Treatment methods of radioactive waste oil

A radioactive waste treatment method technology, which is applied in the field of radioactive waste oil treatment, can solve the problems that it is not suitable for mass production, large-scale treatment of radioactive waste oil, that it cannot be formally treated with radioactive waste oil, and that it is difficult to treat the tail gas of the incineration method. Achieve the effect of reducing the possibility of radioactive leakage, reducing management risks and costs, and reducing fire hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

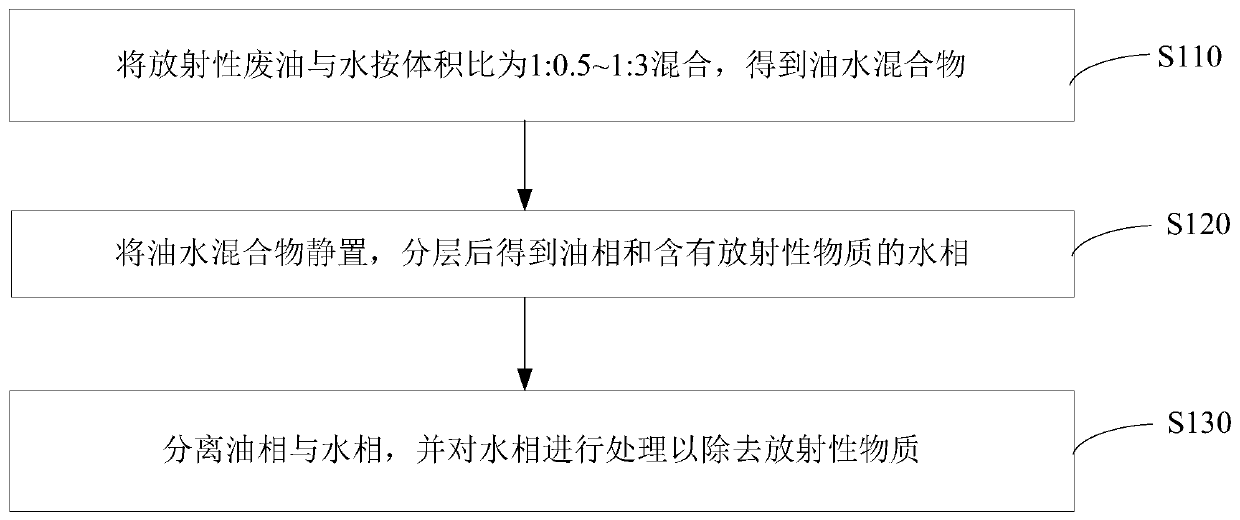

Method used

Image

Examples

Embodiment 1

[0063] The present embodiment is as follows to the processing method of radioactive waste oil:

[0064] The radioactive waste oil is taken from the No. 2 waste oil storage tank of the Daya Bay Nuclear Power Plant. The radioactive waste oil mainly comes from the lubricating oil and hydraulic oil used in the operation and maintenance of the relevant wearing equipment of the nuclear power plant. Transport the radioactive waste oil in the waste oil storage tank to the storage container through the peristaltic pump, transfer the storage container containing the radioactive waste oil to the vicinity of the reaction container, and then use the peristaltic pump to pump the radioactive waste oil in the storage container into the reaction container , The reaction vessel is equipped with a stirrer. Then use a peristaltic pump to add deionized water to the reaction vessel, wherein the radioactive waste oil in the reaction vessel is 2L, and the volume of deionized water is 1L. The mixture ...

Embodiment 2

[0066] The present embodiment is as follows to the processing method of radioactive waste oil:

[0067] The radioactive waste oil is taken from the No. 2 waste oil storage tank of the Daya Bay Nuclear Power Plant. The radioactive waste oil mainly comes from the lubricating oil and hydraulic oil used in the operation and maintenance of the relevant wearing equipment of the nuclear power plant. Transport the radioactive waste oil in the waste oil storage tank to the storage container through the peristaltic pump, transfer the storage container containing the radioactive waste oil to the vicinity of the reaction container, and then use the peristaltic pump to pump the radioactive waste oil in the storage container into the reaction container , The reaction vessel is equipped with a stirrer. Then use a peristaltic pump to add deionized water to the reaction vessel, wherein the radioactive waste oil in the reaction vessel is 1L, the volume of deionized water is 1L, and the mixture ...

Embodiment 3

[0069] The present embodiment is as follows to the processing method of radioactive waste oil:

[0070] The radioactive waste oil is taken from the No. 2 waste oil storage tank of the Daya Bay Nuclear Power Plant. The radioactive waste oil mainly comes from the lubricating oil and hydraulic oil used in the operation and maintenance of the relevant wearing equipment of the nuclear power plant. Transport the radioactive waste oil in the waste oil storage tank to the storage container through the peristaltic pump, transfer the storage container containing the radioactive waste oil to the vicinity of the reaction container, and then use the peristaltic pump to pump the radioactive waste oil in the storage container into the reaction container , The reaction vessel is equipped with a stirrer. Then use a peristaltic pump to add deionized water to the reaction vessel, wherein the radioactive waste oil in the reaction vessel is 1L, the volume of deionized water is 2L, and the mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com