Method for eliminating warped skin on surface of hot alloy steel

A technology of alloy steel and warped skin, which is applied in the field of steelmaking technology, can solve the problem of warped skin on the surface of thermal alloy steel, and achieve the effect of eliminating warped skin defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

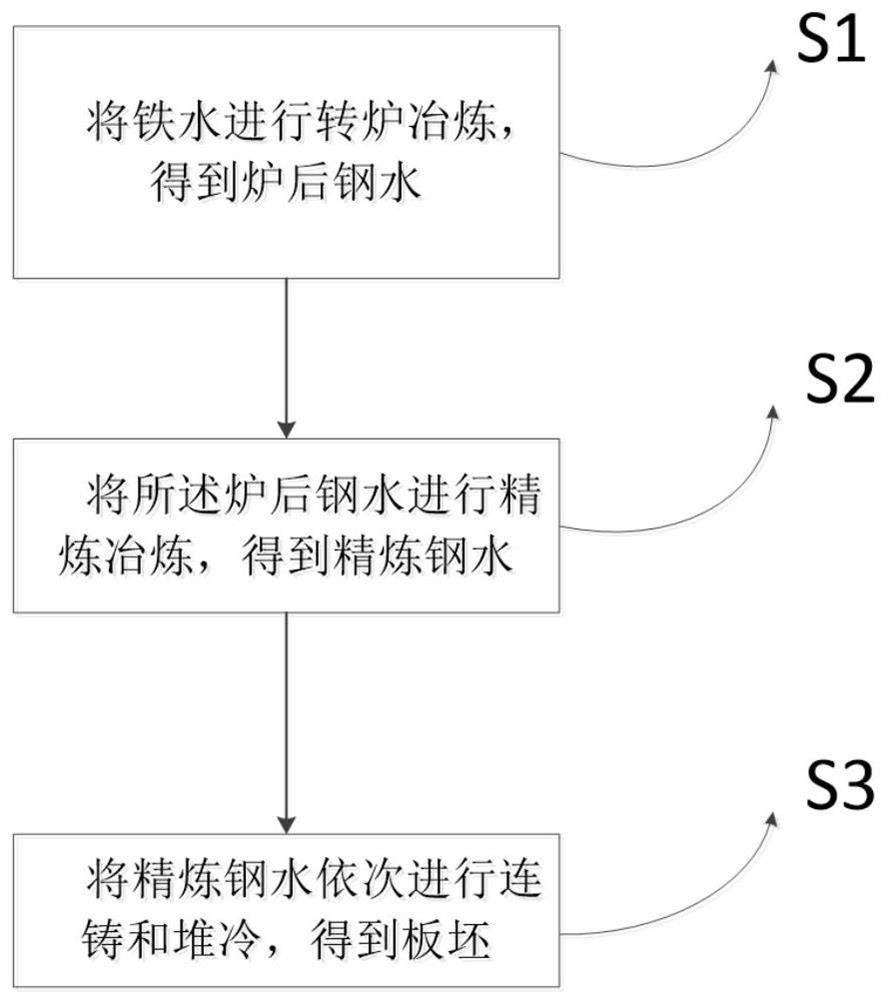

Method used

Image

Examples

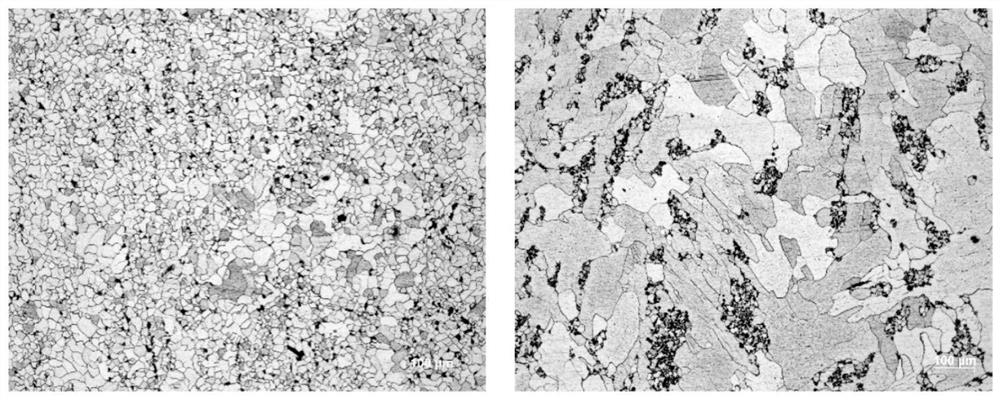

Embodiment 1

[0057] A method for controlling warped skin defects on the surface of alloy heat series steel. The Si content of the molten iron entering the furnace is 0.25%, the temperature of the molten iron is 1350°C, and the KR slag removal rate is guaranteed to be 96%; the bottom blowing mode of the converter adopts the "full argon blowing" mode , conventional smelting bottom blowing flow rate 1200Nm 3 / h, the nitrogen content after the converter furnace is 25ppm; after the ladle reaches the refining station, the argon blowing time is 3min, and the argon flow rate during the smelting period is 600Nm 3 / h, nitrogen increase of 4ppm in the refining process; continuous casting casting section 1300mm, casting speed 1.4m / min, argon flow rate of ladle casing 25L / min, continuous casting nitrogen increase of 3ppm, nitrogen content of finished steel is 32ppm; slab adopts stack cooling Process, the stack cooling time is 5 hours, the billet temperature after stack cooling is about 560°C, and the f...

Embodiment 2

[0059] A method for controlling warped skin defects on the surface of alloy heat series steel. The Si content of molten iron entering the furnace is 0.30%, the temperature of molten iron is 1360°C, and the KR slag removal rate is guaranteed to be 97%. The bottom blowing mode of the converter adopts the "full argon blowing" mode , the late blowing flow rate of semi-steel smelting converter bottom blowing is 850Nm 3 / h, using slag retention operation, the nitrogen content after the converter furnace is 26ppm; after the ladle reaches the refining station, the argon blowing time is 3.5min, and the argon flow rate during the smelting period is 500Nm 3 / h, nitrogen increase of 5ppm during refining process; continuous casting casting section 1400mm, casting speed 1.3m / min, argon gas flow rate of ladle casing 25L / min, continuous casting nitrogen increase of 2ppm, nitrogen content of finished steel is 33ppm; slab adopts stack cooling Process, the stack cooling time is 6h, the billet te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com