Tight clamping control device of air cylinder over-positioning

A control device and over-positioning technology, applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve problems affecting the accuracy of equipment operation, inaccurate rocker arm positioning, and unsatisfactory structures, etc., to achieve extended use Long life, solution to clamping deviation, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

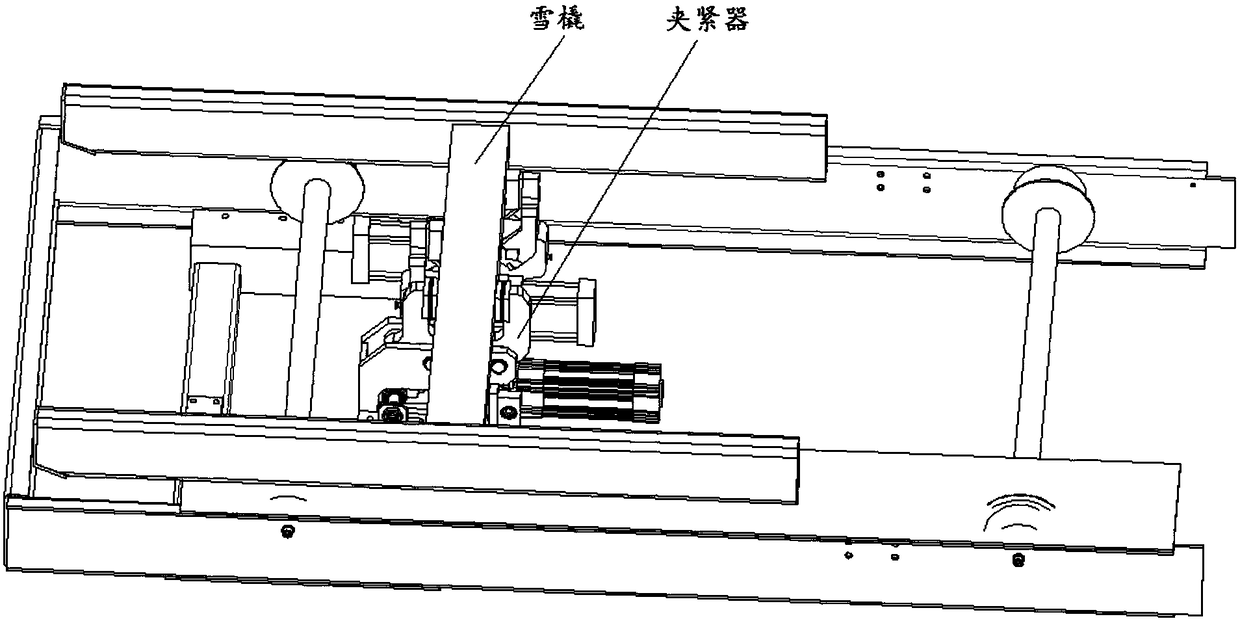

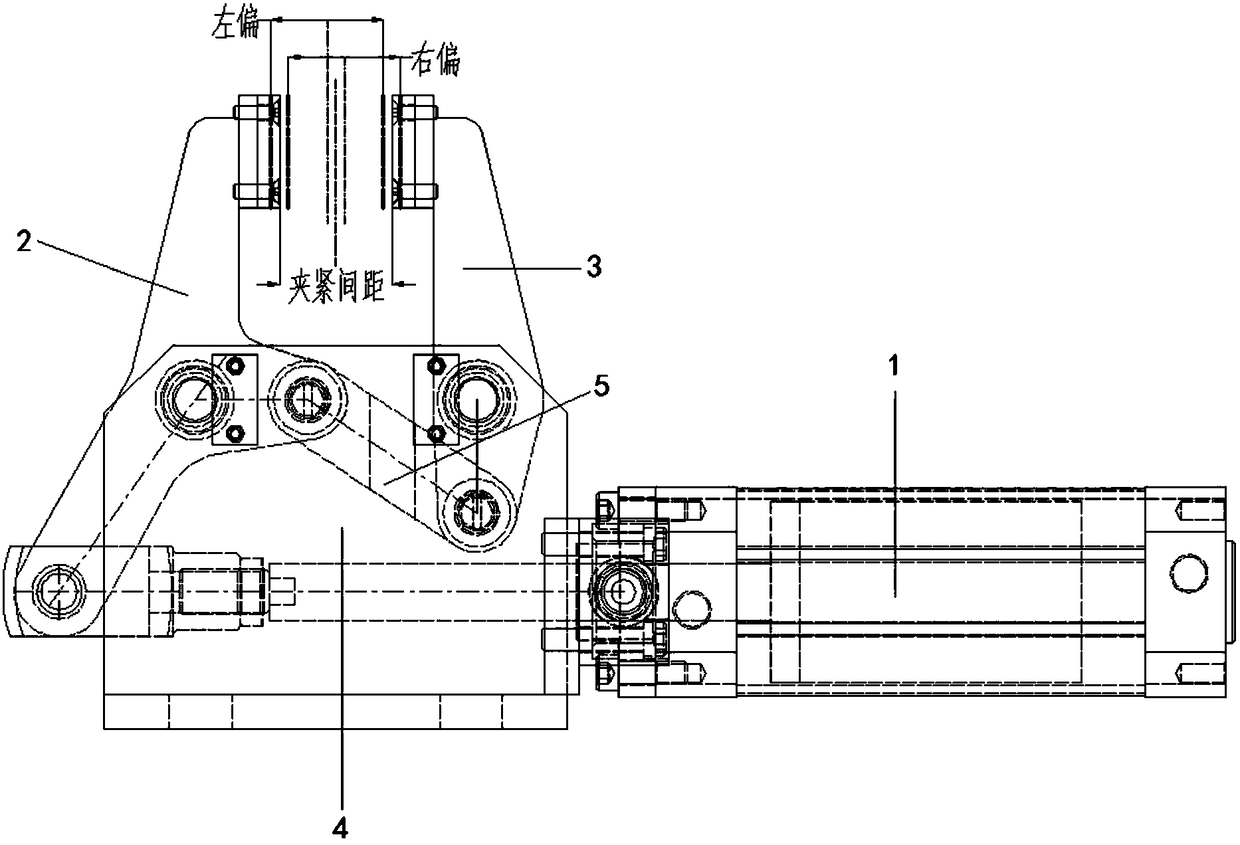

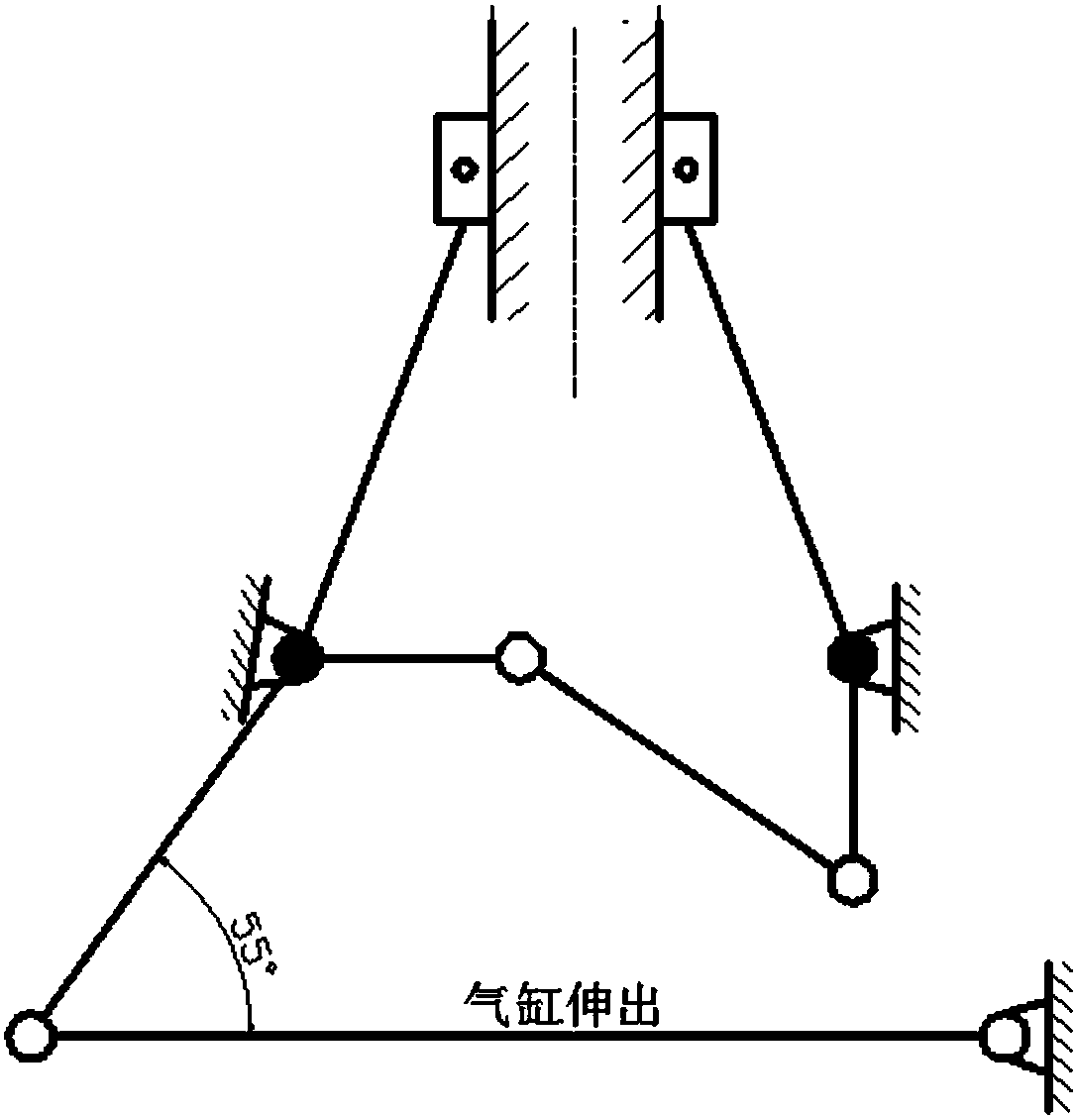

[0040] A cylinder over-positioning clamping control device, refer to the attached Figure 4-11 , comprising a base plate 7, a cylinder 1 located on one side of the base plate 7, and a clamping mechanism located on the upper part of the base plate 7, the clamping mechanism includes a rocker arm 2 and a cantilever arm 3, and the upper ends of the rocker arm 2 and the cantilever arm 3 are provided with a clamp assembly 6 , the upper part of the base plate 7 is vertically provided with two support plates, the rocker arm 2 and the cantilever 3 are arranged on the two support plates 4 through the shaft and the bearing assembly and are in the middle of the two support plates 4, and the rocker arm 2 and the cantilever 3 pass through a single lug The connecting rod 5 is hinged, and a sliding connection mechanism is provided between the output shaft of the cylinder 1 and the rocker arm 2. The sliding connection mechanism includes a double ear connecting rod 8, a pair of balance bearings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com