Dual spiral heating wire drawing machine added with underactuation stirring structure

A double-helix, under-actuated technology, applied in the field of 3D printing consumables production, can solve the problems of inaccurate temperature control and low drawing precision, and achieve the effects of avoiding uneven heating, accelerating melting efficiency, and reducing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

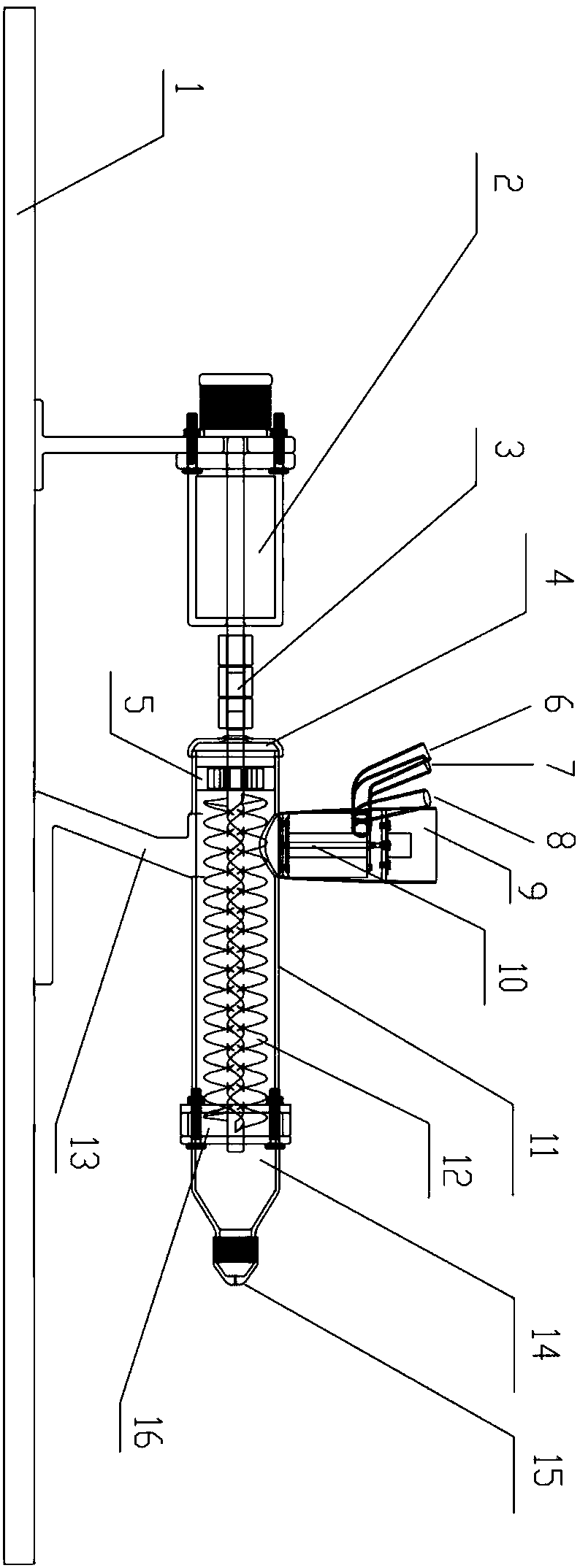

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

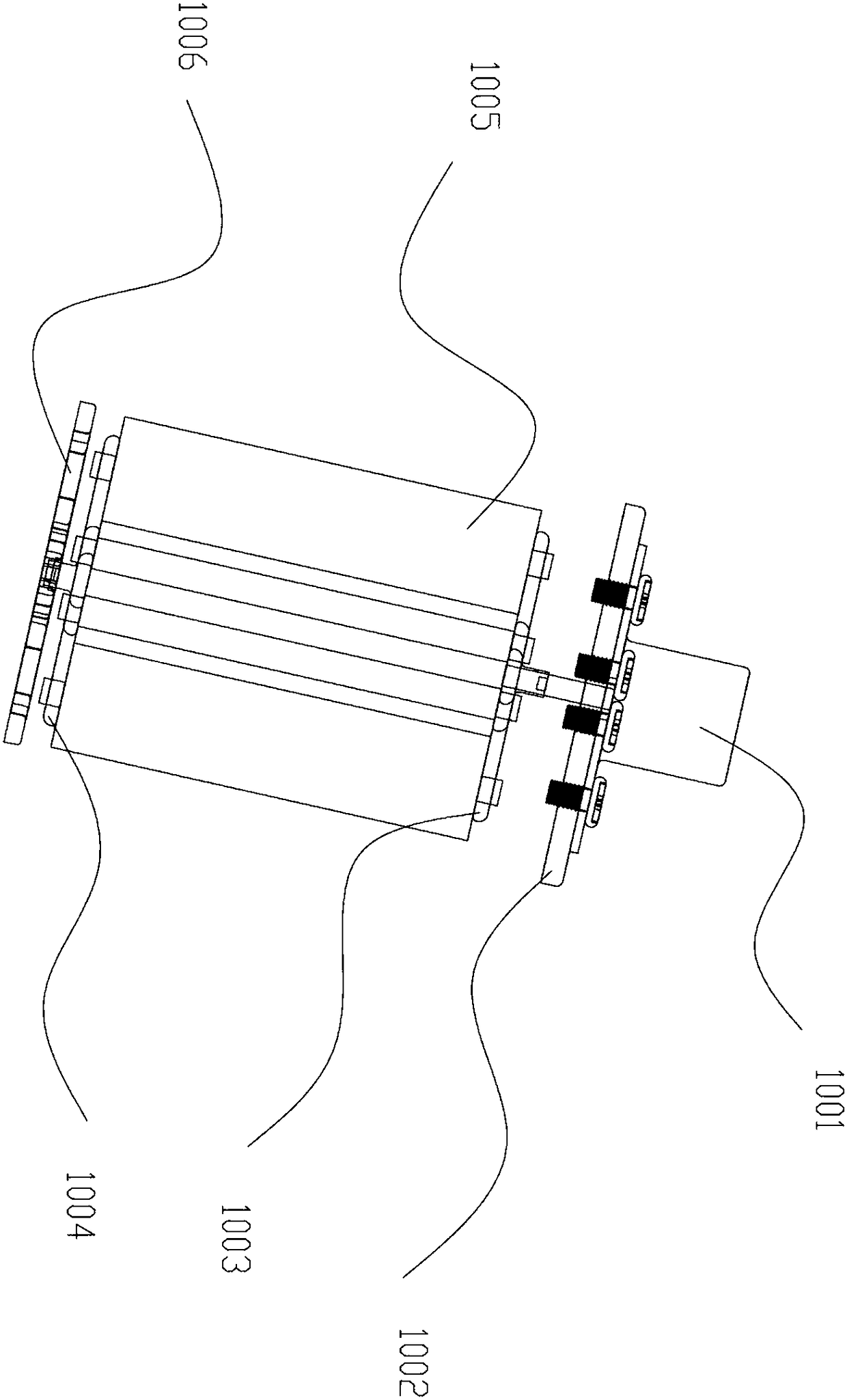

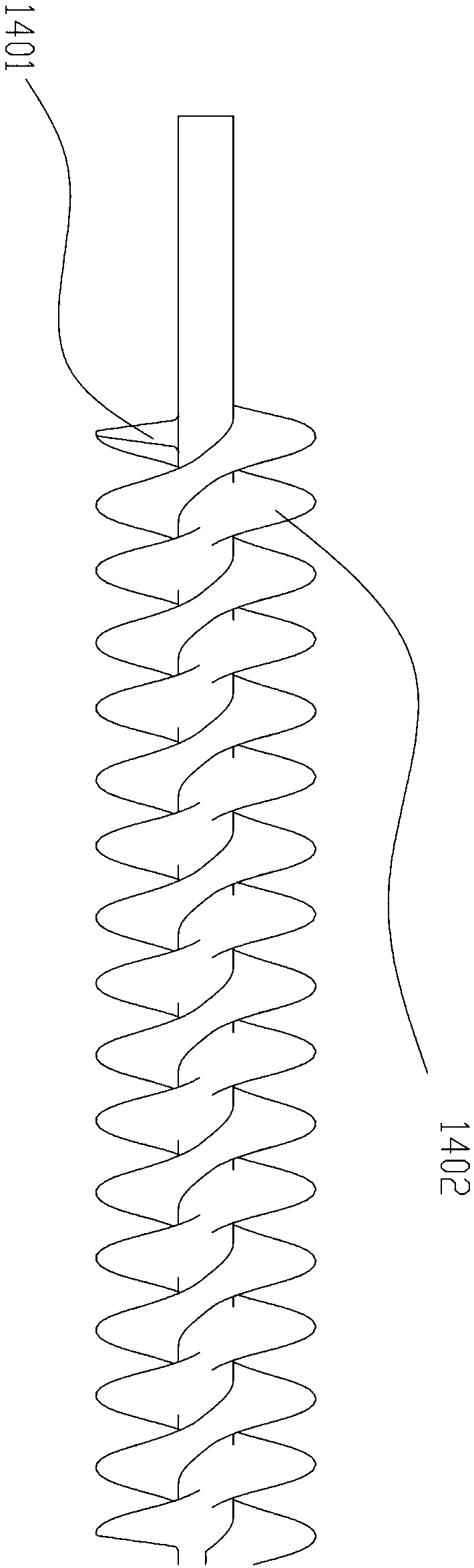

[0021] The support 13 and the motor 2 are fixed on the base 1, the double-helix heating screw 12 starts to preheat to the set temperature, and then the stirring structure 10 is under-driven to rotate. The plastic powder enters the hopper 9 through the feed port 6 , the modifier passes through the feed port 7 , and the colorant enters the hopper 9 through the feed port 8 . The upper end of the under-driven stirring structure 10 is fixed in the hopper through the cover plate 1002 and the lower end through the sieve plate 1006. The motor 1001 of the under-driven stirring structure 10 drives the upper cross turntable 1003, the lower cross turntable 1004, and the diamond-shaped blade 1005 to mix powder, modifier, Colorant. After mixing evenly, it fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com