Foamed ceramic production and processing system

A processing system and technology of foamed ceramics, which are applied in the drying of ceramic products, lighting and heating equipment, drying, etc., can solve the problems of high baking temperature, scrapped ceramic mud embryos, and cracks in the side walls of ceramic mud embryos.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

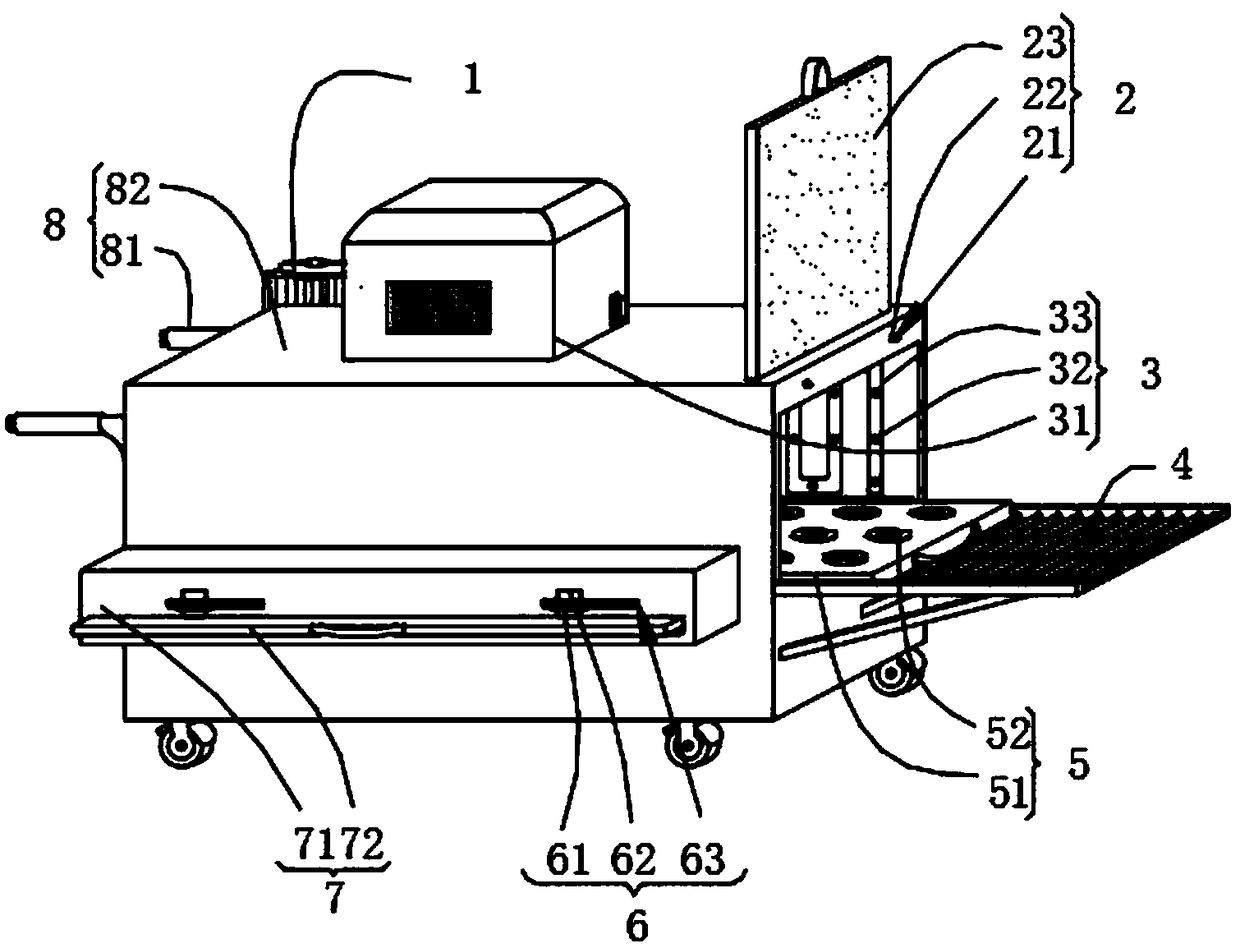

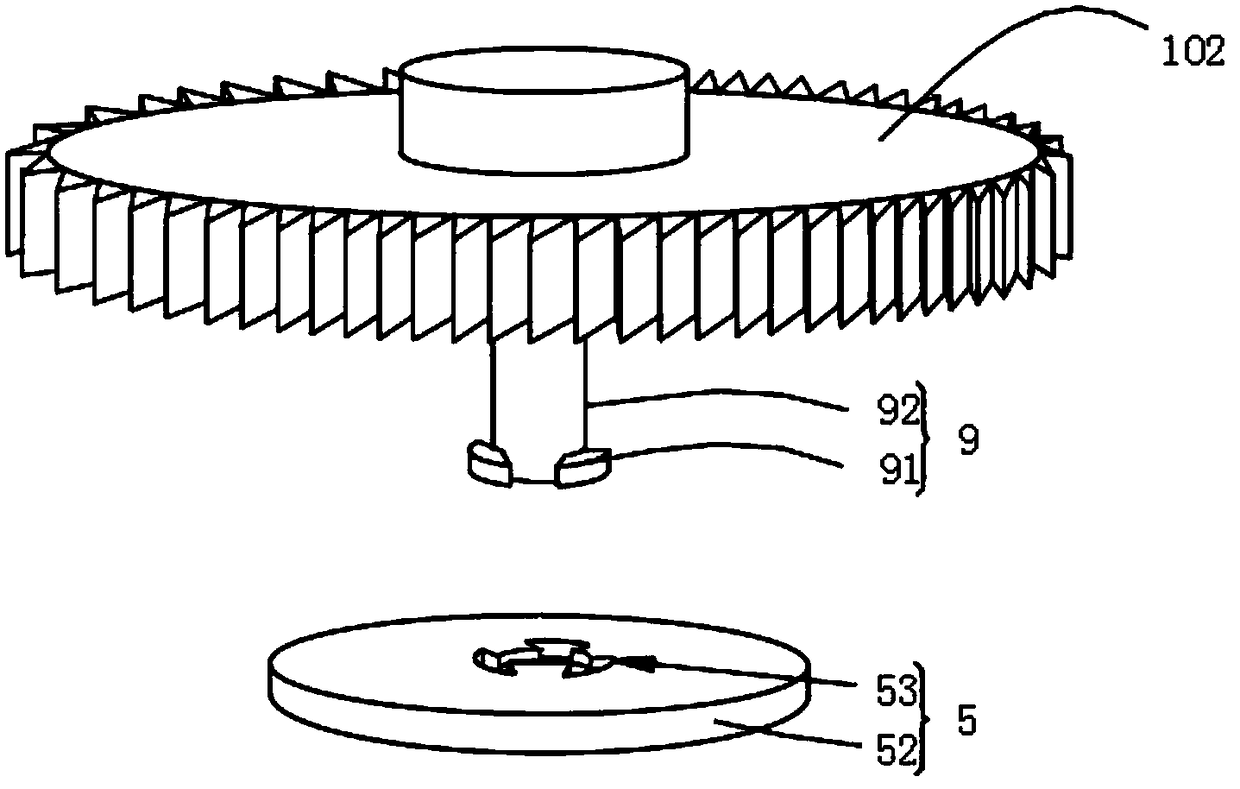

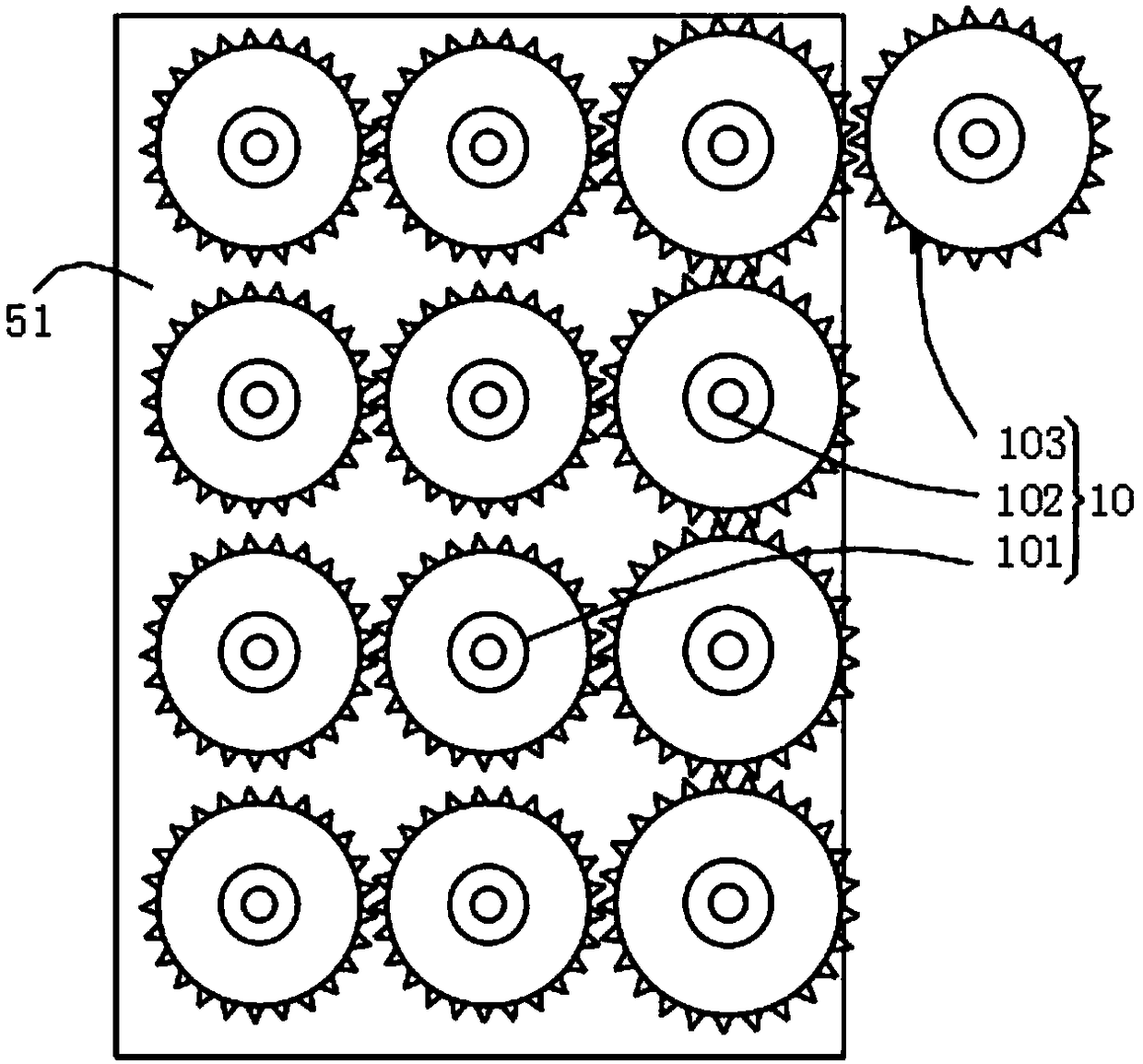

[0030] Such as figure 1As shown, a kind of ceramic foam production and processing system described in the present invention, the technical solution adopted by the present invention to solve its technical problems is: a kind of foam ceramic production and processing system, including motor 1, closing mechanism 2, air-drying mechanism 3, support Frame 4, fixing mechanism 5, limit mechanism 6, collection mechanism 7, storage mechanism 8, connecting mechanism 9 and rotating mechanism 10; One end side wall of described storage mechanism 8 is fixedly connected with described motor 1, and one end of described motor 1 The rotating mechanism 10 is fixedly connected; the support frame 4 is installed at one end of the storage mechanism 8; the storage mechani...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap