Semi-mechanical equipment for welding cup handle with cup body of glass cup and using method thereof

A welding equipment and glass technology, applied in glass manufacturing equipment, glass molding, glass re-molding, etc., can solve the problems of scrap glass, lack of positioning parts, dislocation and tilt of the cup handle and the cup body, etc. The effect of easy offset and firm welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

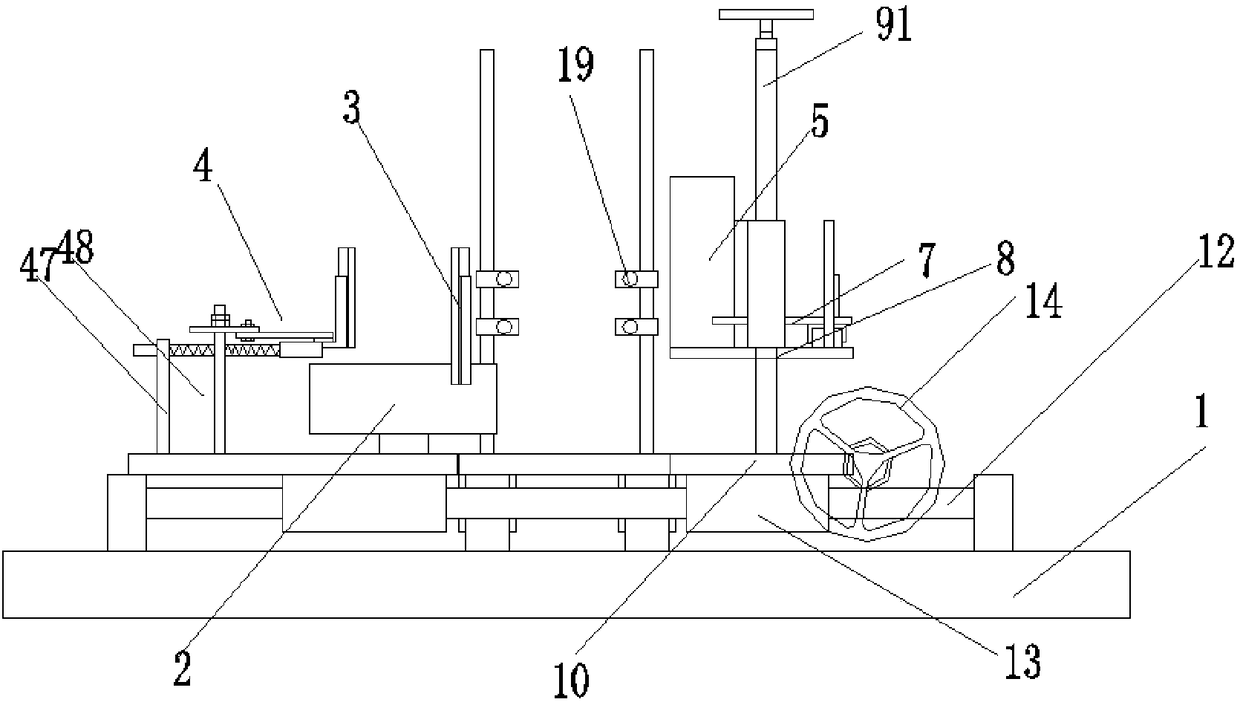

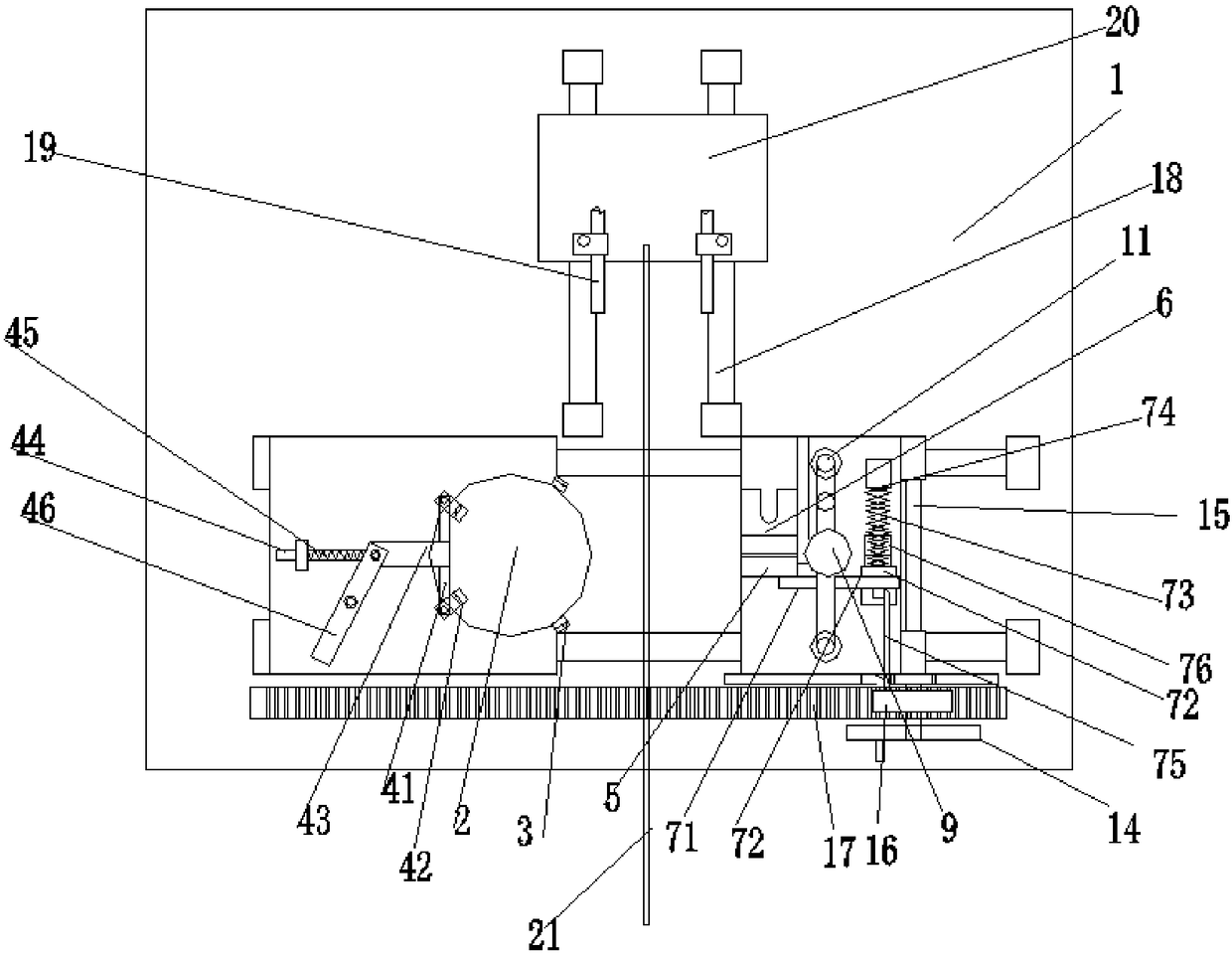

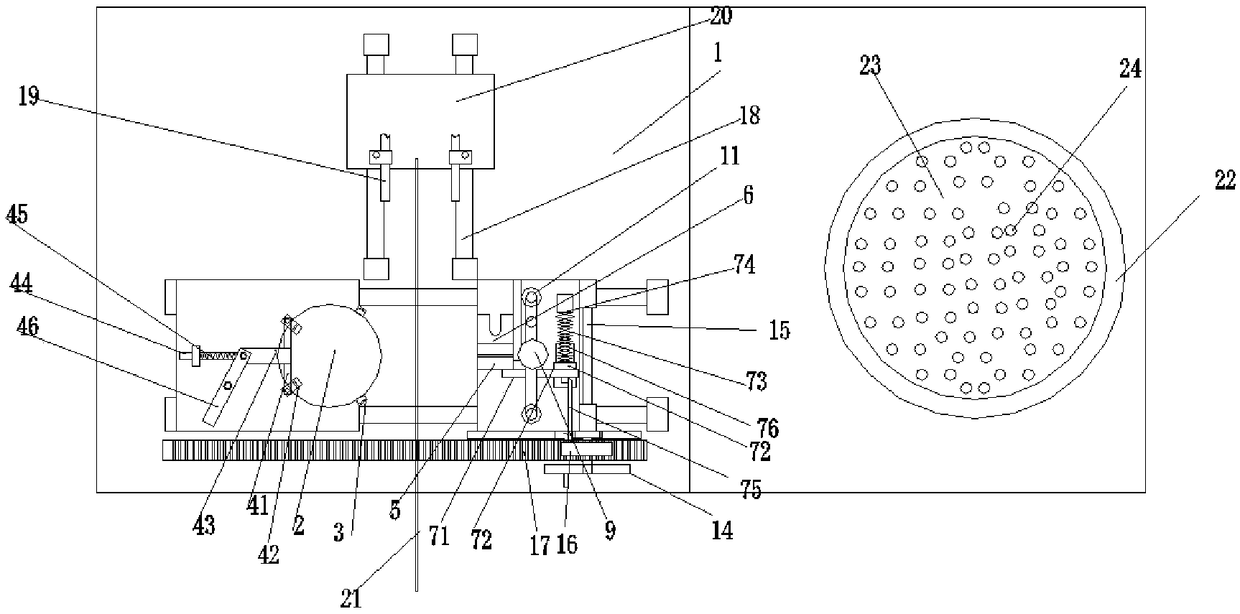

[0031] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

[0032] Semi-mechanized welding equipment for welding the handle and the cup body of a glass cup. The welding equipment includes a working platform 1. The working platform 1 is equipped with a cup body fixing device and a cup handle fixing device. The cup body fixing device includes a placing table for placing the cup body 2. On the side of the upper end of the placing table 2, there is a side bar 3 for limiting the position of the cup body. The cup handle fixing device includes a clamping mechanism arranged on the working platform 1. The clamping mechanism includes a clamping platform 8. When clamping Platform 8 is provided with fixed clamp block 6, and fixed clamp block 6 is provided with movable clamp block 5 oppositely; The relative position between the clamping blocks 6; in the present ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap