Connection structure of cable and printed circuit board (PCB)

A PCB board and connection structure technology, which is applied in the direction of connection, fixed connection, and parts of the connection device, can solve problems such as errors, mutual signal crosstalk, and impedance instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

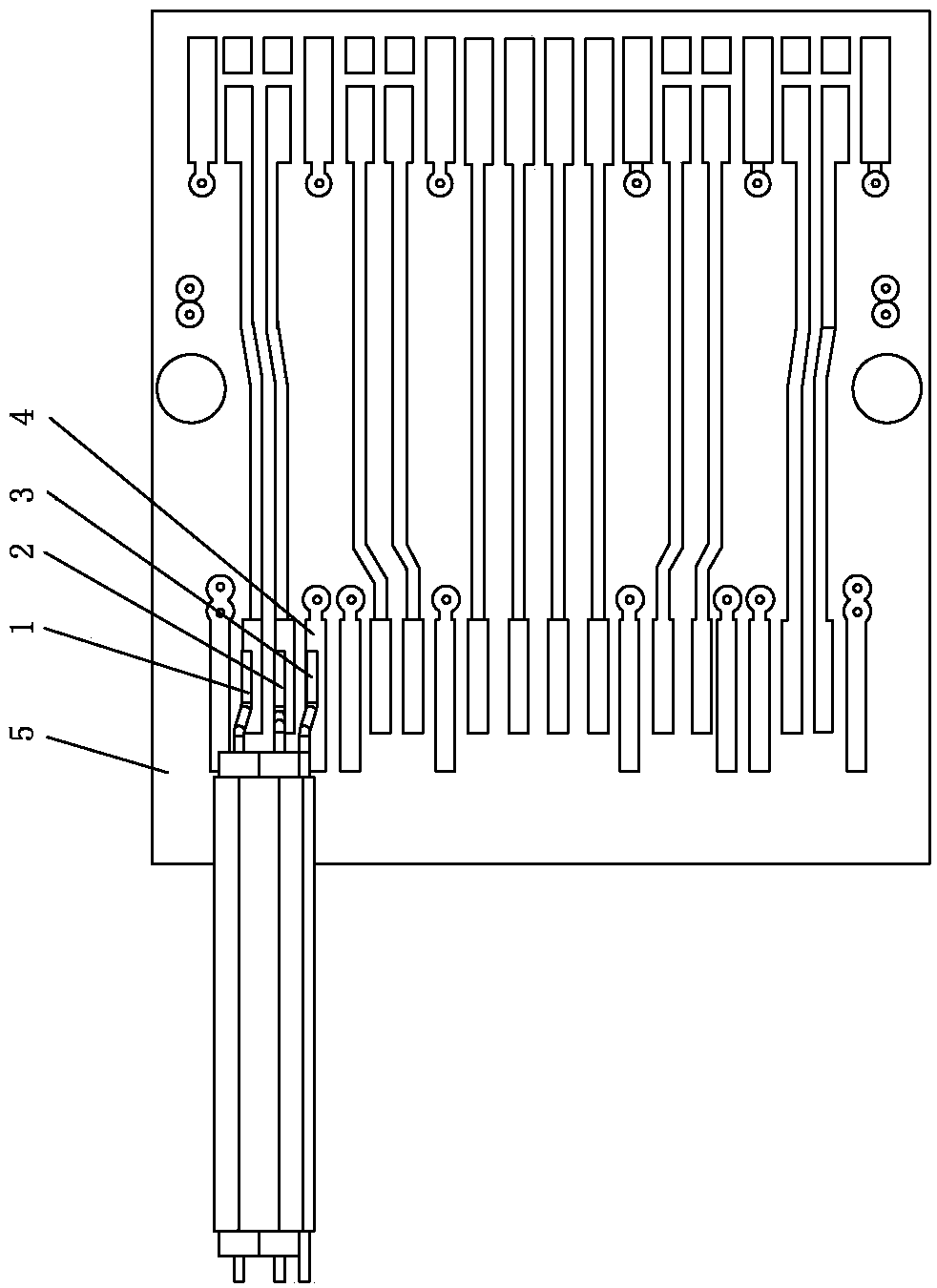

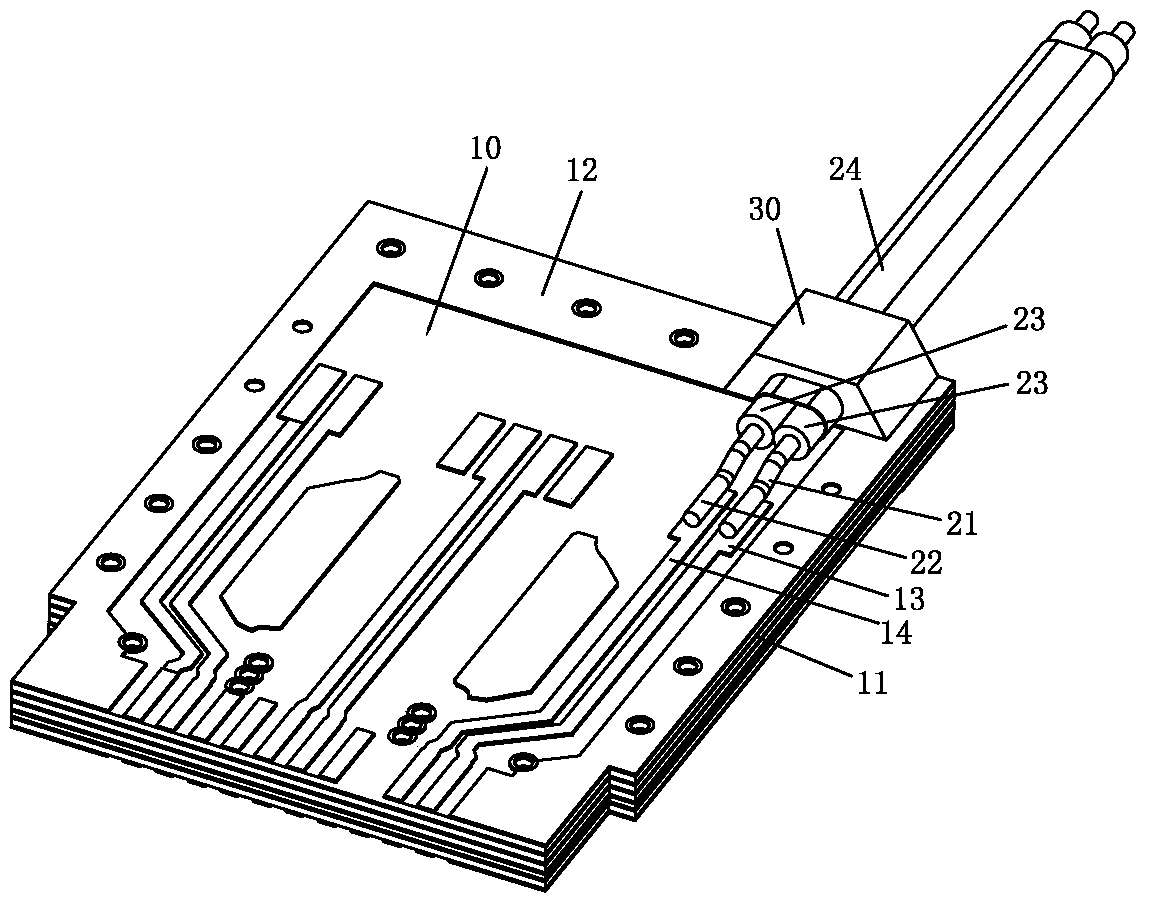

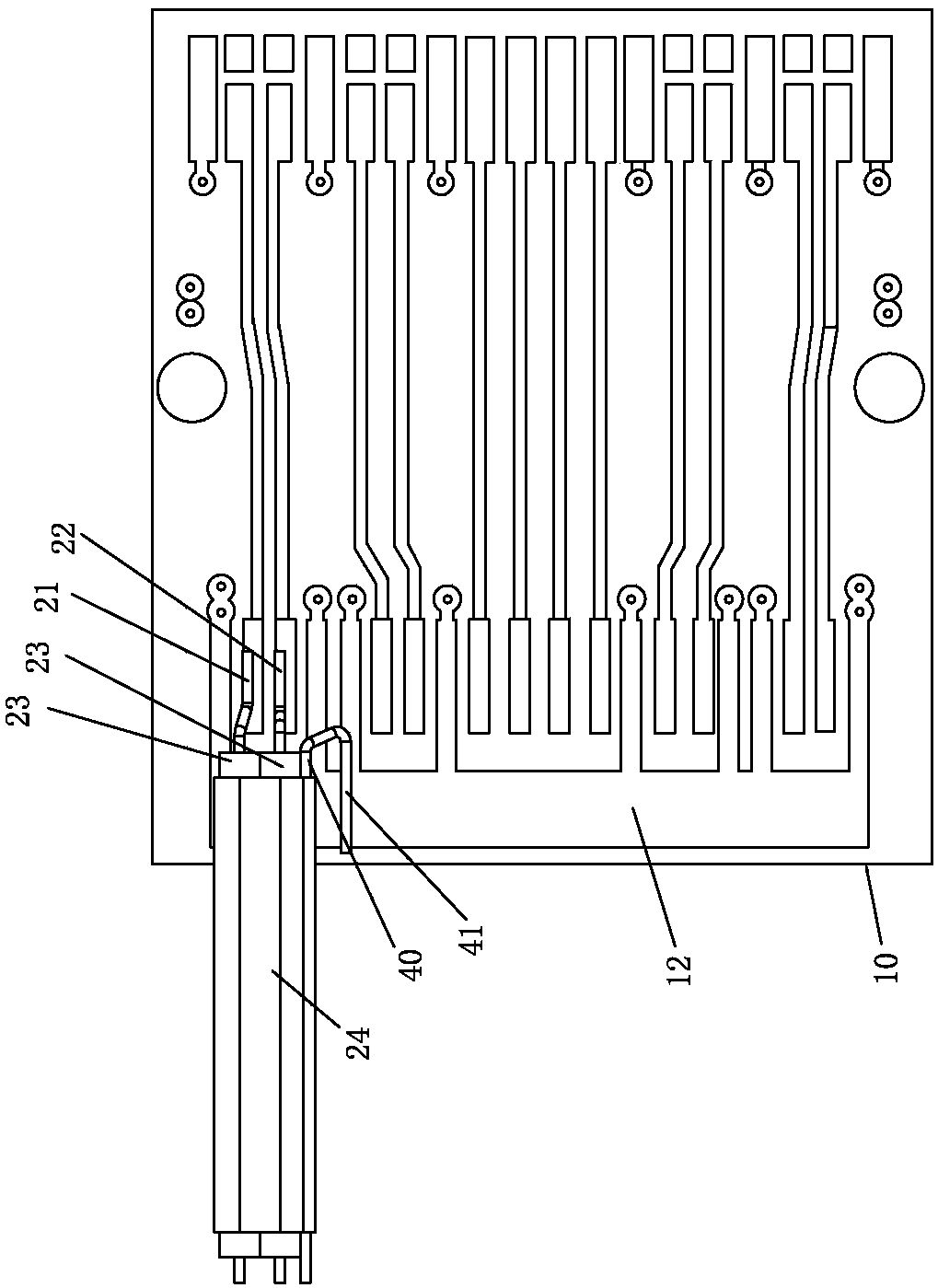

[0036] Please refer to Figure 2 to Figure 6 As shown, it shows the specific structure of two main embodiments of the present invention, which mainly solves the problem that the grounding wire in the prior art needs to be welded on the PCB board 10 in steps, and there are unstable changes during manual work. The grounding wire will be irregularly skewed, etc., which will cause problems such as uneven distance and unstable characteristic impedance.

[0037] Such as figure 2 As shown, it generally shows the specific structure of Embodiment 1 of the present invention, which includes a PCB board 10 and more than one cable (the expression "more than one cable" covers "one cable" , "two cables" and "multiple cables"), each cable has a differential signal line pair, an insulating layer 23 covering the outside of the differential signal line pair, and a metal shield covering the outside of the insulating layer 23 By 24 , the differential signal line pair includes a first differenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com