Processing production line for cinnabar artware

A technology for handicrafts and production lines, applied in the field of cinnabar handicraft processing production lines, can solve the problems of error-prone, expensive robotic arms, complicated control, etc., and achieve the effects of reducing equipment costs, reducing mechanical interference, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

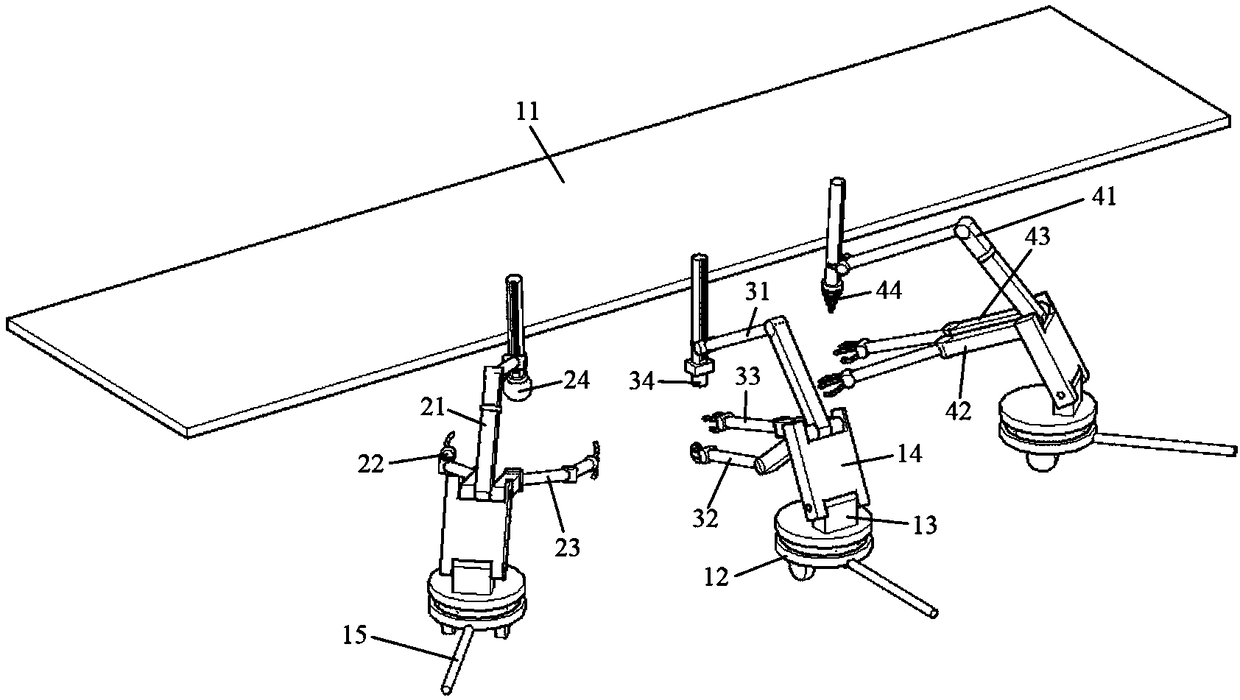

[0018] Such as figure 1 A kind of cinnabar handicraft processing production line shown, comprises conveyer belt 11; Described conveyer belt 11 side has three bases 12 to distribute along arc, and base 12 rear end is fixed with telescopic displacement rod 15, and the extension line of three telescopic displacement rods 15 intersects at three The central position of the arc distribution of two bases 12, the base 12 is fixed with a base 13; among the three bases 13, a base 13 upper end is arranged side by side successively to be rotatably fixed with the left arm 22 for beating, the middle arm 21 for beating, and the right arm for beating 23. The upper end of a base 13 is rotatably fixed in parallel with the left arm 32 for cutting, the middle arm 31 for cutting, and the right arm 33 for cutting. , drilling right arm 43; Base 12 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com