Heat insulation structure of brake disc

A technology of brake discs and heat insulation materials, which is applied in the field of vehicle engineering, can solve the problems of shortened service life, loss of lubricating oil burnout, and inability to perform lubrication, so as to prevent the working temperature from exceeding the standard, increase the tolerable temperature, Avoid the effect of heat conduction to

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

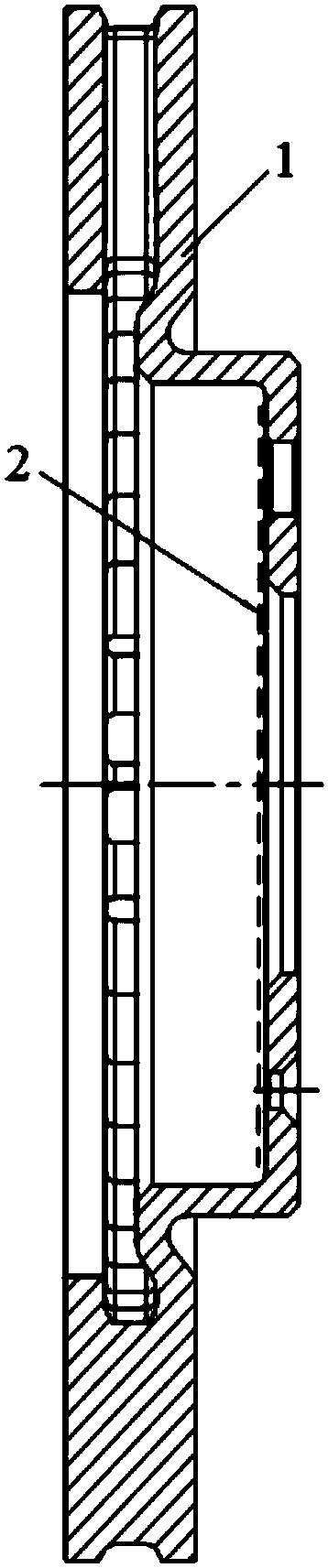

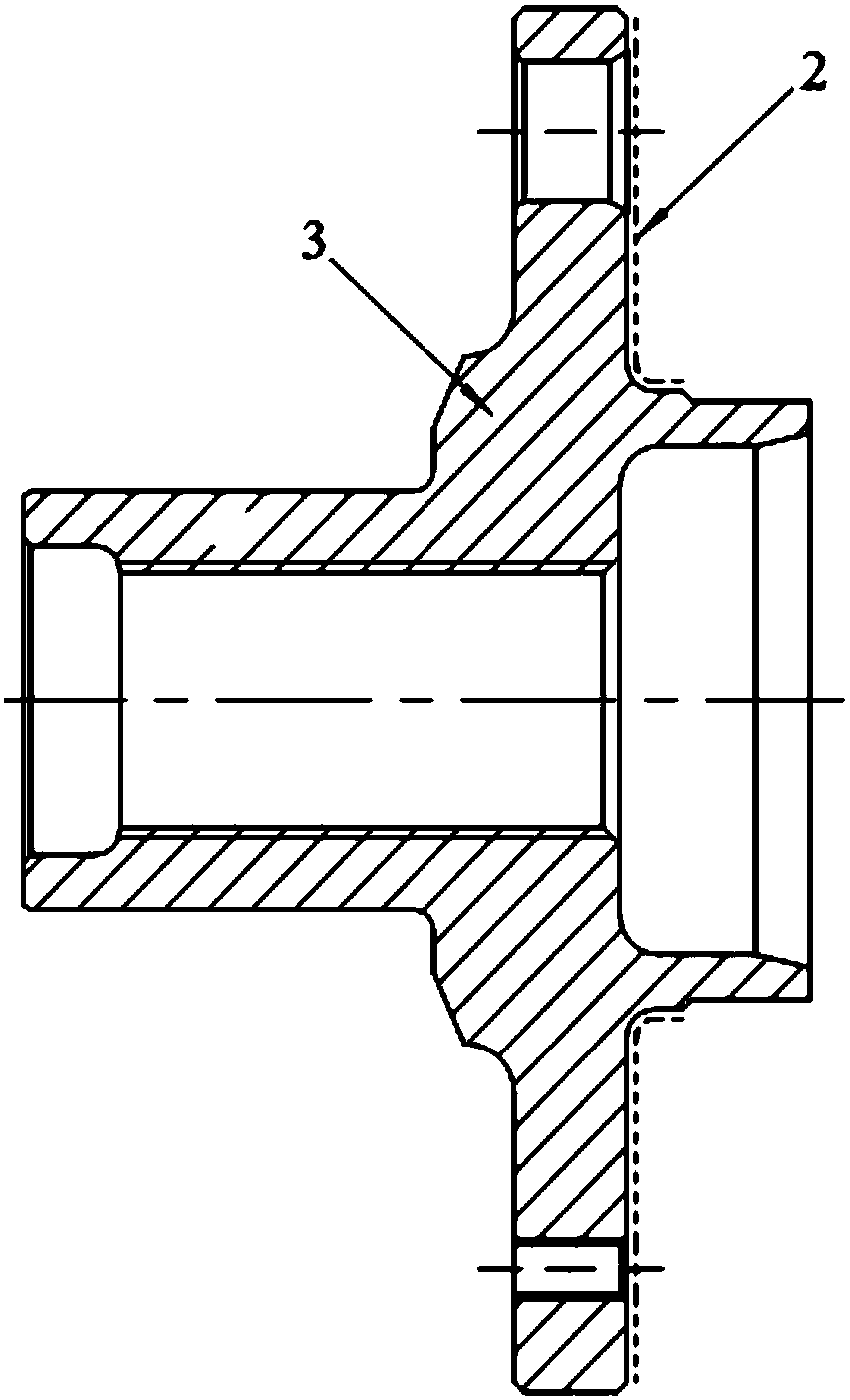

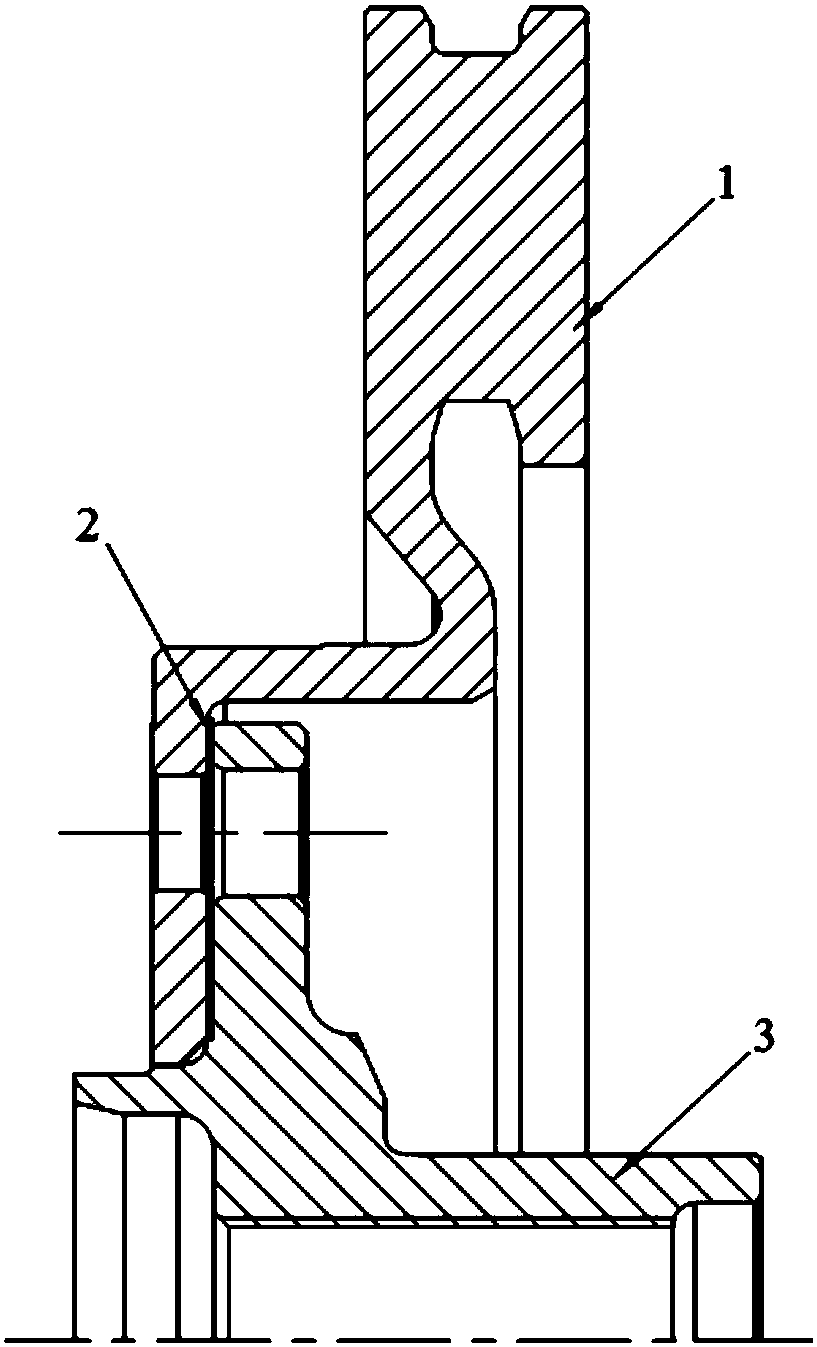

[0031] like Figure 1 to Figure 8 The structure of the present invention shown is a heat insulation structure of a brake disc, and the brake disc 1 is installed on the hub 3 .

[0032] In order to overcome the defects of the prior art and realize the purpose of preventing the heat transfer of the brake disc to the bearing, the technical solution adopted by the present invention is:

[0033] like figure 1 , figure 2 and image 3 As shown, in the heat insulation structure of the brake disc of the present invention, a heat insulation material 2 is provided between the end surface and the cylindrical surface of the brake disc 1 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com