Teflon fine tube cutting equipment

A Teflon thin tube and equipment technology, which is applied in shearing machine equipment, metal processing equipment, pipe shearing devices, etc., can solve the problems of poor incision quality, easy to cut oblique openings, and difficult to control, and achieve good incision quality. , Improve length accuracy, eliminate the effect of bending or flattening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

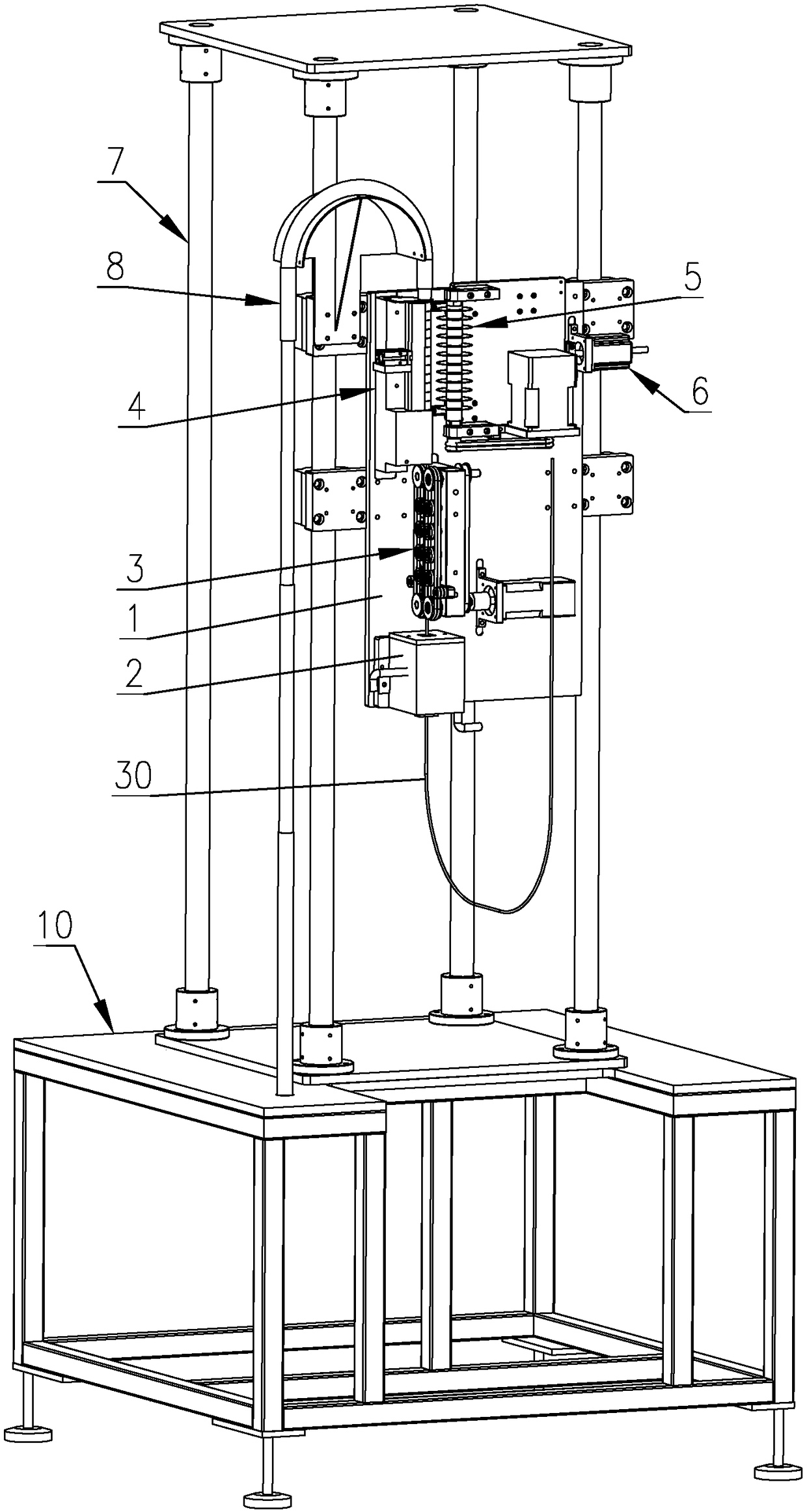

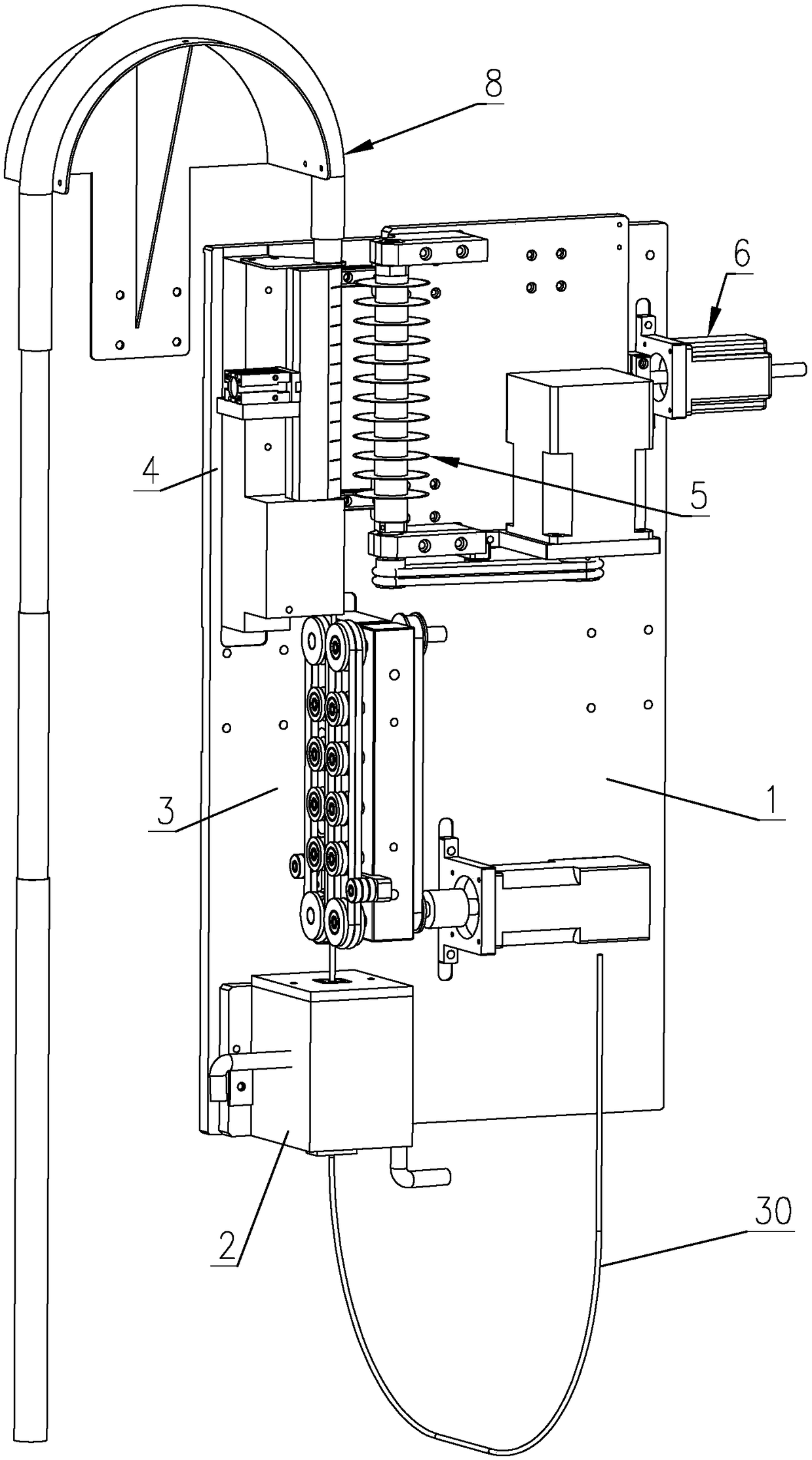

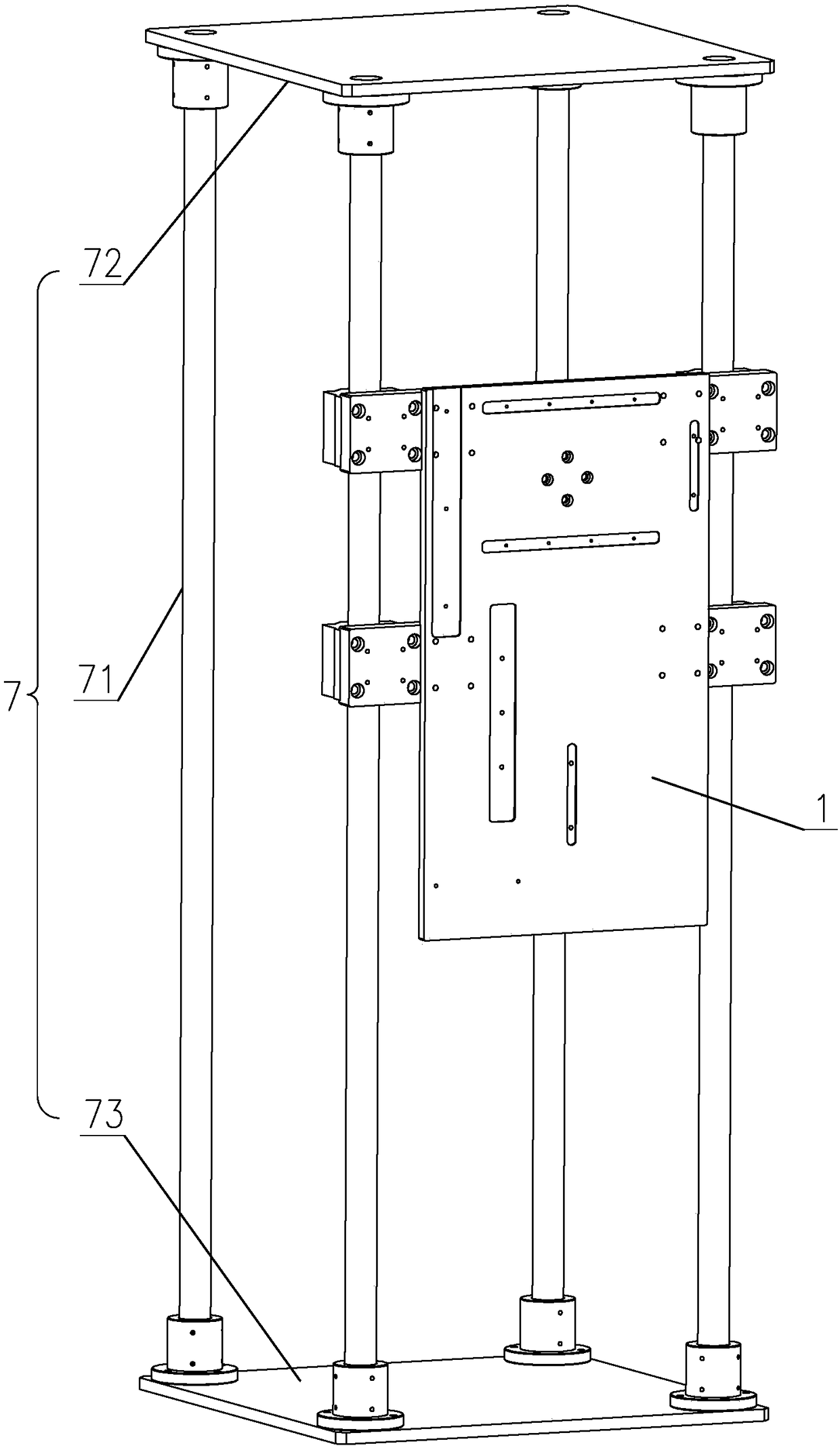

[0084] Such as figure 1 As shown, a Teflon thin tube cutting equipment includes a base 1, a cooling water tank 2, a conveying mechanism 3, a clamping mechanism 4, a cutting mechanism 5, a cutting driving mechanism 6, a supporting frame 7, an output mechanism 8, a machine Frame 10, collection box, and support frame 7 are provided with at least 2 support columns 71; Cooling water tank 2, conveying mechanism 3, clamping mechanism 4, cutting drive mechanism 6, output mechanism 8 are fixedly installed on base 1 respectively, and cutting mechanism 5 Fixedly installed on the cutting drive mechanism 6, the support frame 7 is fixedly installed on the frame 10, the base 1 is fixedly installed on the support column 71, the inlet of the output mechanism 8 communicates with the outlet of the clamping mechanism 4, and the collection box is placed on the frame 10; the Teflon thin tube 30 passes through the cooling water tank 2 and is inserted into the conveying mechanism 3, and the conveying...

Embodiment approach 2

[0092] Such as Figure 10 , Figure 11 As shown, the second embodiment is basically the same as the first embodiment, except that the clamping mechanism 4 is different. The clamping mechanism 4 of the second embodiment includes a main clamping block 44, and a plurality of secondary clamps are arranged on the front of the main clamping block 44 The holding block 45, the front of the main holding block 44 and the auxiliary holding block 45 are all provided with arc-shaped grooves 431 for clamping the Teflon thin tube 30, and the main holding block 44 side is provided with a breach 432 for cutting , the secondary clamping block 45 and the gap 432 are designed according to the length of the Teflon thin tube 30 after being cut, and a plurality of them can be evenly designed, and the second embodiment of the present invention is designed to be 12; the main clamping block 44 passes through the main clamping The mounting block 46 is fixedly mounted on the base 1 .

[0093] The prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com