Repeated filling type packaging bag nitrogen filling device

A technology of packaging bags and inflatable tubes, which is applied in packaging, transportation and packaging, and special packaging items, etc., can solve the problems of material expiration, waste, packaging filling, nitrogen content and low concentration, etc., to avoid waste, extend shelf life, and improve The effect of packaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

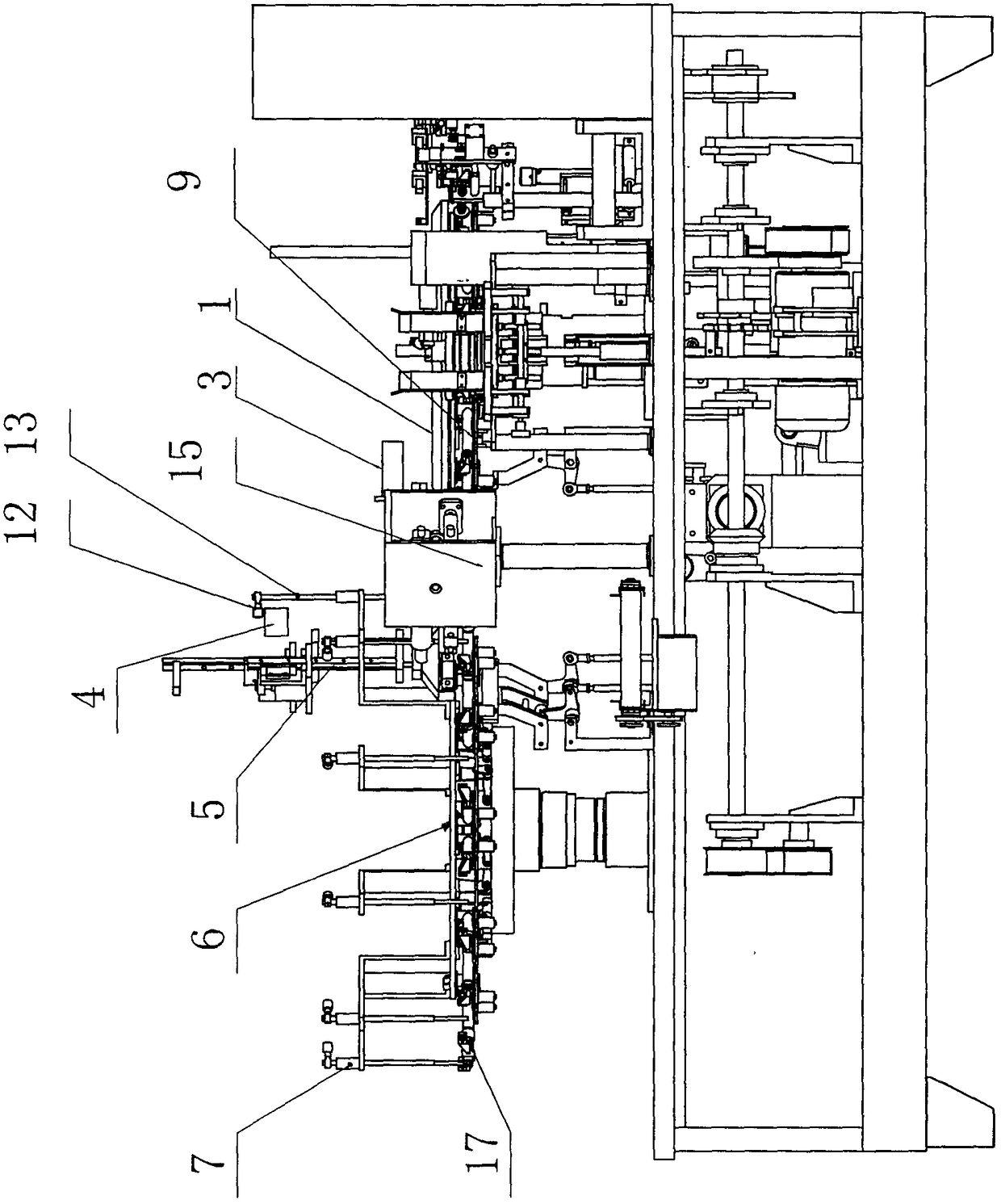

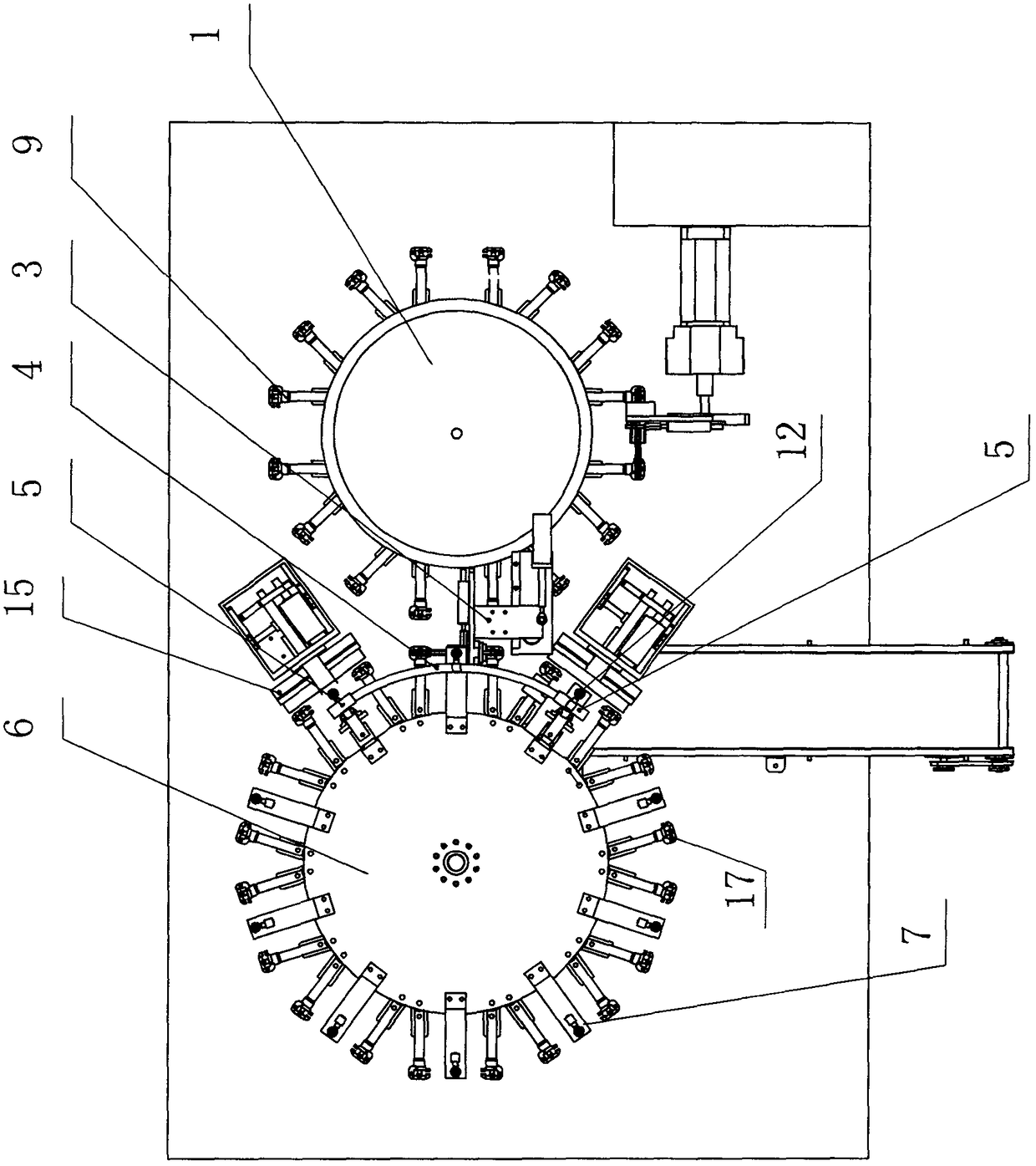

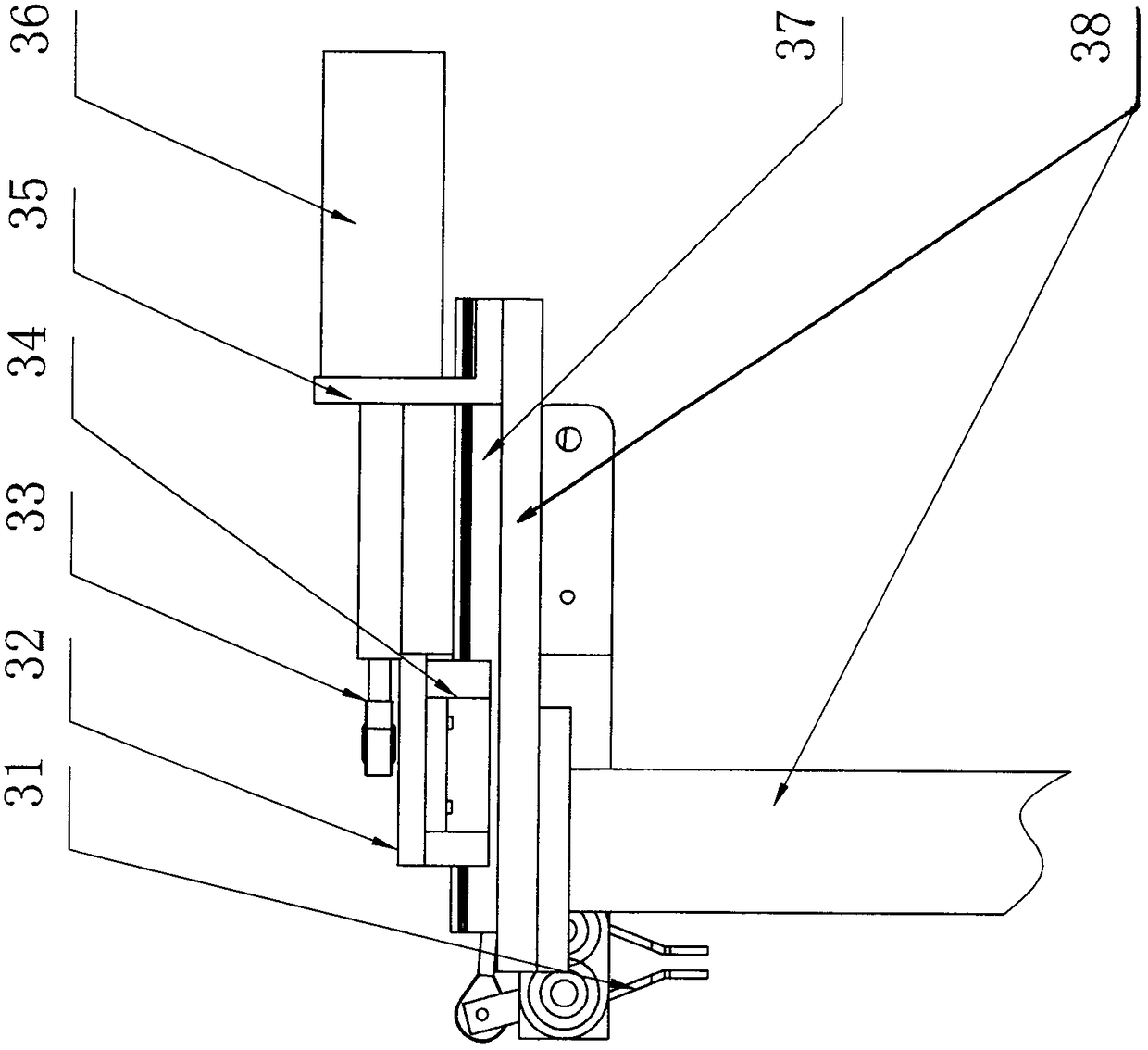

[0015] refer to figure 1 , figure 2 , Figure 5 It can be seen that the multi-filling packaging bag nitrogen filling device of the present invention includes a frame 6 (with a rotating function, which can be an inflatable turntable), an inflatable sub-clamp mechanism 17 (several), on the frame 6, and Between the left sub-clamp and the right sub-clamp of the inflatable sub-clamp mechanism 17, an inflation tube 13 is installed (by the inflatable support 14), and a roller 12 is installed on the upper end of the inflation tube 13 (by the fastening block 10). ; On the frame 6, a rolling plate 4 is installed above the inflation pipe 13, and the roller 12 can roll on the rolling plate 4, at the end side of the rolling plate 4 (left side , the right side all) are equipped with inflatable tube lifting mechanism 5, pocket encapsulation mechanism 15.

[0016] Wherein, one end of the top of the inflation pipe 13 is connected to the nitrogen source through the air supply pipe 11 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com