Whole plant temperature control and humidity control dust removal intelligent control system and method

An intelligent control system, temperature control and humidity control technology, applied in the direction of heating and ventilation control system, control input related to air characteristics, control input related to system status, etc., can solve the problems of complex operation and high maintenance cost, and achieve optimization The effect of operating parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

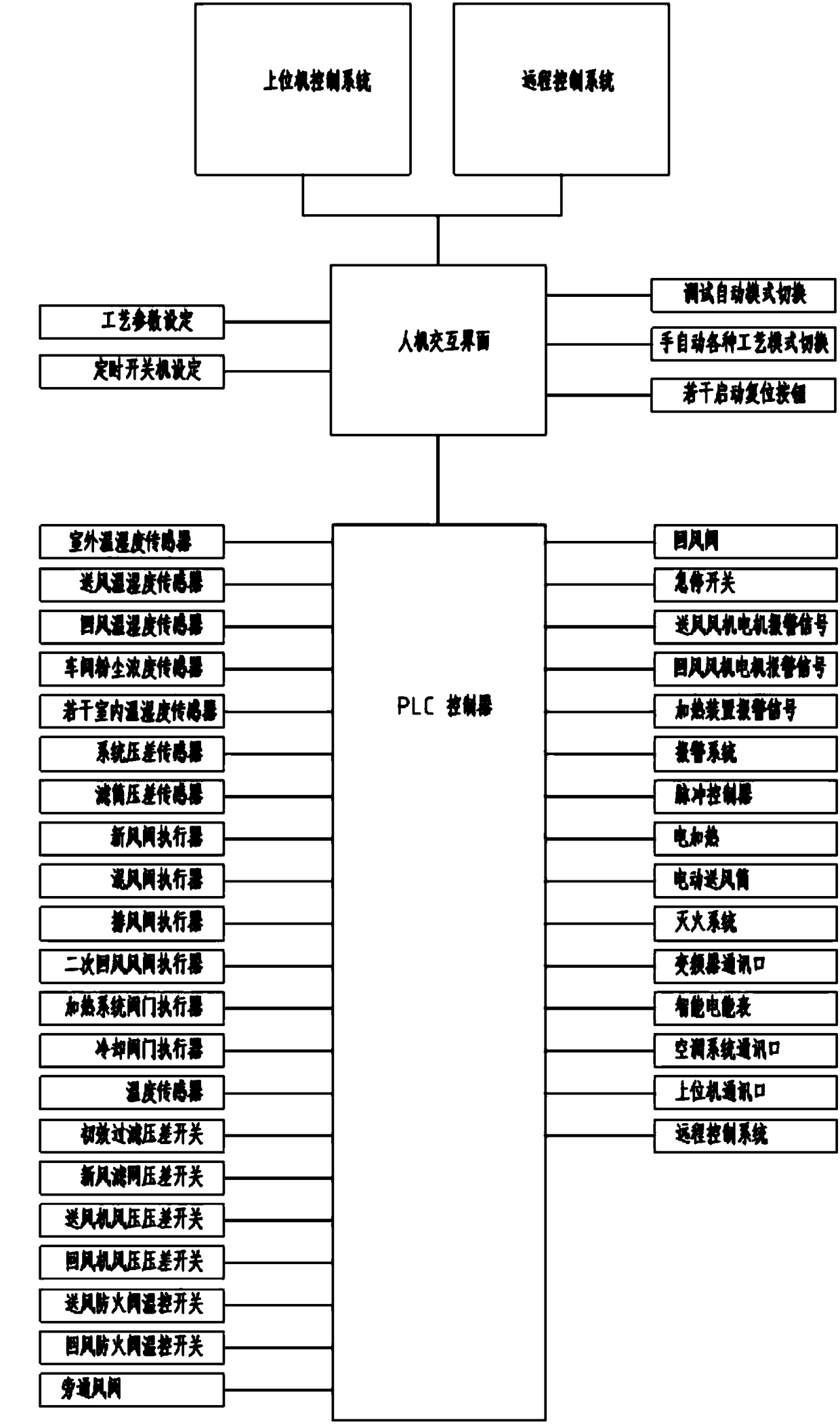

[0037] Such as figure 1 As shown, an intelligent control system for overall temperature control, humidity control, and dust removal of a factory building includes a remote control system, a host computer, and a PLC controller. Both the remote control system and the host computer are connected to the PLC controller, and the PLC controller is connected to the PLC controller. The components of the dust removal system arranged in the workshop are connected with the components of the air conditioning system, and the PLC controller is connected with the smart electric meter.

[0038] By reading the power consumption of smart meters, remote analysis of power consumption and combined with big data analysis, optimize operating parameters, provide users with optimal process parameters, and can modify process parameters online through user authorization to achieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com