Self-lubricating gear

A self-lubricating, gear technology, applied in the direction of engine lubrication, gear lubrication/cooling, belt/chain/gear, etc., can solve the problems of high noise, affecting the life of the gear, affecting the transmission of the two gears, etc., to ensure the strength and prolong the use. Longevity and the effect of preventing increased wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] refer to Figure 1 to Figure 3 The embodiment of a self-lubricating gear of the present invention will be further described.

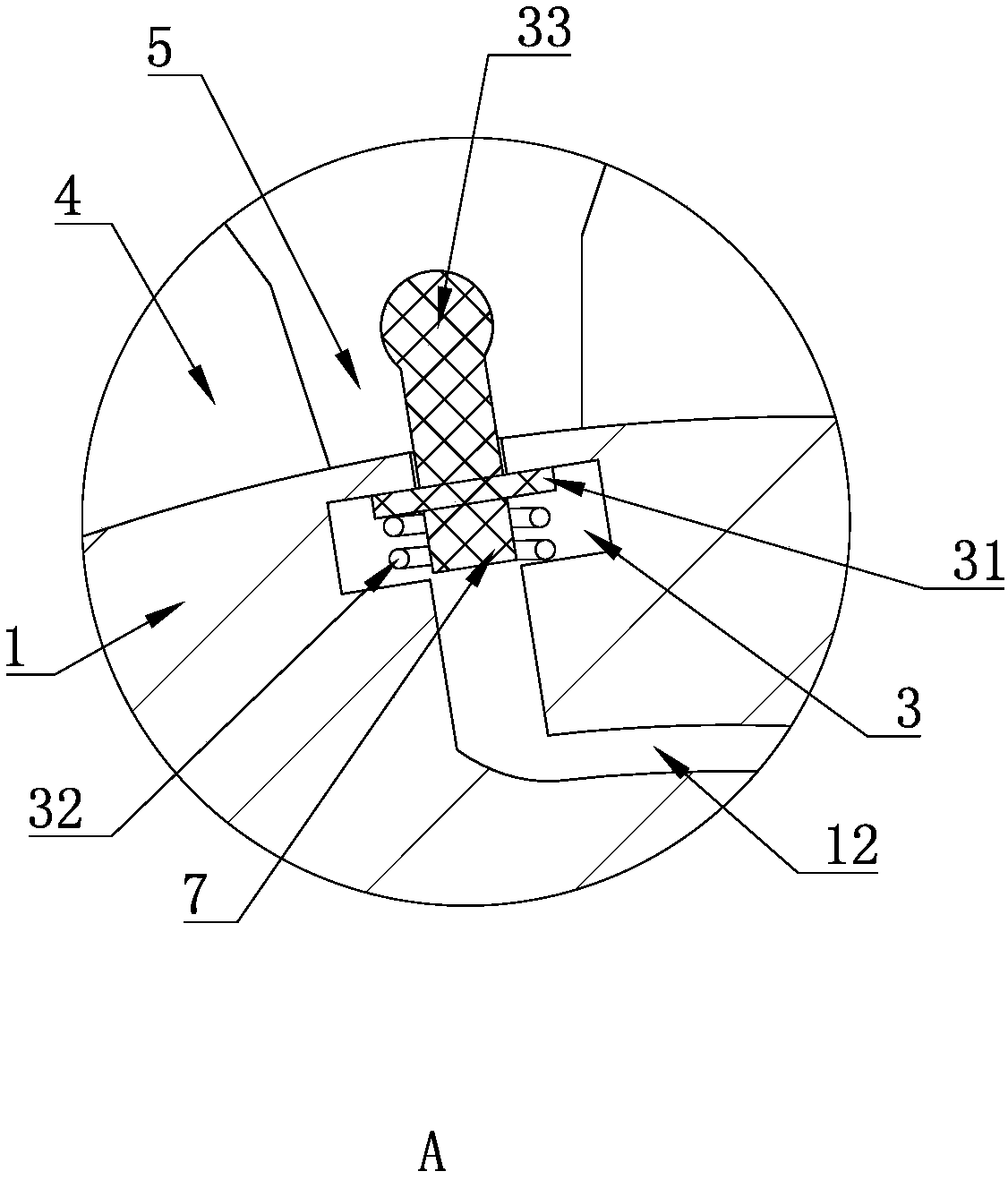

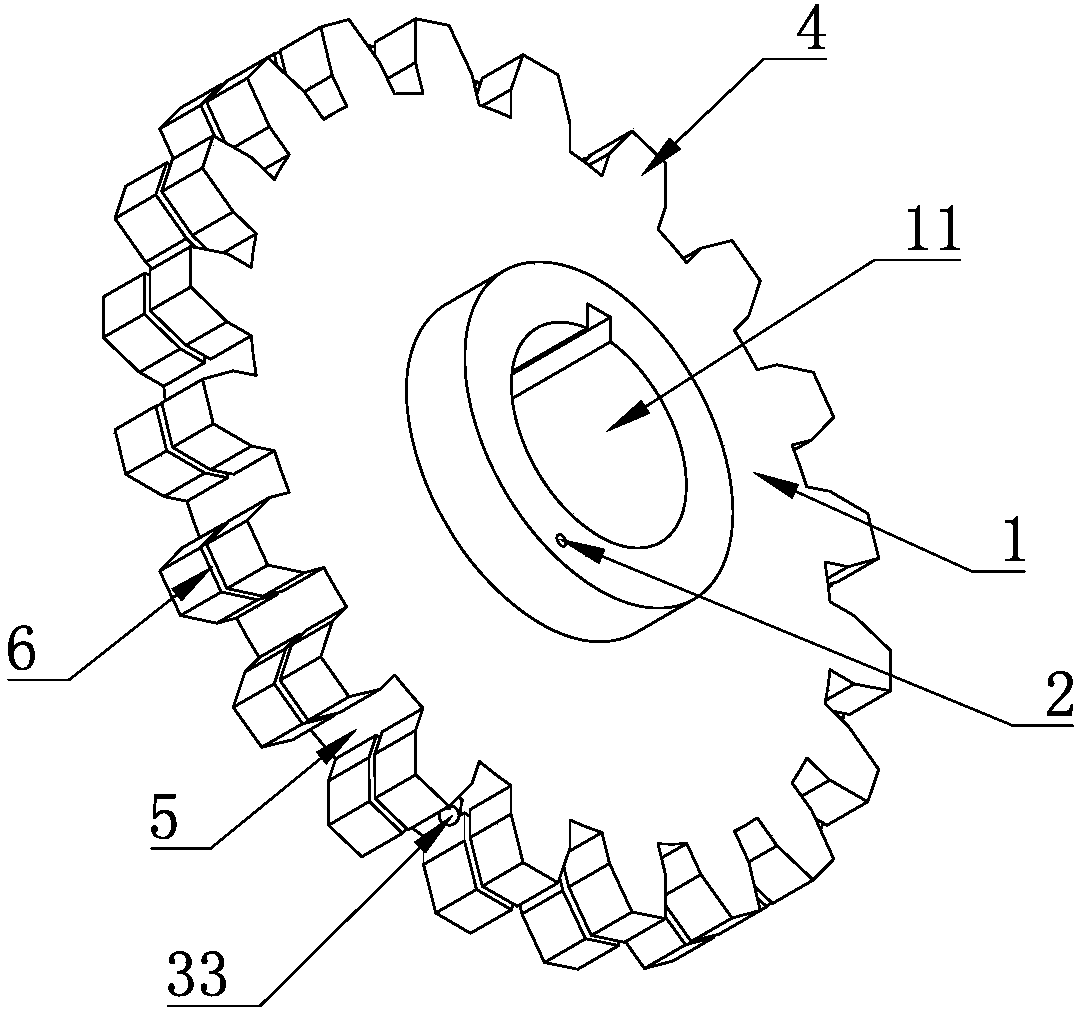

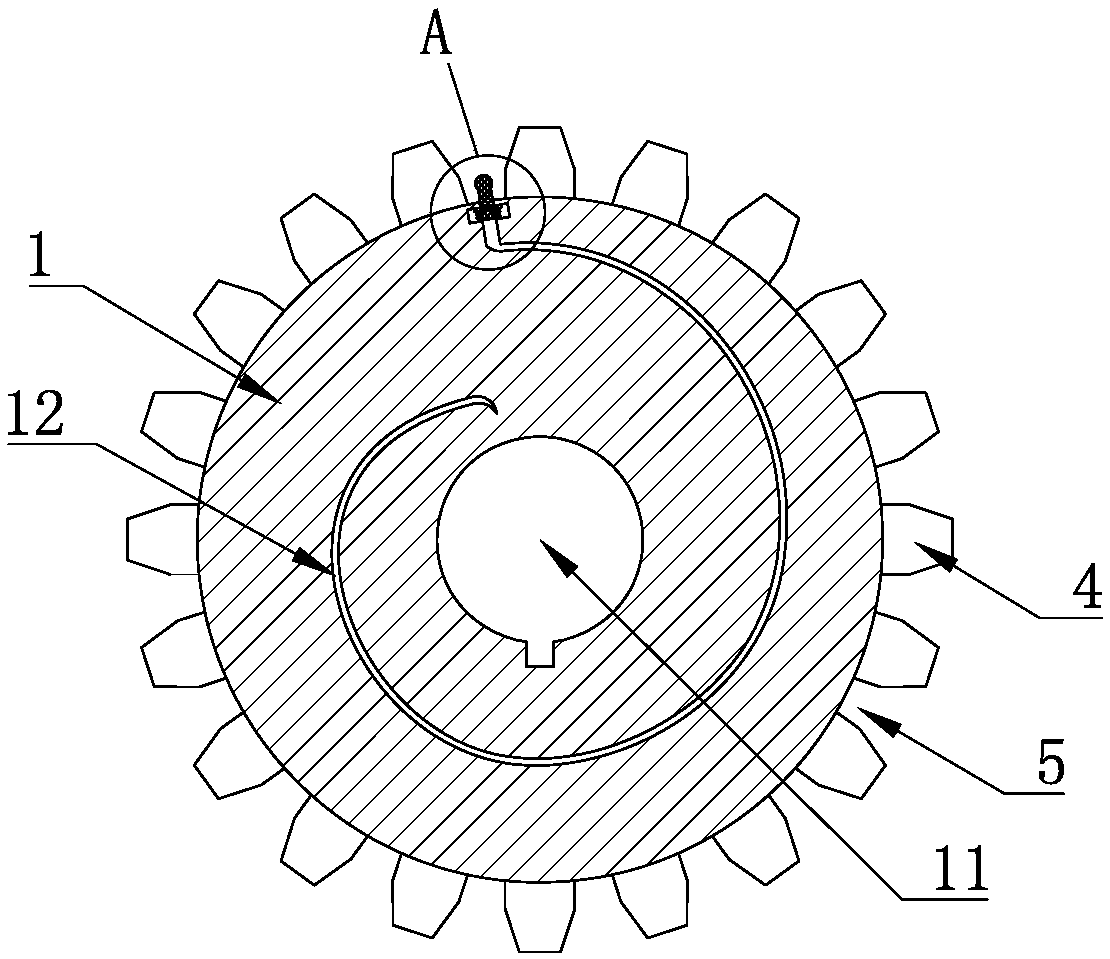

[0018] A self-lubricating gear, including a body 1 and gear teeth 4 surrounding the body 1, tooth slots 5 are formed between the teeth 4, the body 1 is provided with a mounting hole 11 for installing the gear, and the body 1 is provided with a volute The oil delivery channel 12, the oil injection hole 2 for injecting lubricating oil into the oil delivery channel 12, and the oil outlet hole 3 located on the tooth groove 5, one end of the vortex oil delivery channel 12 communicates with the oil injection hole 2, and the other end communicates with the tooth groove 5 , the oil filling hole 2 is provided with an oil filling plug, the oil outlet hole 3 is provided with a limiter 31 and a return spring 32, the return spring 32 pushes the limiter 31 to close the oil outlet 3, and the limiter 31 is connected with a tooth groove 5, the top of the push r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap