Imitated bamboo recombinant bamboo column and preparation method thereof

A bamboo column and imitation bamboo technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of insufficient utilization of material strength, increase of structural self-weight, splitting of hollow columns, etc., achieve the combination of beauty and practicality, and improve the bearing capacity Ability, perfect combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

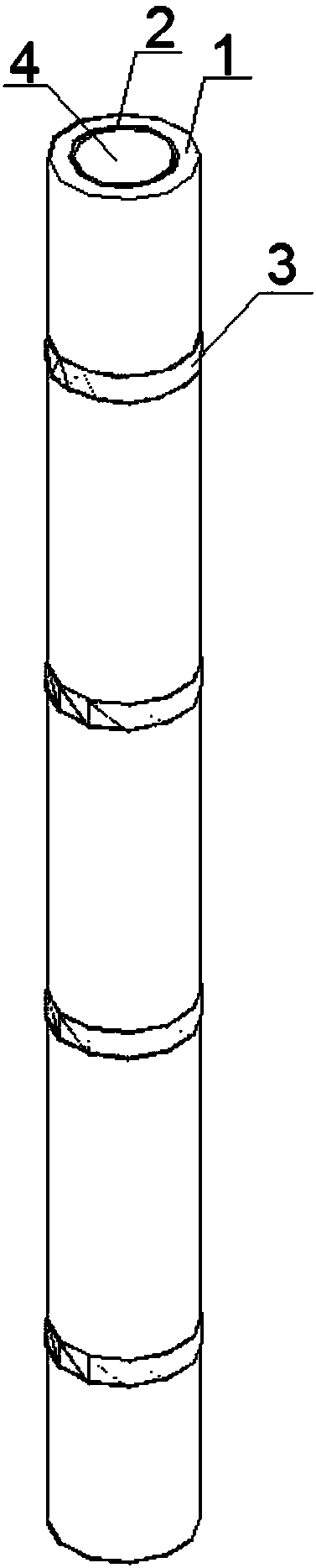

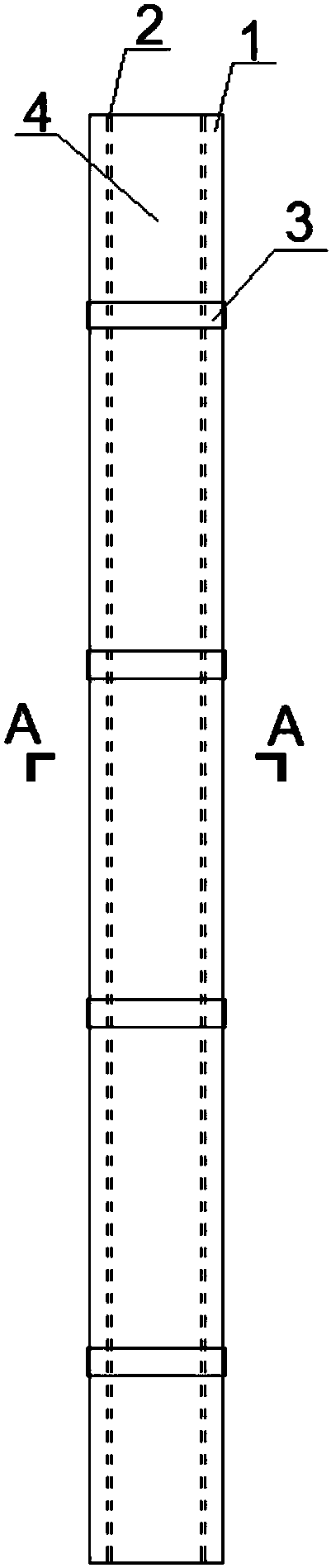

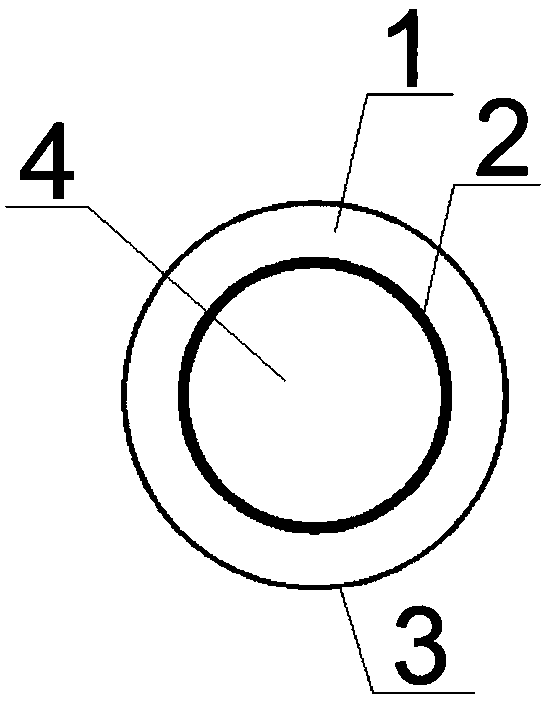

[0023] A bamboo imitation recombined bamboo column, comprising a restructured bamboo column tube 1, a built-in tube 2, and an outsourcing FRP reinforcement belt 3; The outside of the restructured bamboo column tube 1 is wrapped and strengthened with FRP reinforcement tape 3 at every interval length, and the FRP reinforcement tape 3 is pasted and connected with the restructured bamboo column tube 1 .

[0024] In this embodiment, the built-in tube 2 is made of metal.

[0025] In this embodiment, the built-in tube 2 is an inner mold for making the recombined bamboo column tube 1 .

[0026] In this example, see Figure 1-2 , the ratio of the diameter, wall thickness, and spacing between adjacent FRP reinforcement strips of the recombined bamboo column tube 1 is similar to that of natural bamboo.

[0027] In this embodiment, the bamboo-like recombined bamboo column is directly used as a supporting column of a building.

[0028] During the specific production, the following steps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com