied in the field of wrenches, can solve the problems of narrow working space, large operating space, inability to meet the torque operation of pipeline bending, and achieve the effect of easy operation and expansion of the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

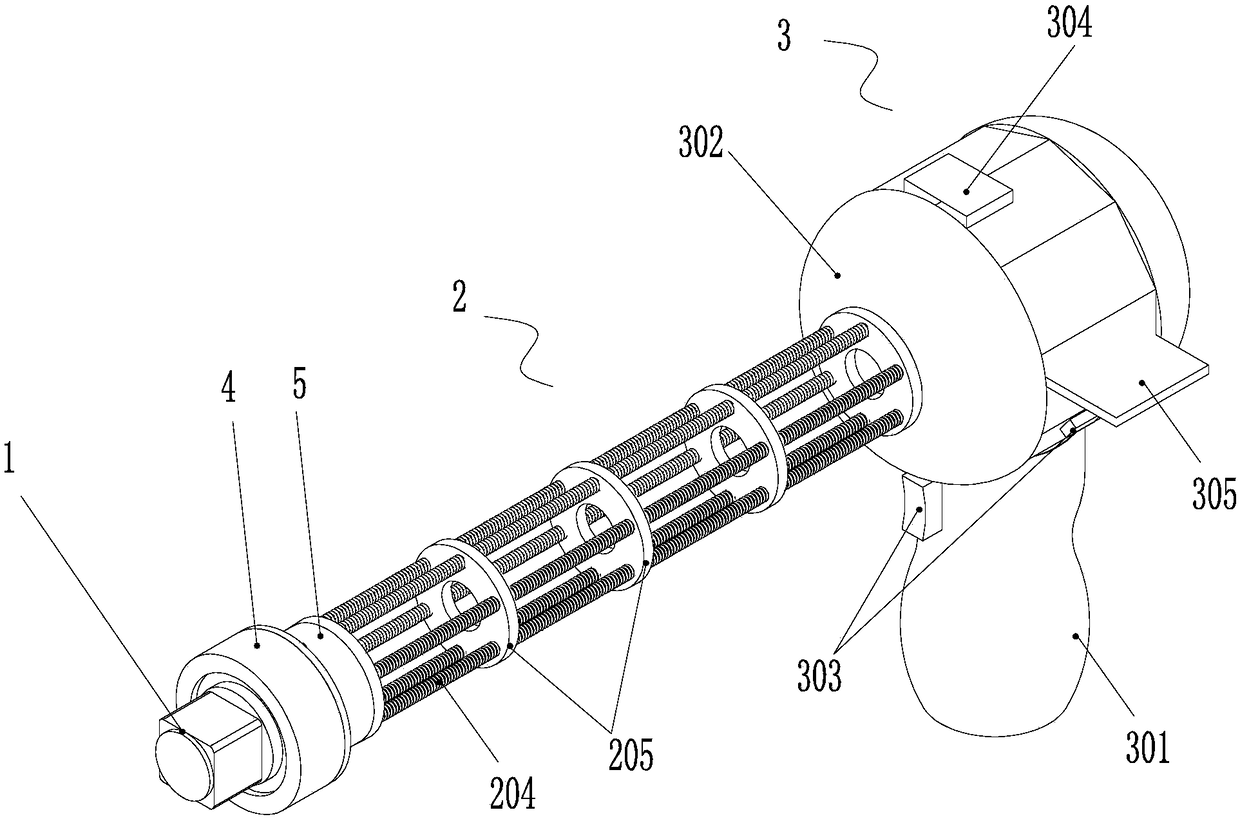

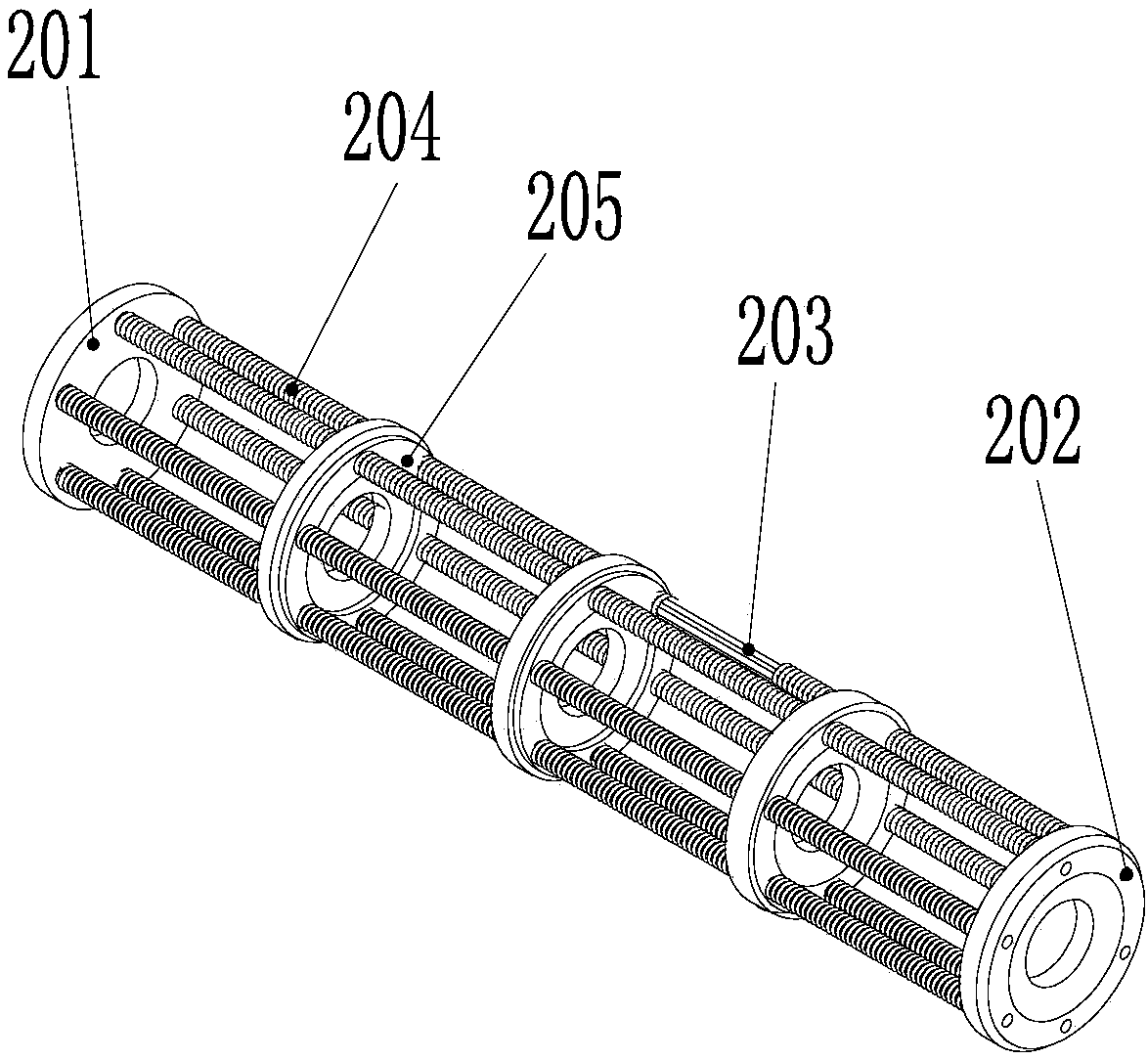

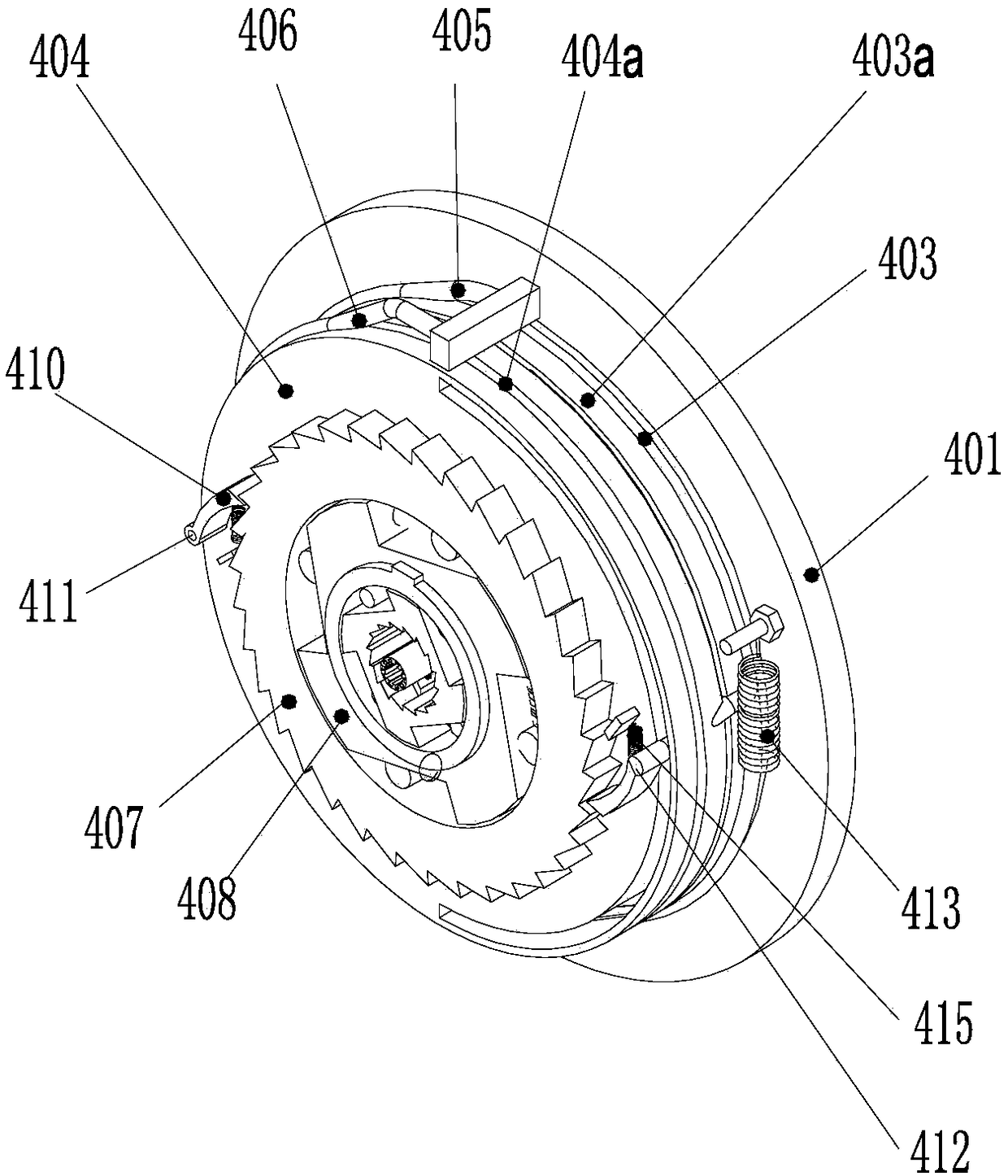

[0036] As shown in the figure: the torque wrench based on the shape memory alloy of this embodiment includes a wrench head 1 connected in sequence, a driving device for driving the wrench head 1, a wrench handle 2 and a hand-held operating mechanism 3, and the wrench head 1 is used for operation Threaded fasteners; the driving device can realize the rotation of the wrench head 1; the wrench handle 2 allows the wrench head 1 to be extended; the hand-held operating mechanism 3 includes a housing 302 provided with a handle 301, and the housing 302 is provided with a handle for controlling the driving device. and the control button 303 of the heating device, the drive device is provided with a torque sensor for detecting the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com