Elevator steel cable tension detecting and regulating device

A technology of adjusting device and wire rope, applied in the field of elevator, can solve the problems of inconvenience of carrying, inability to actually measure the tension force of wire rope, complicated device, etc., and achieve the effects of convenient operation, simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

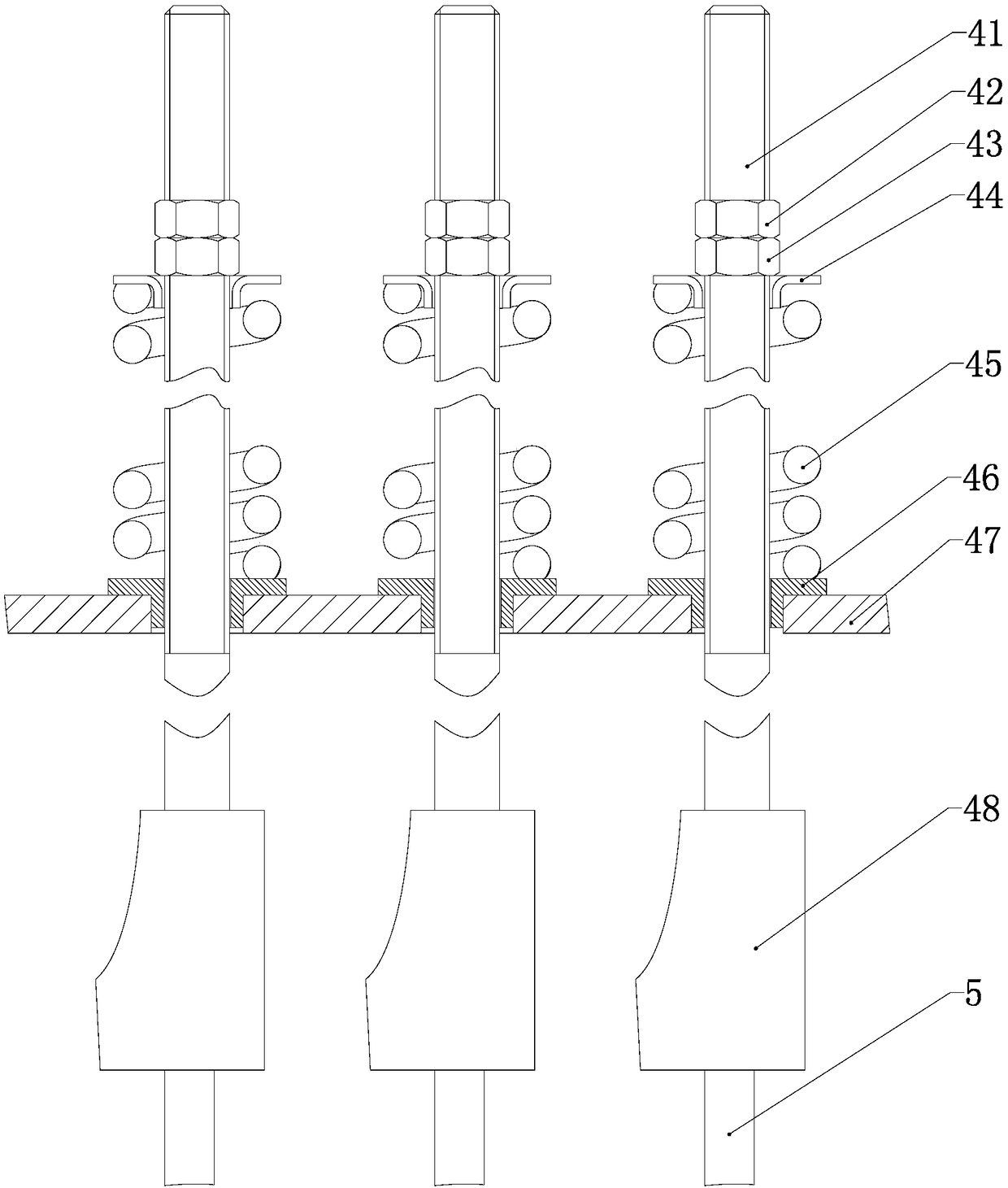

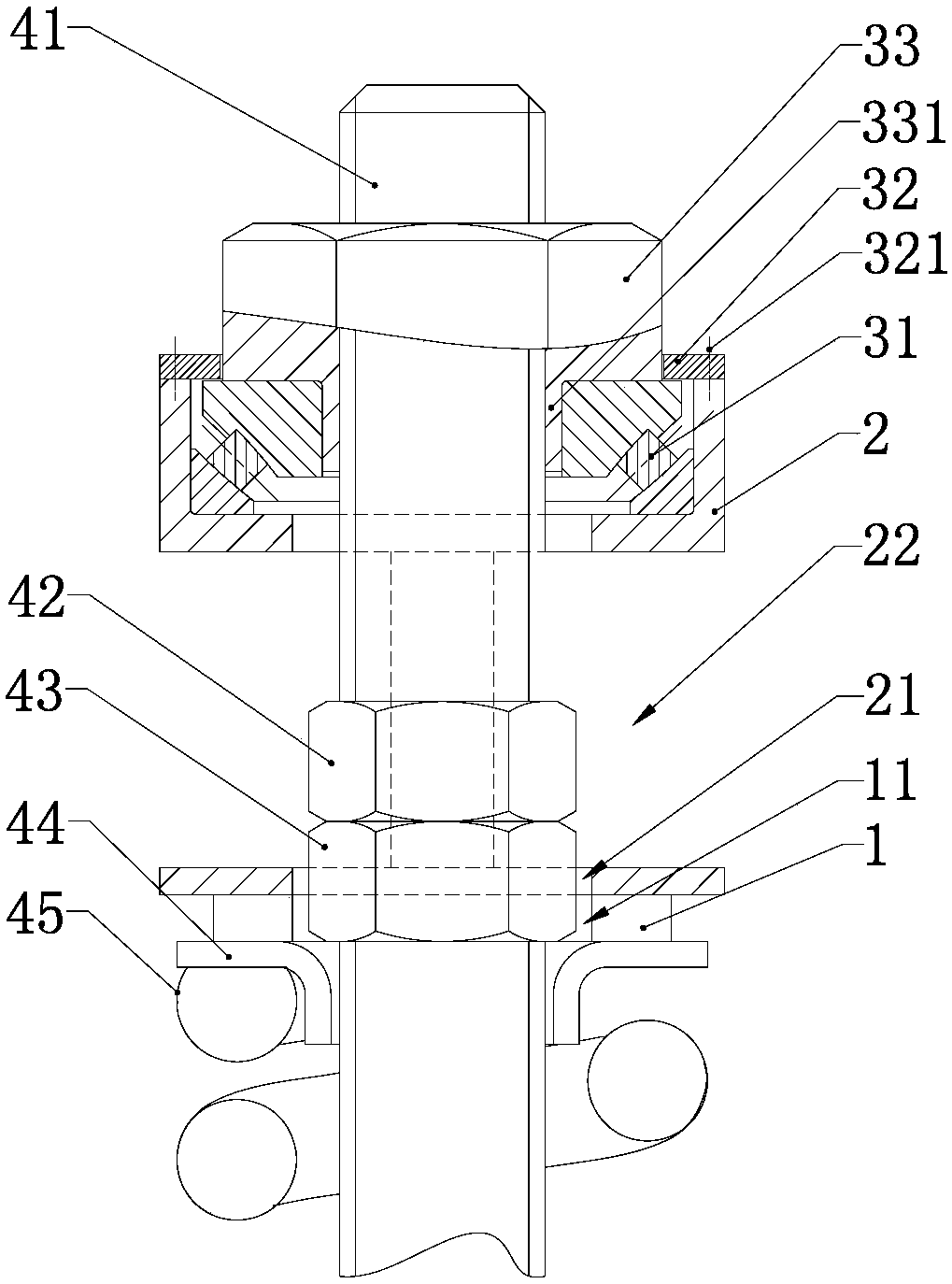

[0028] like Figure 2 to Figure 4 As shown, an elevator wire rope tension detection and adjustment device according to the present invention is mainly composed of a pressure sensor 1, a pressure sleeve 2 and a pressure sleeve displacement adjustment assembly.

[0029] The central part of the pressure sensor 1 is provided with a through hole 11 . The pressure sensor 1 is slidably sleeved on the pull rod 41 through the through hole, and its lower end surface fits on the upper end surface of the spring upper seat 44 . The diameter of the perforation 11 should be greater than the maximum dimension of the outer diameters of the locking nut 42 and the tightening nut 43 . In addition, the pressure sensor can be a wireless pressure sensor with a built-in wireless transmission module of the battery box, and a handheld mobile terminal for receiving and displaying pressure information is equipped corresponding to the wireless pressure sensor. The pressure sensor can also be a wired pre...

Embodiment 2

[0037] like Figure 5 to Figure 7 As shown, an elevator wire rope tension detection and adjustment device according to the present invention is mainly composed of a pressure sensor 1 , a pressure sleeve 2 , a pressure sleeve displacement adjustment assembly and a control device 36 .

[0038] The central part of the pressure sensor 1 is provided with a through hole 11 . The pressure sensor 1 is slidably sleeved on the pull rod 41 through the through hole, and its lower end surface fits on the upper end surface of the spring upper seat 44 . The diameter of the perforation 11 should be greater than the maximum dimension of the outer diameters of the locking nut 42 and the tightening nut 43 .

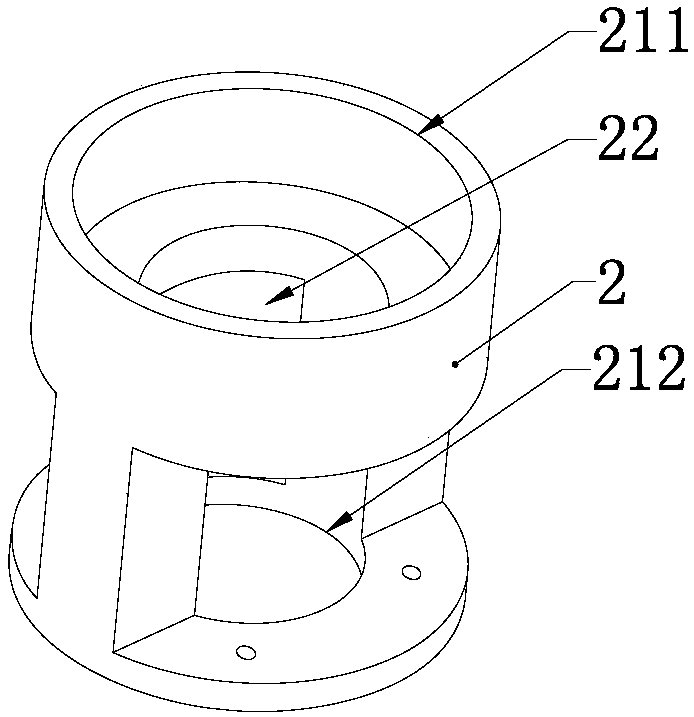

[0039] The pressure sleeve 2 is as image 3 As shown, it is cylindrical, and an axial through hole 21 is opened on it. The pressure sleeve is slidably sleeved on the pull rod 41 through the axial through hole, and its lower end surface is attached to the upper end surface of the pressure ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap