A shrinkable segment for demolition inside a tunnel and its construction method

A technology of shrinking tubes and tunnels, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as waste, damage, and lack of solutions, and achieve the effects of saving overall time, saving construction period, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

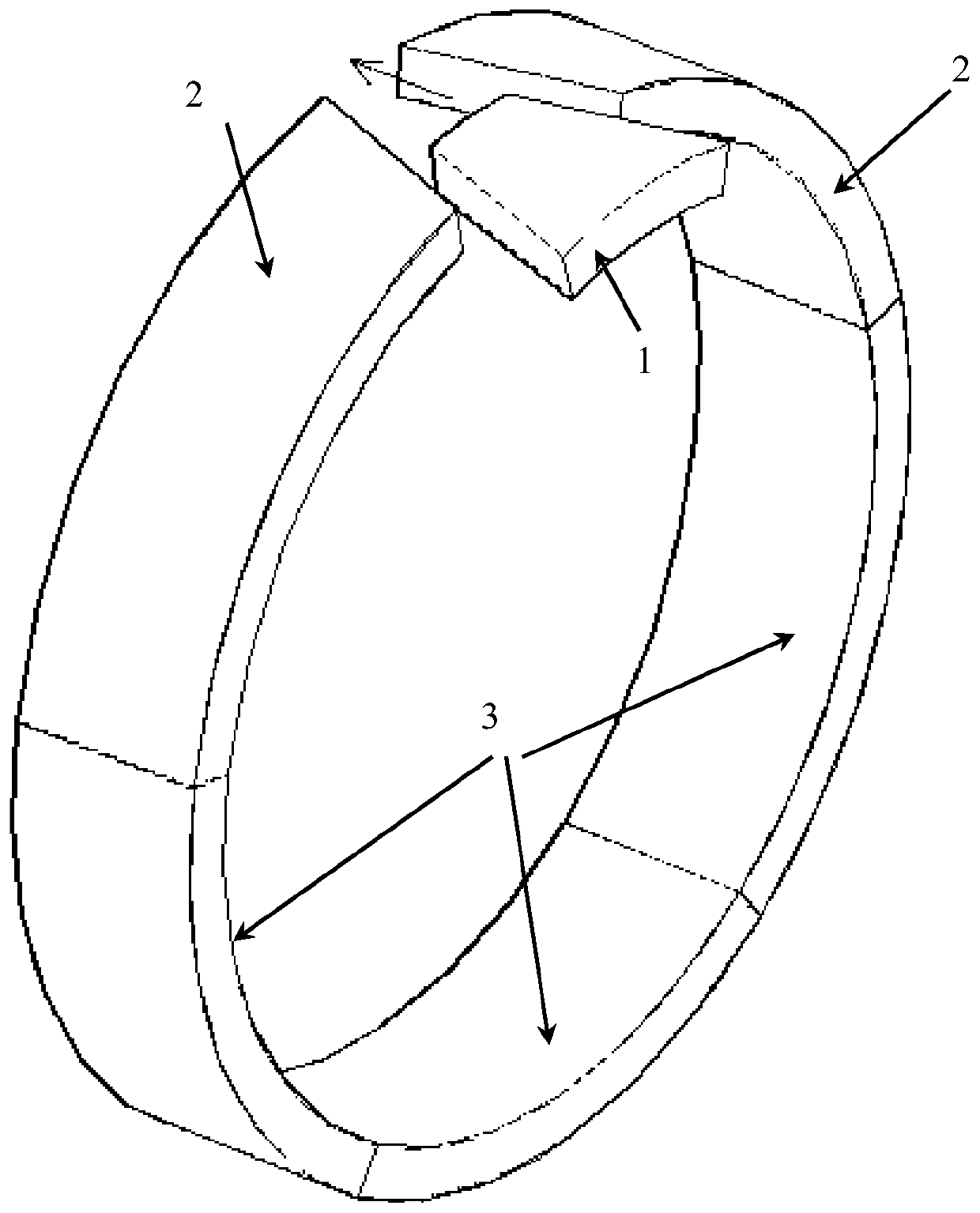

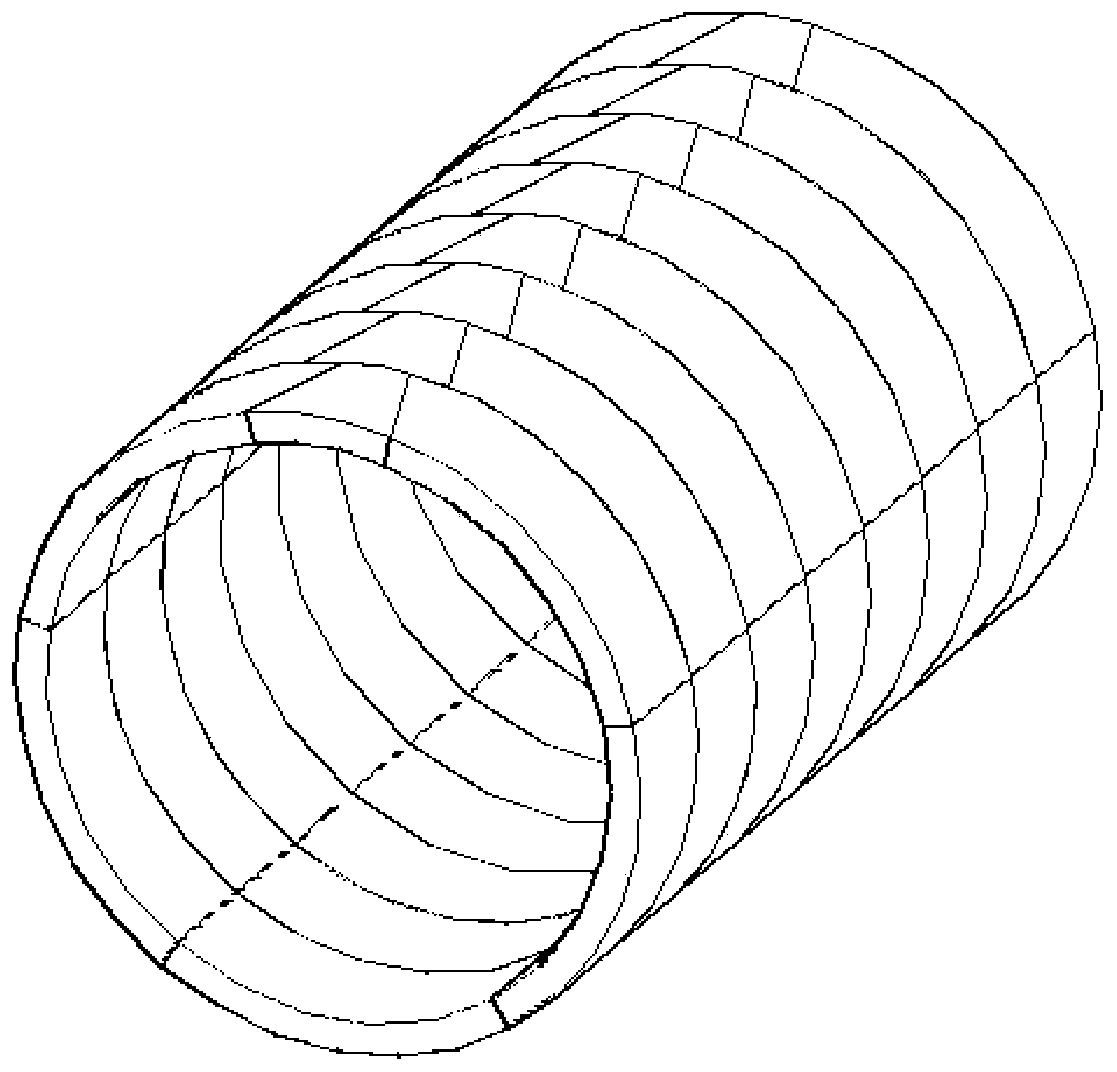

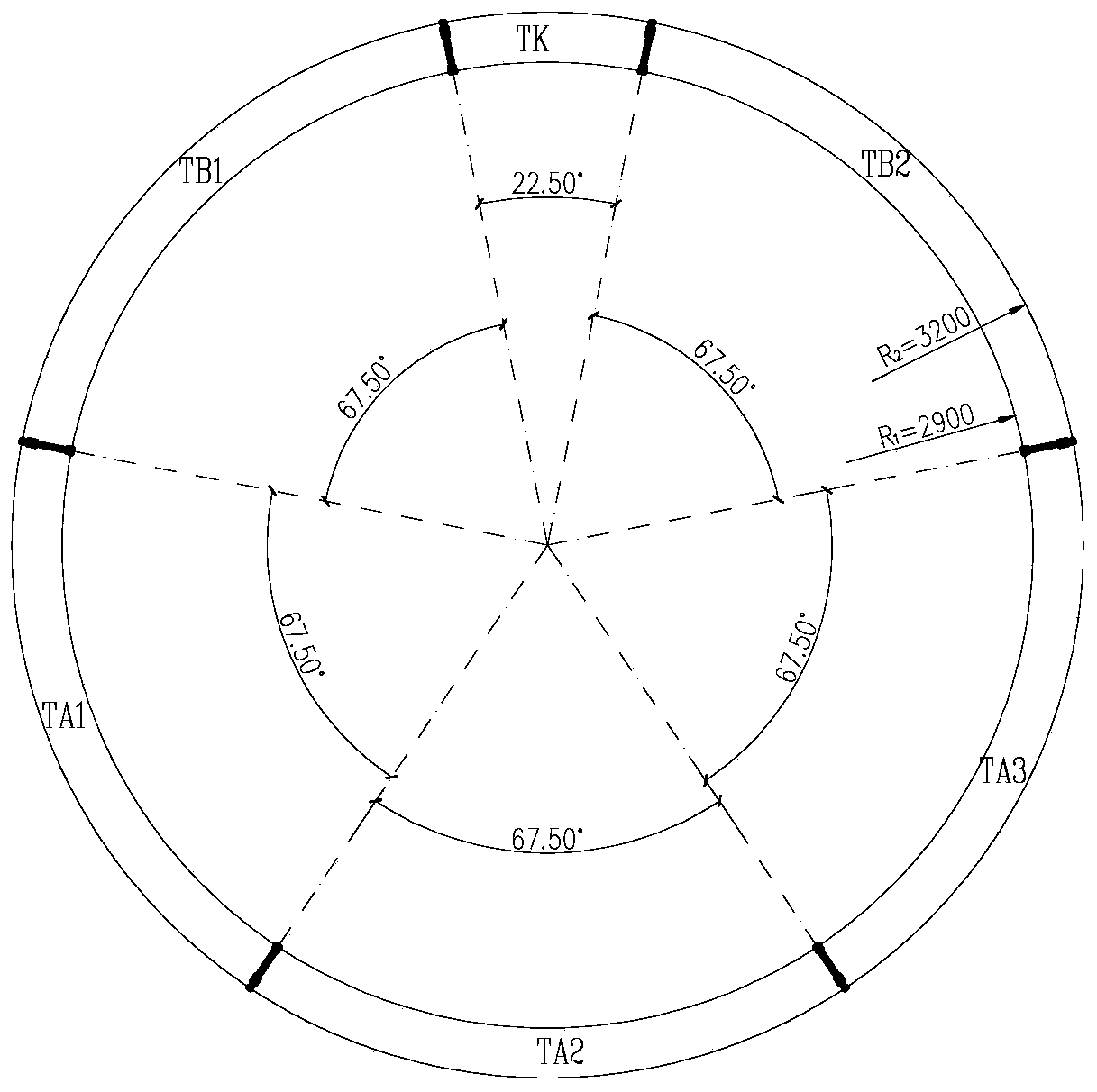

[0047] In a typical implementation of the present application, such as Figure 8-11 As shown, there is provided a shrinkable segment for removal inside the tunnel, which includes a plurality of standard blocks 3 adjacent to and around an arc-shaped structure. Both ends of the arc-shaped structure are close to an adjacent block 2. A capping block 4 is arranged between them, and the standard block 3, the adjacent block 2 and the capping block 4 form a cylindrical structure;

[0048] There are movable wings 5 on both sides of the capping block 4, and a telescopic part 6 is arranged inside the capping block 4, and the telescopic part 6 is connected with the movable wing 5, and the telescopic part 6 can drive the movable flap 5 to rotate or move to push against the adjacent block 2 .

[0049] The segment of the present invention does not change the conventional method of assembling the conventional segment of the shield machine, and replaces the K concrete segment (capping block...

Embodiment 2

[0058] like Figure 12-14 As shown, in this embodiment, the movable wing plate 5 of this embodiment is no longer fixed to the capping block, and both ends of the movable wing plate 5 are suspended and nested in the side of the capping block 4, and the connection between the movable wing plate 5 and the screw rod 6-1 Fixed connection between.

[0059] There are multiple telescopic parts 6, and a plurality of telescopic parts 6 are arranged in parallel. The telescopic parts 6 are arc-shaped and parallel to the capping block 4. They are all arranged radially along the capping block 4 . During the expansion and contraction process of the screw rod 6-1, the movable wing plate 5 expands outwards and moves along an arc, and then presses against the adjacent block after fitting with the end surface of the adjacent block.

[0060] Others are the same as in Example 1.

[0061] In another typical implementation of the present application, a construction method for a shrinkable segment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com