Synchronous rotation pressure-bearing type forming mold structure of magnetic field forming press

A molding die and synchronous rotation technology, applied in the field of synchronous rotary pressure-bearing molding die structure, to achieve the effects of good pressing effect, uniform density distribution and low rejection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

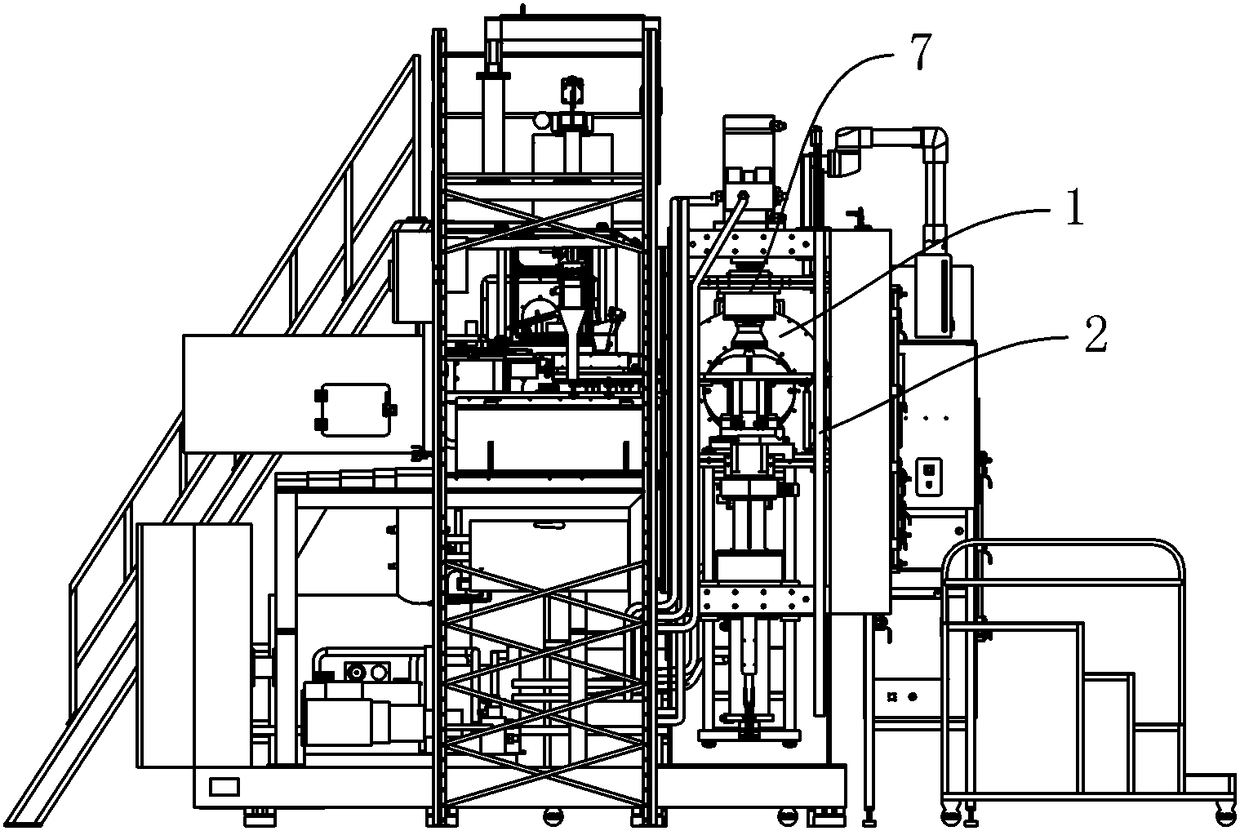

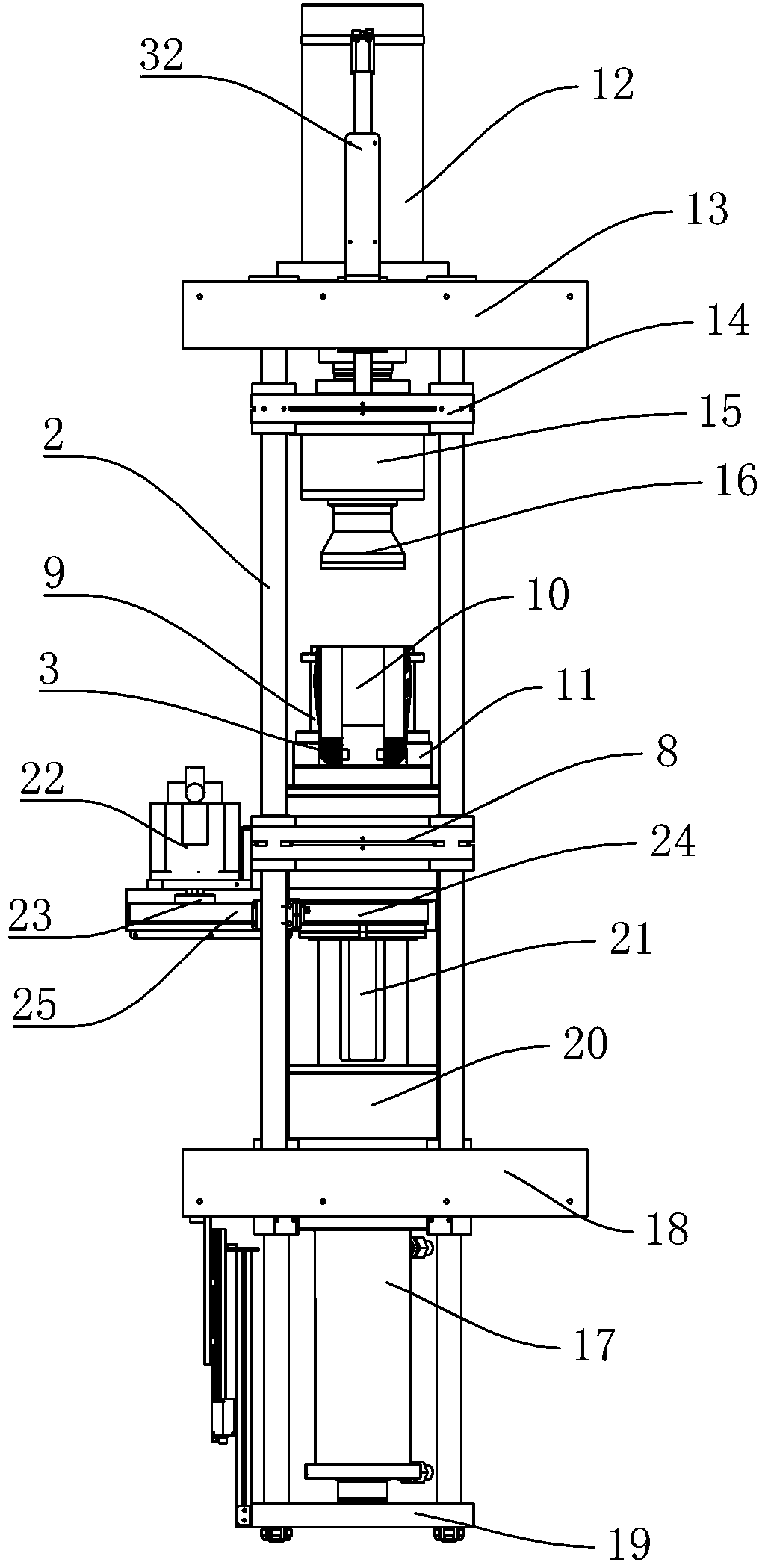

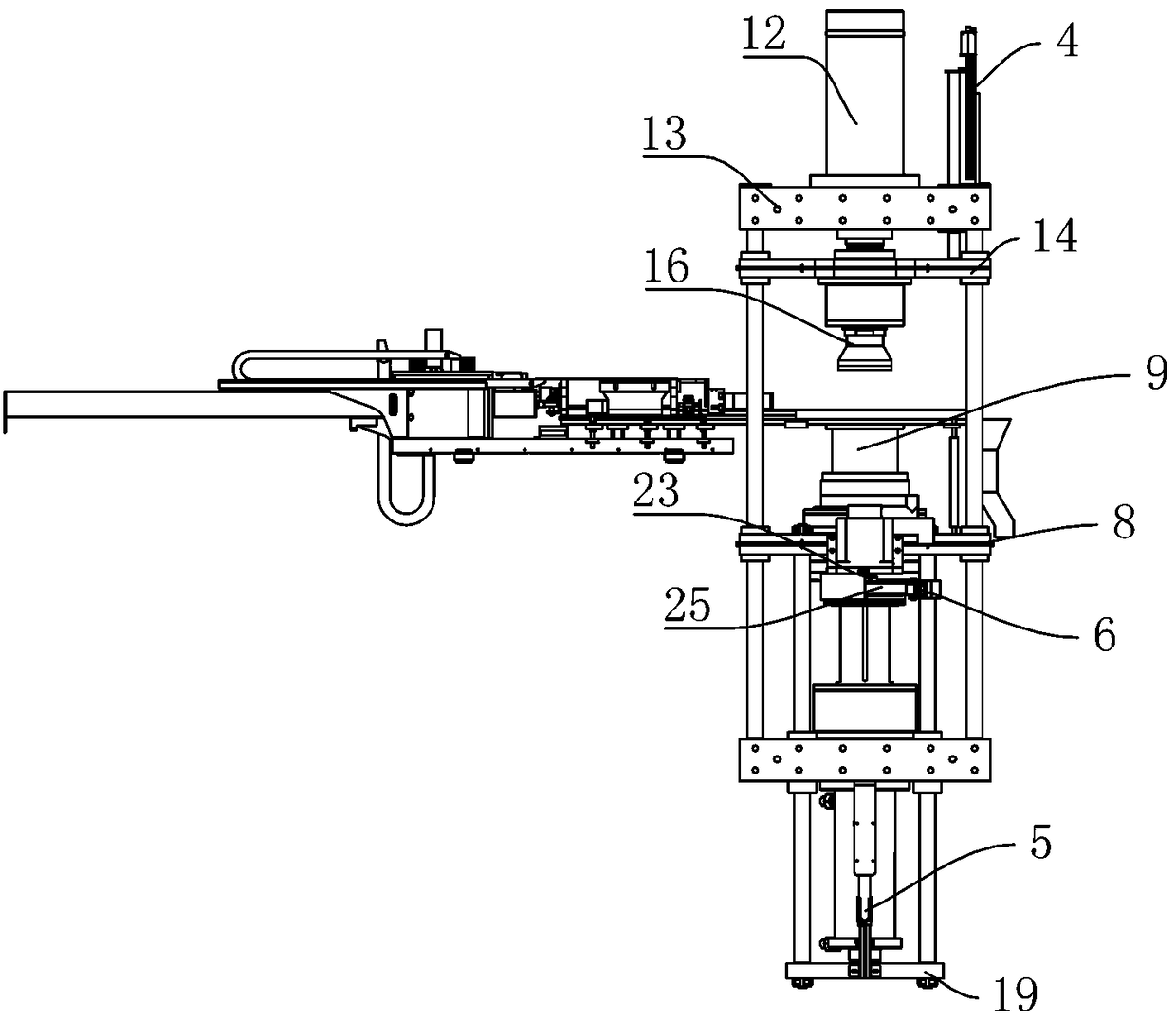

[0020] Examples, see Figure 1 to Figure 3 Shown: a synchronous rotating pressure-bearing forming mold structure of a magnetic field forming press, including a guide column 2, a middle guide plate 8, a forming mold 9, a mold frame 11, an upper punch, a lower punch, and a magnetic field coil 1, and a middle guide plate 8 is installed on the guide column 2, the mold base 11 is rotatably installed on the middle guide plate 8, the forming mold 9 is installed on the mold base 11, and a mandrel 10 is arranged inside the forming mold 9, and the mandrel 10 is installed on the mold base 11 , the upper punch and the lower punch are located at the upper and lower ends of the forming die 9 respectively, and the magnetic field coil 1 is located at the side of the forming die 9 . The upper punch includes an upper cylinder 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com